7.

8.

'"

The

support

is

secured to the machine power frame by

two binding screws

at

each

end.

Elongated holes

inthe

machine powerframe enables the support to be adjusted

vertically.

This

adjustment serves the same purpose as

the

carrier

buffers on the

early

level machines.

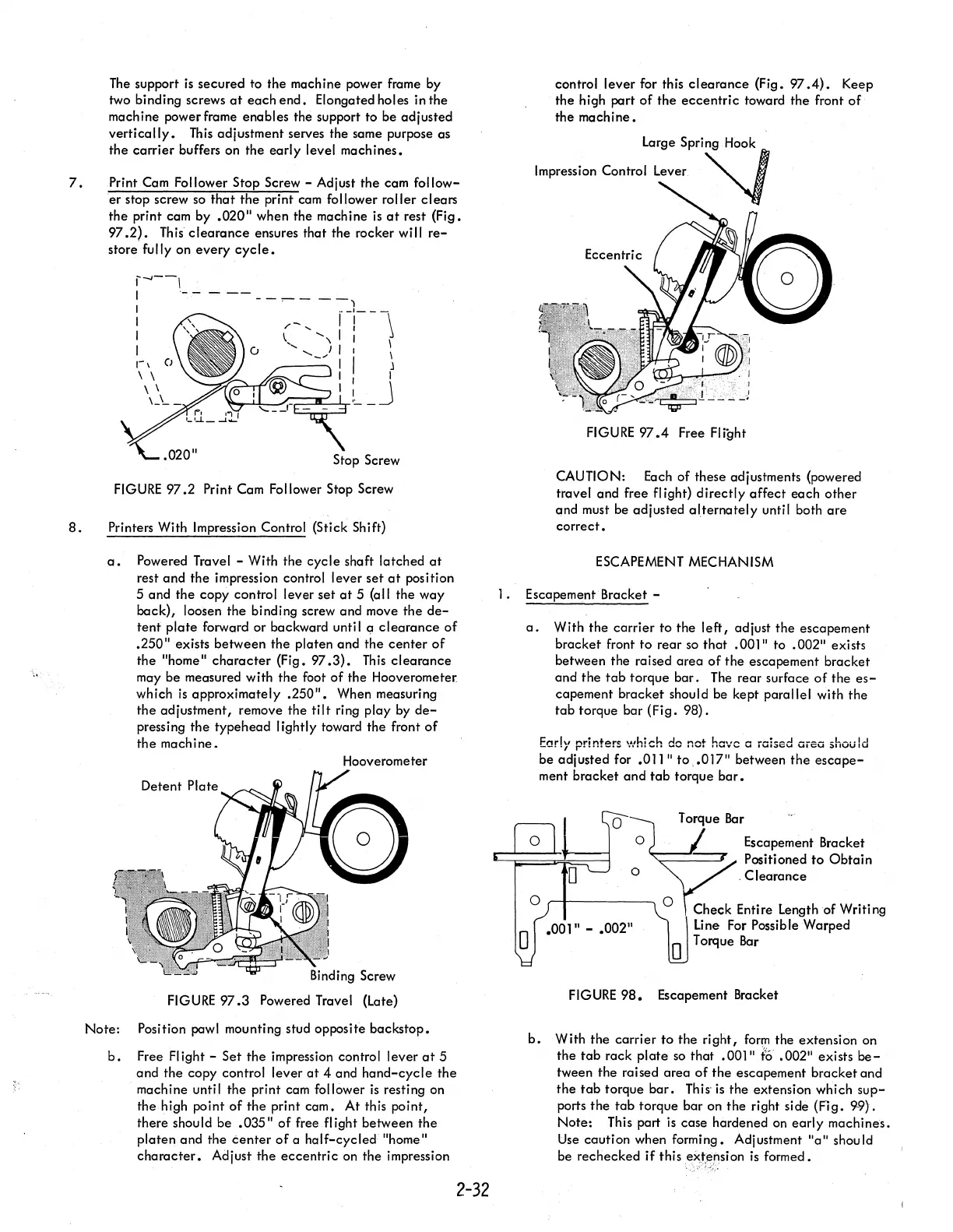

Print Cam Follower Stop Screw - Adjust the cam

follow-

er

stop screw so

that

the

print cam follower roller clears

the

print cam by

.020"

when the machine

is

at

rest (Fig.

97.2).

This

clearance

ensures that the rocker will

re-

store fully on

every

cycle.

,--,,--\

I

'-

- -

--

___

_

FIGURE

97.2

Print Cam Follower Stop Screw

Printers With Impression Control (Stick Shift)

a.

Powered Travel - With the

cycle

shaft latched

at

rest

and

the impression control lever

set

at

position

5 and the copy control lever

set

at

5 (all the way

back), loosen the binding screw and move

the

de-

tent

plate

forward or backward unti I a

clearance

of

.250"

exists

between

the

platen

and

the

center

of

the "home"

character

(Fig.

97.3).

This

clearance

may be measured with the foot

of

the Hooverometer

which

is

approximately

.250".

When measuring

the

adjustment, remove

the

tilt

ring play

by

de-

pressing

the

typehead I ightly toward the front

of

the

machine.

Hooverometer

FIGURE

97.3

Powered Travel (Late)

Note:

Position pawl mounting stud opposite

backstop.

b.

Free Flight -

Set

the

impression control

lever

at

5

and

the copy control lever

at

4 and

hand-cycle

the

machine until the print cam follower

is

resting on

the high point

of

the

print cam.

At

this point,

there should be

.035"

of

free flight between

the

platen

and

the

center

of

a

half-cycled

"home"

character.

Adjust the

eccentric

on the impression

2-32

control

lever

for this

clearance

(Fig.

