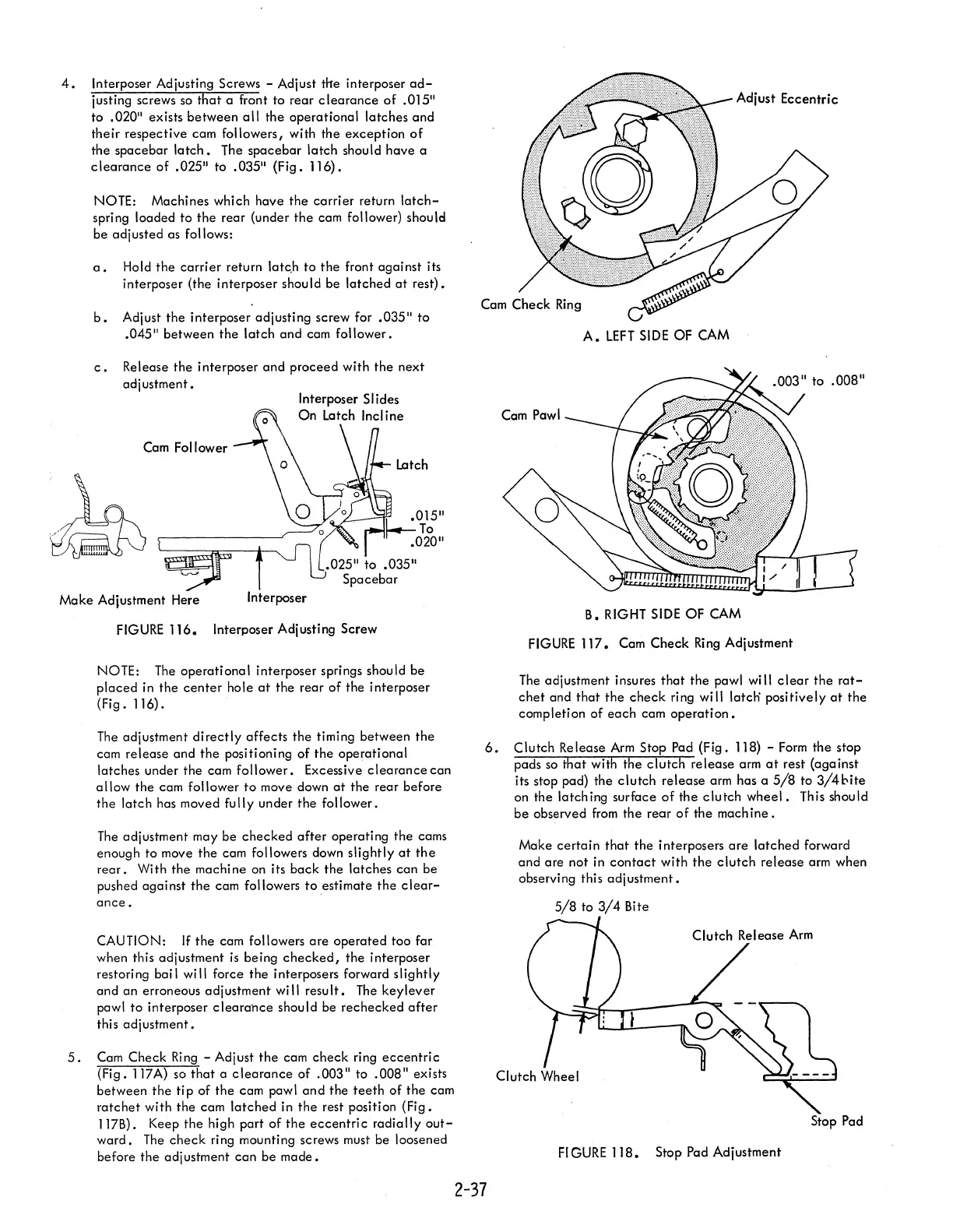

4.

Interposer Adjusting Screws - Adjust the interposer

ad-

justing screws

so

that

a front to rear

clearance

of

.015"

to .020" exists between

all

the operational latches and

their respective cam followers, with the exception

of

the spacebar

latch.

The

spacebar

latch should have a

clearance

of

.025" to .035" (Fig. 116).

NOTE: Machines which have the

carrier

return

latch-

spring loaded to

the

rear (under

the

cam follower) should

be adjusted as follows:

a.

Hold

the

carrier

return latc.h to

the

front against its

interposer (the interposer should be latched

at

rest).

b.

Adjust the interposer adjusting screw for

.035"

to

.045"

between

the

lotch and cam follower.

c.

Release the interposer

and

proceed with

the

next

adjustment.

Cam Follower

I.£Itch

Make Adjustment Here

Interposer

FIGURE

116.

Interposer Adjusting Screw

NOTE:

The

operational interposer springs should be

placed

in

the

center

hole

at

the rear

of

the interposer

(Fig. 116).

The

adjustment

directly

affects

the

timing between the

cam release and

the

positioning

of

the

operational

latches under the cam

follower.

Excessive

clearance

can

a

II

ow

the cam follower

to

move down

at

the rear before

the

latch has moved fully under

the

follower.

The

adjustment may be

checked

after

operating the cams

enough to move

the

cam followers down slightly

at

the

rear.

With the machine on its back

the

latches can be

pushed against

the

cam followers

to

estimate

the

clear-

ance.

CAUTION:

If

the

cam followers

are

operated too far

when this adjustment

is

being

checked,

the interposer

restoring bail will force

the

interposers forward slightly

and an erroneous adjustment will

result.

