2.

Keylever

Pawl

to Interposer Clearance

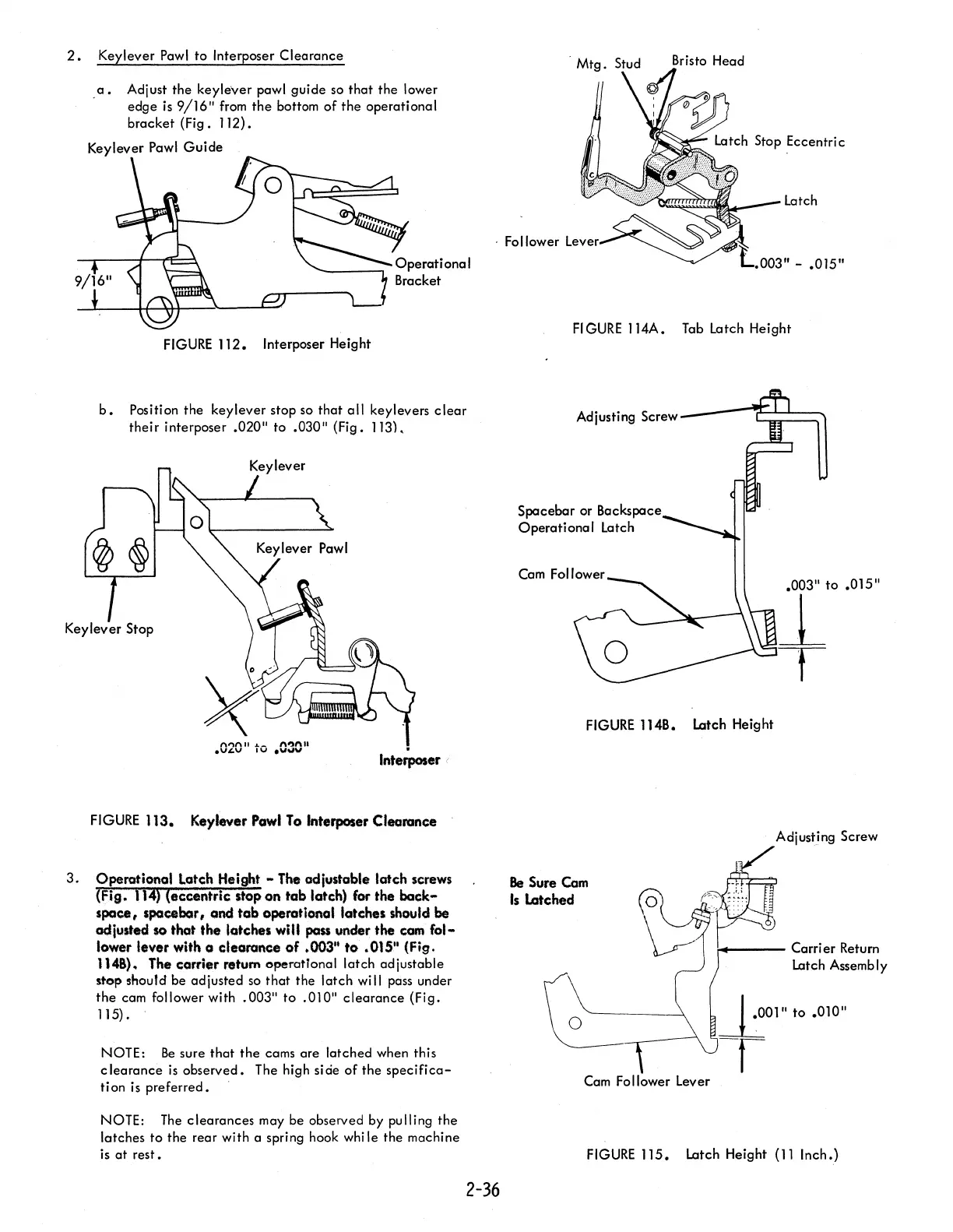

a.

Adjust the keylever pawl guide

so

that the lower

edge

is

9/16"

from

the bottom of the operational

bracket (Fig. 112).

Keylever

Pawl

Guide

Bristo Head

latch

. Follower

FIGURE

112.

Interposer Height

b.

Position the key lever stop

so

that

all

keylevers

clear

their interposer .020" to .030" (Fig. 113).

n",n

II.L_

n"2l\l1

•

U~V

IV

.u'-'V

.

