MACHINE LOCKUP

d.

Binding

Operational

Shaft

19.0

Machine

Lockup

e.

Dry

or

binding Shift

Clutch

20.2

Motor Fails

to

Drive

19.1 The most common causes

of

Machine

Lockup'are:

~=-=-"""----::c-:~r-::--r:-::--:r:c:------:-:-:-;--:-T-

_____

Ll

~-,T-LhLeermaLcut~ut-Open,-

-----cr;-Ine--cyc-le--clufCn Spring may

be

broken,

out

of

2.

Dry motor

bearings.

adjustment

(Section

15.0),

or

is

in

need

of

lub-

rication.

b.

Idler

gear

binding.

Remove and

lubricate

with

#10

oil.

c.

Remove

the

type

element,

then

recheck

for

lock-

up.

If no lockup is

encountered,

a

II

type

head

motion adjustments

and

print shaft timing must be

checked.

d.

The Print

Sleeve

and bearings may be dry

or

worn.

e.

Binds in

the

Carrier

and

Rocker Assembly.

f.

Check

the

Print Cam Follower for bi.nds.

g.

Oversize

Cycle

Clutch

Pulley

and

Hub

Assem-

bly.

(Section

15.5)

h.

Shift Cam Back-Up Roller

adjustment.

(Section

4.8)

i.

Operation

Shaft binds

or

Shift Cam

adjustment.

(Section

4.0)

j.

Shift Spring

Clutch

is dry or requires

adjustment.

(Secti

on

4.0)

k.

Dry

center

bearing.

(Section

15.7).

FAI

LURE

TO

START

20.0

Failure

to

Start

If

motor

attempts

to

drive,

check:

20.1

Centrifugal

<;:Iutch Binding (See Also

21.3)

a.

I/O

PRI

NTER

CENTRI FUGAL CLUTCH

A

sintered

iron

pulley

with a

Mylar

® insert

and

nylon

clutch

pawls has

been

released

to

eliminate

motor

clutch

lockup and

pu

Iley

wear.

The nylon pawls

are

used to

eliminate

wear

on

the

teeth

of

the

bronze

pu Iley .

The

sintered

iron

pulley

has a

slightly

larger

in-

si

de

diameter

to

accept

the

Mylar

®

sleeve.

When

replacing

the

motor

pulley,

clean

the

mo-

tor

shaft

thorough

Iy

to

prevent

future

binding.

A

piece

of fine emery

cloth

may

be

used

while

run-

ning

the

motor.

Remove

any

abrasive

material,

using

IBM

cleaning

fluid,

prior to

assembly.

NO,TE:

If

emery

cloth

is

used to

clean

the

motor

shaft,

the

enti re

paw

I assemb

Iy

must

be

removed,

as

a

safety

hazard

is present

if

the

emery

cloth

contacts

the

moving pawls

and

springs.

Lubricate

the

new

sintered

iron

pulley

with

IBM

#10

oil

during

initial

assembly and

thereafter

as

required.

A

II

parts

necessary

to

convert

to

the

new

clutch

assembly

are

avai

lable

under B/M 1272045.

b.

Cycle

Clutch

Pulley

oversize.

c.

Dry

or

binding

Center

Bearing

(15.7).

20.3

Capacitor

Start

Motor

In

order

to

eliminate

problems

which

have

existed

with

the

shaded

pole motor

and

clutch,

an improved

capacitor

start

motor

is

avai

lable

for use in instances

where

repetitive

fai lures

have

been

encountered

with

the

previous

clutch

arrangement.

The new

cap-

acitor

start

motor uses a 4 mfd.

capacitor

whi ch

pro-

vides

much

greater

starting

torque

than

previous

cap-

acitor

start

motors. This new

capacitor

start

motor

will

start

the

I/O

under

any

load

conditions

with

normal

line

voltages.

Parts

may

be

ordered

as follows:

Part

No.

1166082

1272458

Desc

ri

pti on

Motor,

115V,

60

Cycle

B/M,

Motor+Mounting

NOTE: This B/M

contains

motor

and

all

hardware

and

a

template

necessary

to

mount

t~e

motor.

20.4

Worn

or

Broken

Be

It

4-26

Drive

belts

may be breaking on

machines

receiving

heavy

usage,

or

machines

over

a

year

old.

The next

time

the

cyc

Ie

shaft

is

removed for

replacement

or

adjustment,

the

motor

belt

should

be

replaced,

re-

gardless

of

its

age

or

condition.

It is

also

recom-

mended

that

an

extra

belt

be

placed

on

the

cycle

shaft

.