The

keylever

pawl

to

interposer

clearance

should be rechecked

after

this adjustment.

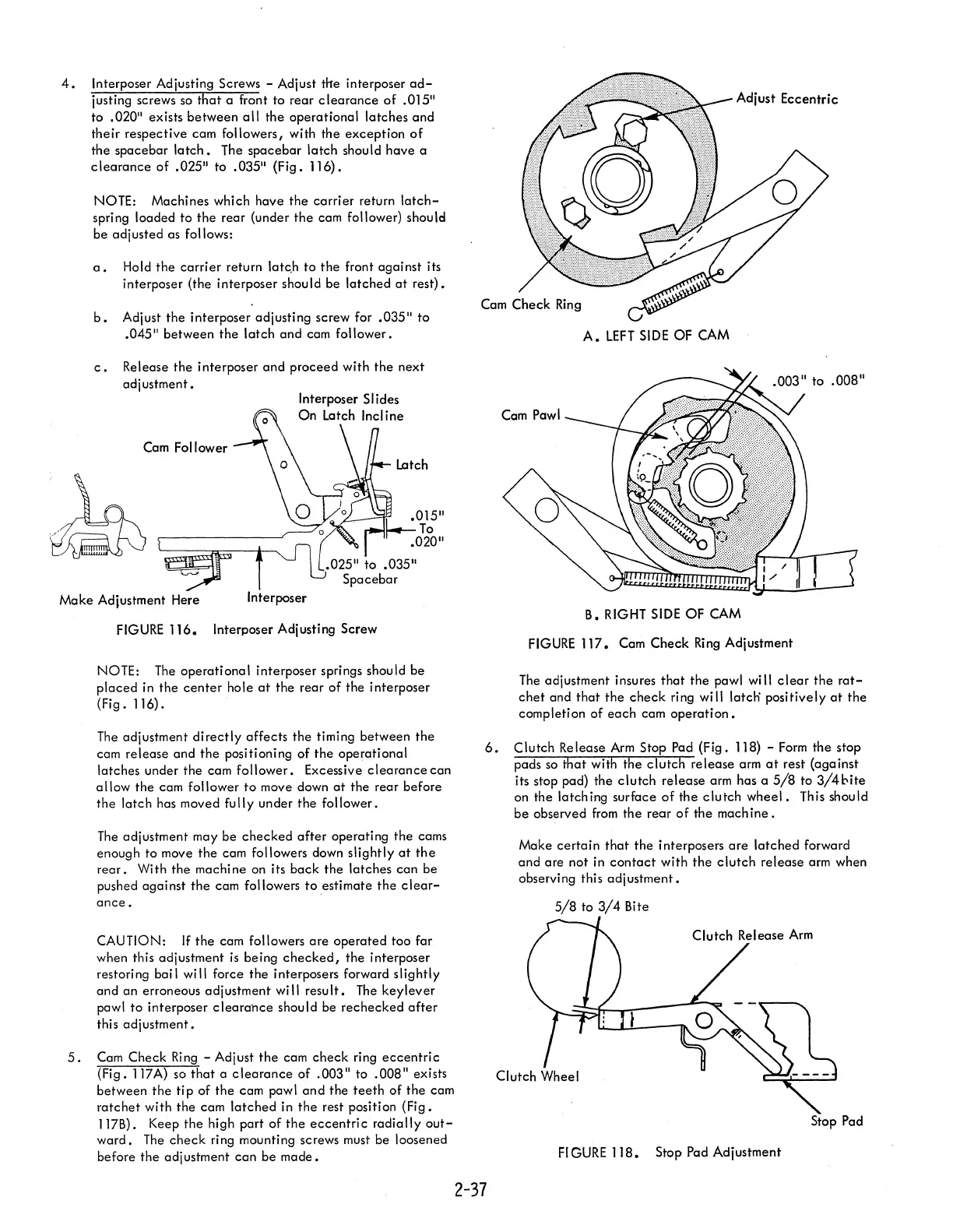

5.

Cam Check

Ring

- Adjust

the

cam check ring

eccentric

(Fig. 117A) so

that

a

clearance

of

.003"

to

.008"

exists

between

the

tip

of

the

cam pawl

and

the

teeth

of

the

cam

ratchet

with

the

cam

latched

in

the

rest position (Fig.

117B). Keep

the

high

part

of

the

eccentric

radially

out-

ward.

The

check

ring mounting screws must be loosened

before

the

adjustment

can

be

made.

Adjust Eccentric

A.

LEFT

SIDE

OF CAM

B. RIGHT

SIDE

OF CAM

FIGURE

117.

Cam Check

Ring

Adjustment

The

adjustment insures

that

the pawl will

clear

the

rat-

chet

and

that

the

check

ring will latch' positively

at

the

completion

of

each

cam

operation.

6.

Clutch Release

Arm

Stop Pad (Fig. 118) -

Form

the

stop

pads

so

that

with the

clutch

release arm

at

rest (against

its stop pad) the

clutch

release

arm has a

5/8

to 3/4l:-ite

on the latching surface

of

the

clutch

wheel.

This should

be

observed

from

the

rear

of

the

machine.

2-37

Make

certain

that

the

interposers

are

latched

forward

and

are

not in

contact

with

the

clutch

release arm when

observing this

adjustment.

5/8

to

3/4

Bite

Stop Pad

FIGURE

118.

Stop Pad Adjustment

Loading...

Loading...