Interposer (

FIGURE

113. Keylever

Powl

To

Interposer Clearance

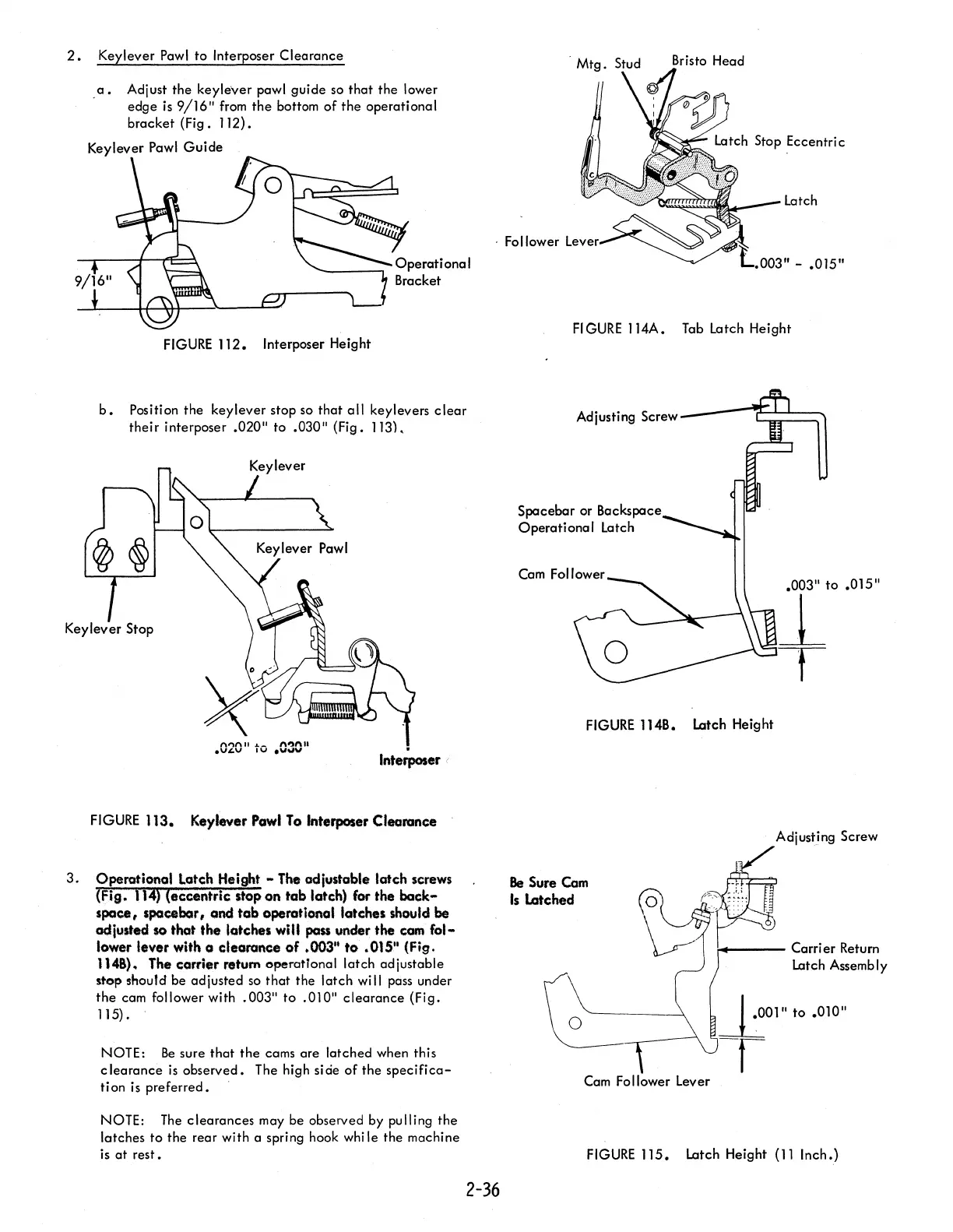

3.

Operational

Latch Height - The odjustable

latch

serews

(Fig.

114)

(eccentric

stop

on

tab

latch) for

the

back-

space,

spacebar,

and

tab

operational latches should

be

adjusted so thot

the

latches

will

pass under

the

cam

fol-

lower lever with a

clearance

of

.003" to .015" (Fig.

1146). The

carrier

retum operational latch adjustable

stop should be adjusted

so

that the latch

wi

II

pass under

the

cam follower with .003" to .010" clearance (Fig.

115) .

NOTE:

Be

sure that the cams are latched when this

clearance

is

observed. The high side of the

specifica-

tion

is

preferred.

NOTE:

The

clearances may be observed by pulling the

latches to the rear with a spring hook

whi

Ie

the machine

is

at

rest.

2-36

003" -

.015"

FIGURE

114A.

Tab

Latch Height

Adjusting

Screw----C:;===~

Spacebar or Backspace

Operational Latch

.003" to .015"

~

T

FIGURE

1148. Latch Height

Be

Sure

Cam

Is

Latched

Cam

Follower Lever

Adjusting Screw

~---

Carrier Return

latch

Assemb

Iy

~Olll

to .010"

-r

FIGURE

115. Latch Height

(11

Inch.)

Loading...

Loading...