Note:

Check

as follows.

Half-cycle

the

character

and

remove

detent

from

the

head.

Take the play out

of

th-e

head in a clockwise

direction.

Allow

the

detent

to

re-

turn slowly, and observe

the

point

the

detent

strikes or

enters

the

skirt.

Bandwidth equals

the

difference between

the

best and worst

character.

DETENTING

I

1.

\

2.

Print-shaft timing: The

detent

must

enter

and

leave

the

head without hitting

the

skirt.

Check

by manually hal

f-

cycling.

Use a

-5,

home, and a +5

character.

The skirt

clearance

should be

.025"

-

.035"

in a

2-tilt

position. When both dp.tents

are

engaged

fully in

their

respective

notches,

there

should be

.001"

minimum

mo-

tion

of

the

detent-cam

follower with respect

to

the

detent

lever.

THIRD

INSPECTION

PERIOD

)

SELECTION MAGNET UNITS

--

SCOPE

PROCEDURE

,\.

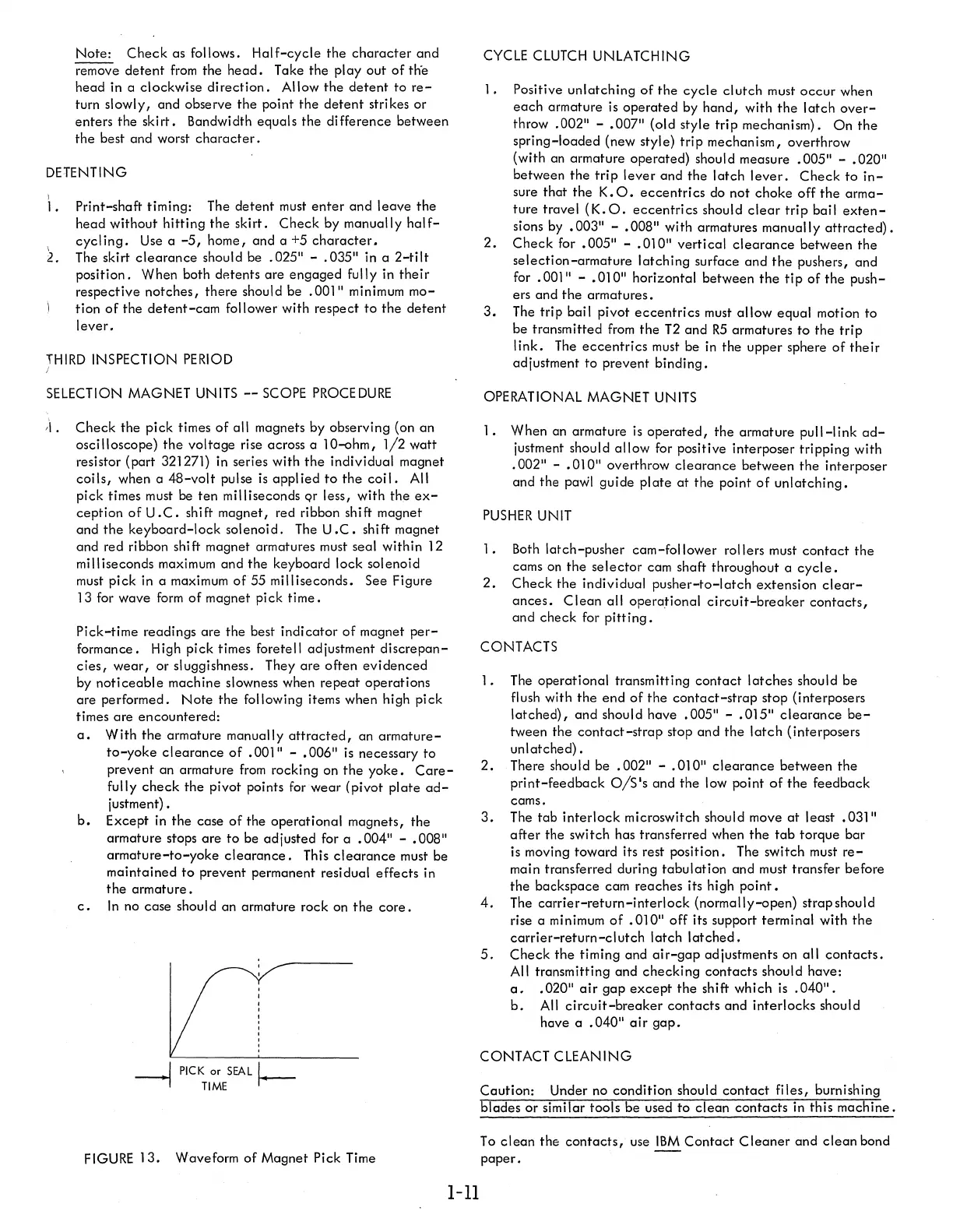

Check

the

pick times

of

all magnets by observing (on an

osci lIoscope)

the

voltage

rise across a 1 O-ohm,

1/2

watt

resistor (part 321271) in series with

the

individual magnet

coi

Is, when a

48-volt

pulse

is

appl ied

to

the

coi

\.