97.4).

Keep

the high part

of

the

eccentric

toward

the

front

of

the

machine.

Large Spring Hook

'mp,",,;o"

CO"''"'

lm,

""J

FIGURE

97.4

Free Flight

CAUTION:

Each

of

these adjustments (powered

travel and free

fl

ight)

directly

affect

each

other

and must be adjusted

alternately

until both

are

correct.

ESCAPEMENT MECHANISM

].

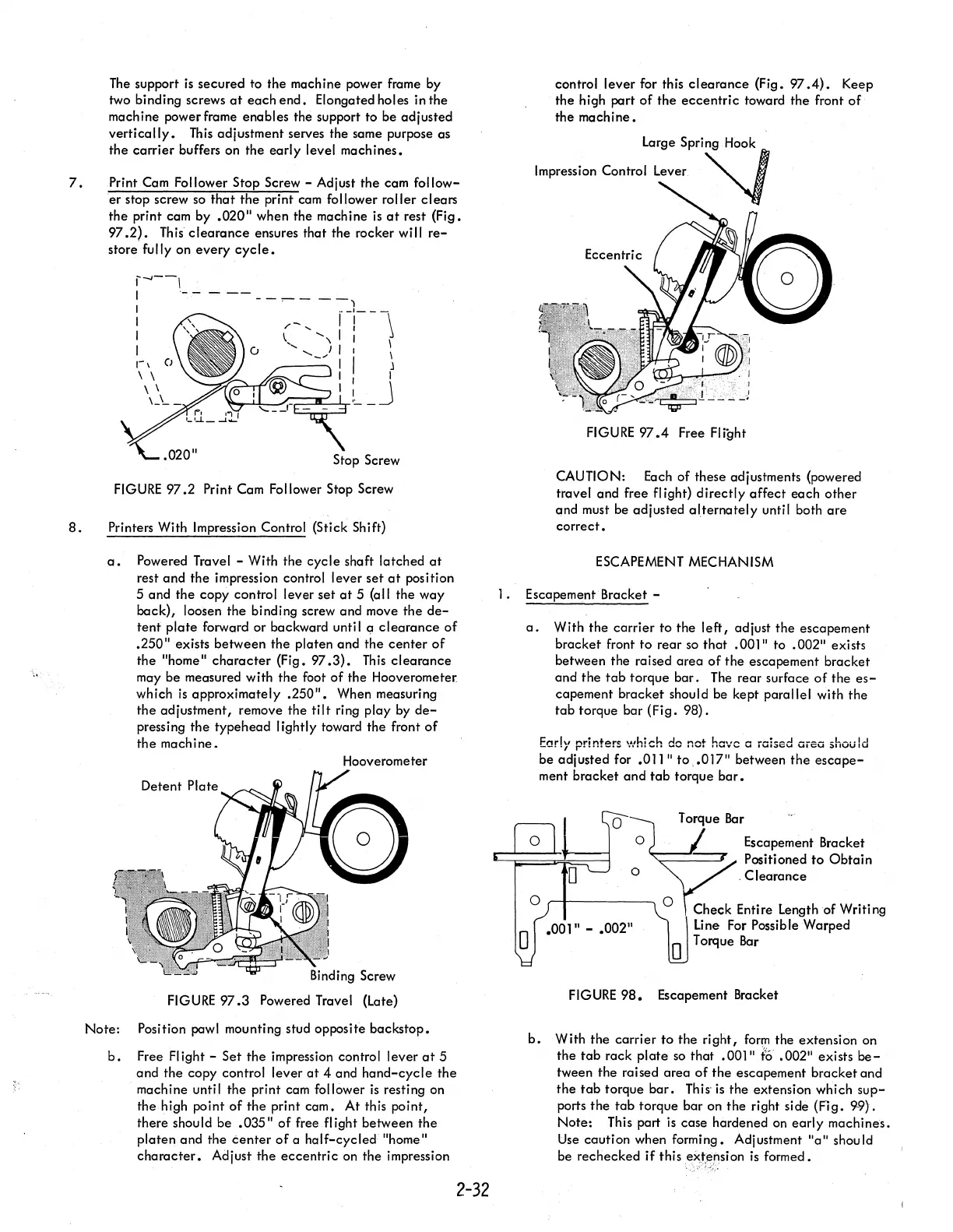

Escapement Bracket -

a.

With

the

carrier

to

the

left,

adjust

the

escapement

bracket

front

to

rear

so

that

.00]"

to

.002"

exi sts

between the raised

area

of

the

escapement

bracket

and

the

tab

torque

bar.

The

rear surface

of

the

es-

capement

bracket

should be kept parallel with

the

tab

torque bar (Fi

g.

98).

Early

printers

\Afhich

do

not have a iaised

Oieo

should

be adjusted for

.011"

to,.0]7"

between

the

escape-

ment

bracket

and

tab

torque

bar.

o

o

Escapement Bracket

Positioned

to

Obtain

.

Clearance

o

"r-------~O

Check Entire Length of Writing

Line For Possible Warped

.00111

-

.00211

o Torque

Bar

FIGURE

98.

Escapement Bracket

b.

With

the

carrier

to

the

right,

form

the extension on

the

tab

rack

plate

so

that

.00]"

to

.002"

exists

be-

tween the raised

area

of

the

escapement

bracket

and

the

tab

torque

bar.

This

is

the extension which

sup-

ports

the

tab

torque bar on

the

right

si

de (Fi

g.

99).

Note:

This part

is

case hardened

on

early

machines.

Use

caution when forming. Adjustment

"a"

should

be rechecked

if

this

eX,t,ension

is

formed.

Loading...

Loading...