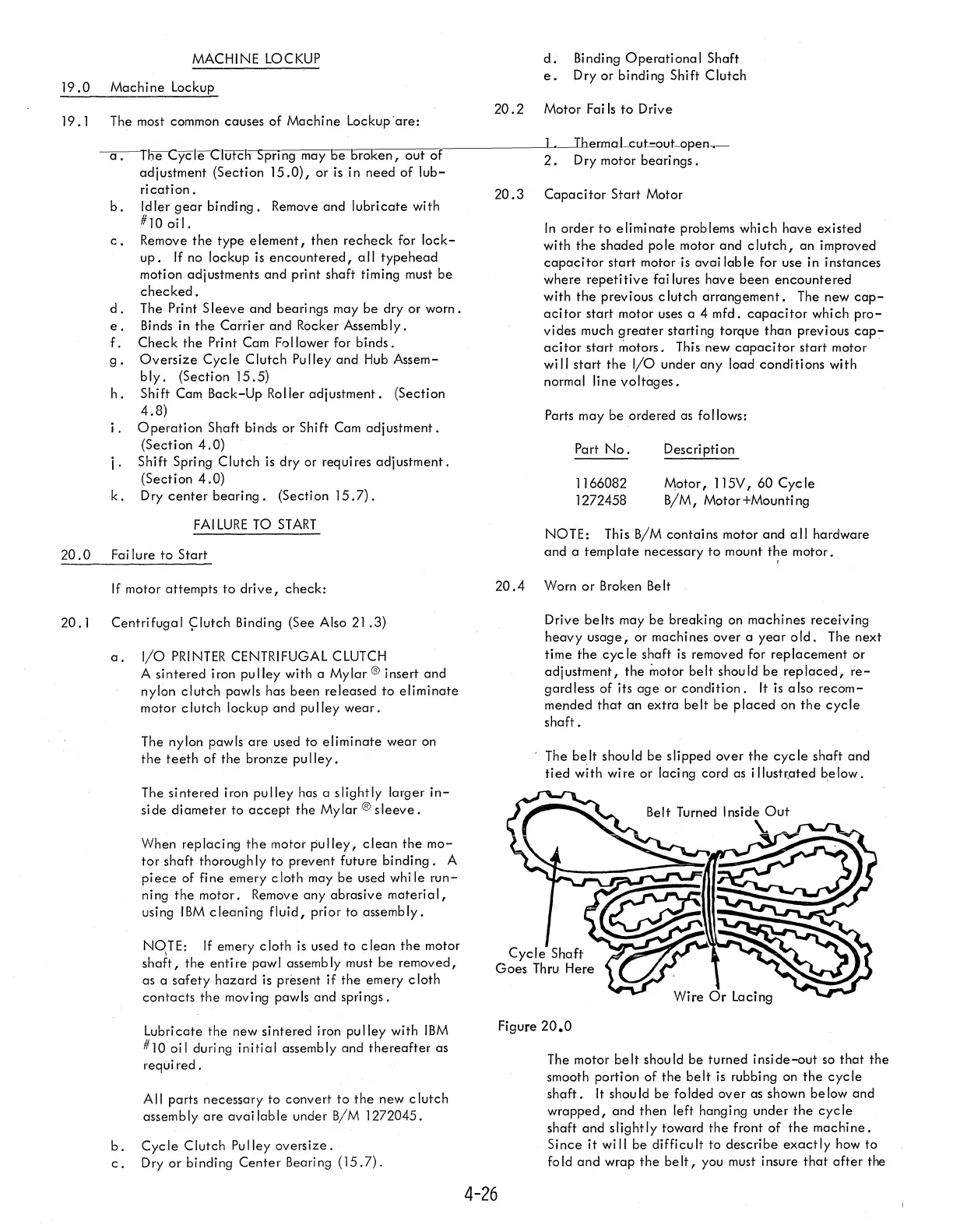

The

be

It

shou

Id

be

slipped

over

the

cyc

Ie

shaft

and

tied

with

wire

or

lacing cord.as illustr.ated

below.

Wire

Or

Lacing

Figure

20.0

The motor

belt

should

be

turned

inside-out

so

that

the

smooth portion

of

the

belt

is

rubbing on

the

cycle

shaft.

It

shou

Id

be fo Ided

over

as shown

be

low

and

wrapped,

and

then

left hanging

under

the

cycle

shaft

and

slightly

toward

the

front

of

the

machine.

Since

it

will

be

difficult

to

describe

exactly

how to

fold

and

wrap

the

belt,

you must insure

that

after

the

Loading...

Loading...