All

pick times must be

ten

milliseconds

Qr

less, with

the

ex-

ception

of

U.C.

shift magnet, red ribbon shift magnet

and

the

keyboard-lock

solenoid. The

U.C.

shift magnet

and red ribbon shift magnet armatures must seal within 12

milliseconds maximum and

the

keyboard lock solenoid

must pick in a maximum

of

55 milliseconds. See Figure

13 for wave

form

of

magnet pick

time.

Pick-time

readings

are

the

best

indicator

of

magnet

per-

formance. High pick times foretell adjustment

discrepan-

cies,

wear,

or

sluggishness. They

are

often

evidenced

by

noticeable

machine slowness when

repeat

operations

are

performed.

Note

the following items when high pick

times

are

encountered:

a.

With

the

armature manually

attracted,

an

armature-

to-yoke

clearance

of

• 001" - • 006"

is

necessary

to

prevent an armature

from

rocking on

the

yoke.

Care-

fully

check

the

pivot points for Wear (pivot

plate

ad-

justment) •

b.

Except

in

the

case

of

the

operational magnets,

the

armature stops

are

to

be adjusted for a

.004"

- • 008"

armature-to-yoke

clearance.

This

clearance

must be

maintained

to

prevent permanent residual

effects

in

the

armature.

c.

In

no case should an armature rock on

the

core.

I

PICK

or

SEAL

I-

~

TIME

FIGURE

13.

Waveform

of

Magnet Pick Time

1-11

CYCLE

CLUTCH

UNLATCHING

1.

Positive

unlatching

of

the

cycle

clutch

must

occur

when

each

armature

is

operated

by

hand,

with

the

latch

over-

throw

.002"

-

.007"

(old style trip mechanism).

On

the

spring-loaded (new style)

trip

mechanism, overthrow

(with an armature operated) should measure

.005"

-

.020"

between

the

trip

lever

and

the

latch

lever.

Check

to

in-

sure that

the

K.O.

eccentrics

do not choke off

the

arma-

ture travel

(K.O.

eccentrics

should

clear

trip

bail

exten-

sions

by

• 003" - • 008" with armatures manually

attrocted).

2.

Check

for

.005"

-

.010"

vertical

clearance

between

the

selection-armature

latching surface and

the

pushers, and

for

.001"

-

.010"

horizontal between

the

tip

of

the

push-

ers and

the

armatures.

3.

The trip bail pivot

eccentrics

must

allow

equal

motion to

be transmitted

from

the

T2

and

R5

armatures

to

the

trip

link.

The

eccentrics

must be

in

the

upper sphere

of

their

adjustment to prevent

binding.

OPERATIONAL MAGNET UNITS

1.

When an armature

is

operated,

the

armature

pull-link

ad-

justment should

allow

for positive interposer tripping with

.

002" - •

01

A"

overthrow

clearance

between

the

interposer

and the

pawl guide

plate

at

the

point

of

unlatching.

PUSHER

UNIT

1.

Both

latch-pusher

cam-follower rollers must

contact

the

cams

on

the

selector

cam shaft throughout a

cycle.

2.

Check

the individual

pusher-to-Iatch

extension

clear-

ances.

Clean

all operaHonal

circuit-breaker

contacts,

and check for

pitting.

CONTACTS

1.

The operational transmitting

contact

latches

should

be

flush with

the

end

of

the

contact-strap

stop (interposers

latched),

and

should have

.005"

-

.015"

clearance

be-

tween

the

contact-strap

stop and

the

latch

(interposers

unlatched)

•

2.

There shou

Id

be

.002"

- • 010"

clearance

between

the

print-feedback

O/S's

and

the

low point

of

the

feedback

cams.

3.

The

tab

interlock

microswitch should move

at

least

.031"

after

the

switch has transferred when

the

tab

torque bar

is moving toward its rest position. The switch must

re-

main transferred during

tabulation

and must transfer before

the

backspace cam reaches its high

point.

4.

The

carrier-return-interlock

(normally-open) strapshould

rise a minimum

of

.010"

off its support terminal with

the

carrier-return-clutch

latch

latched.

5.

Check

the

timing and

air-gap

adjustments on all

contacts.

All transmitting and

checking

contacts

should have:

a.

.020"

air

gap

except

the

shift which

is

.040".

b.

All

circuit-breaker

contacts

and interlocks should

have a

.040"

air

gap.

CONTACT CLEANING

Caution:

Under no condition should

contact

files,

burnishing

blades

or

similar tools be used to

clean

contacts

in this

machine.

To

clean

the

contacts,

use

IBM

Contact

Cleaner

and

clean

bond

paper.

Loading...

Loading...