NOTE: The

operational

clutch

ratchet

must be

posi-

tioned

laterally

on

the

operational shaft

so

that

each

clutch

release

arm will

take

an

equal

lateral

bite on its

respective

clutch

wheel.

This insures

that

neither

clutch

release arm

can

slip sideways off its respe.o.tive

clutch

wheel causing an unwanted cam

operation.

This

condi-

tion is most serious on

the

carrier

return/index

cam as it

will cause an index operation to

occur

each

time

the

cam

is

released.

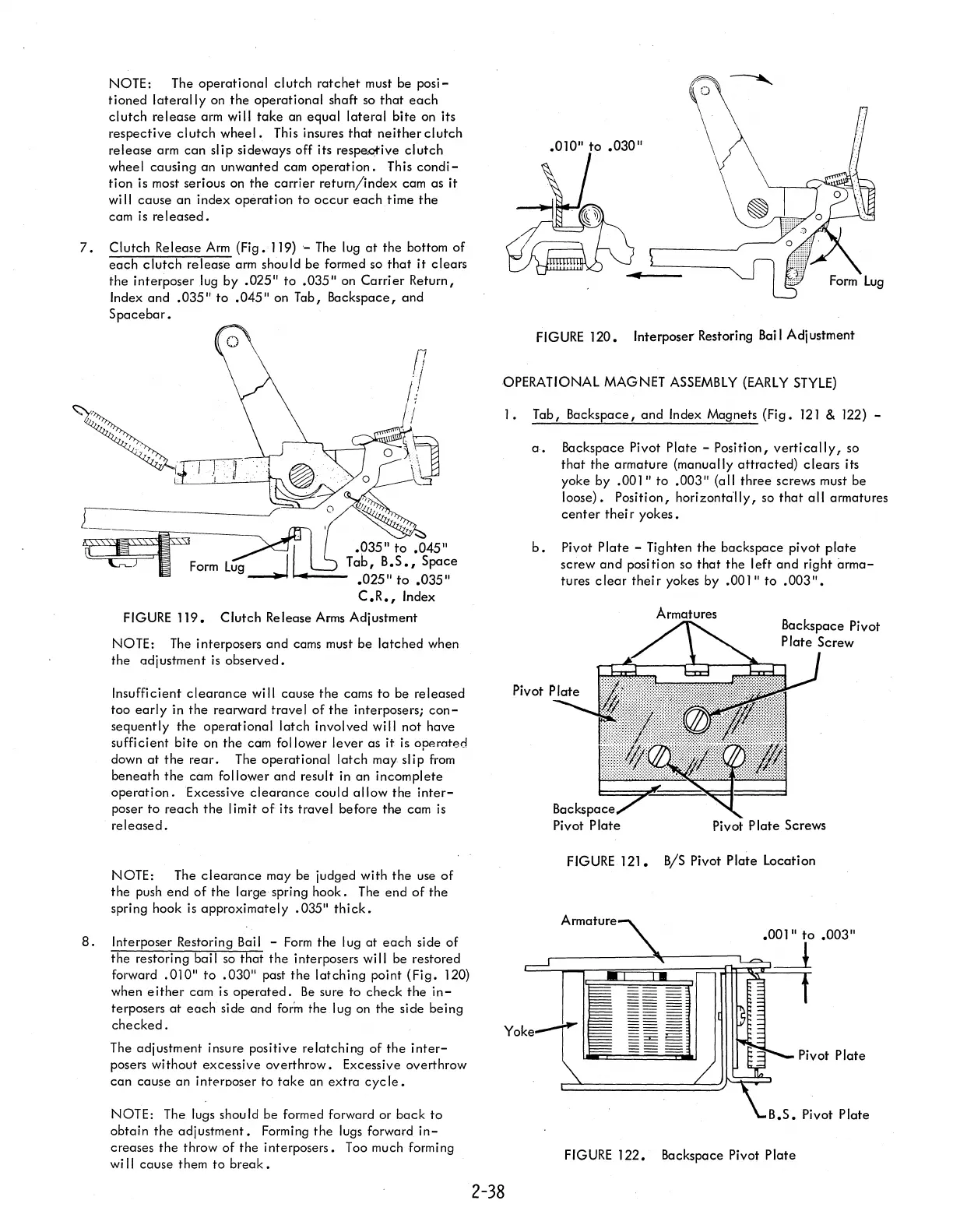

7.

Clutch Release

Arm

(Fig

.119)-

The lug

at

the bottom

of

each

clutch

release

arm should be formed so

that

it

clears

the interposer lug by

.025"

to

.035"

on

Carrier

Return,

Index and

.035"

to

.045"

on Tab, Backspace, and

Spacebar.

C.R.,

Index

FIGURE

119.

Clutch

Release

Arms

Adjustment

NOTE: The interposers

and

cams must be

latched

when

the

adjustment

is

observed.

Insufficient

clearance

wi

II

cause

the

cams

to

be released

too

early

in

the

rearward travel

of

the

interposers;

con-

sequently

the

operational

latch

involved will not have

sufficient bite on

the

cam follower

lever

as

it

is

operated

down

at

the

rear.

The operational

latch

may slip

from

beneath

the

cam follower and result in an incomplete

operation . Excessive

clearance

could

allow

the

inter-

poser

to

reach

the

limit

of

its travel before the cam

is

released.

NOTE: The

clearance

may be judged with

the

use

of

the

push

end

of

the large spring hook. The

end

of

the

spring hook

is

approximately

.035"

thick.

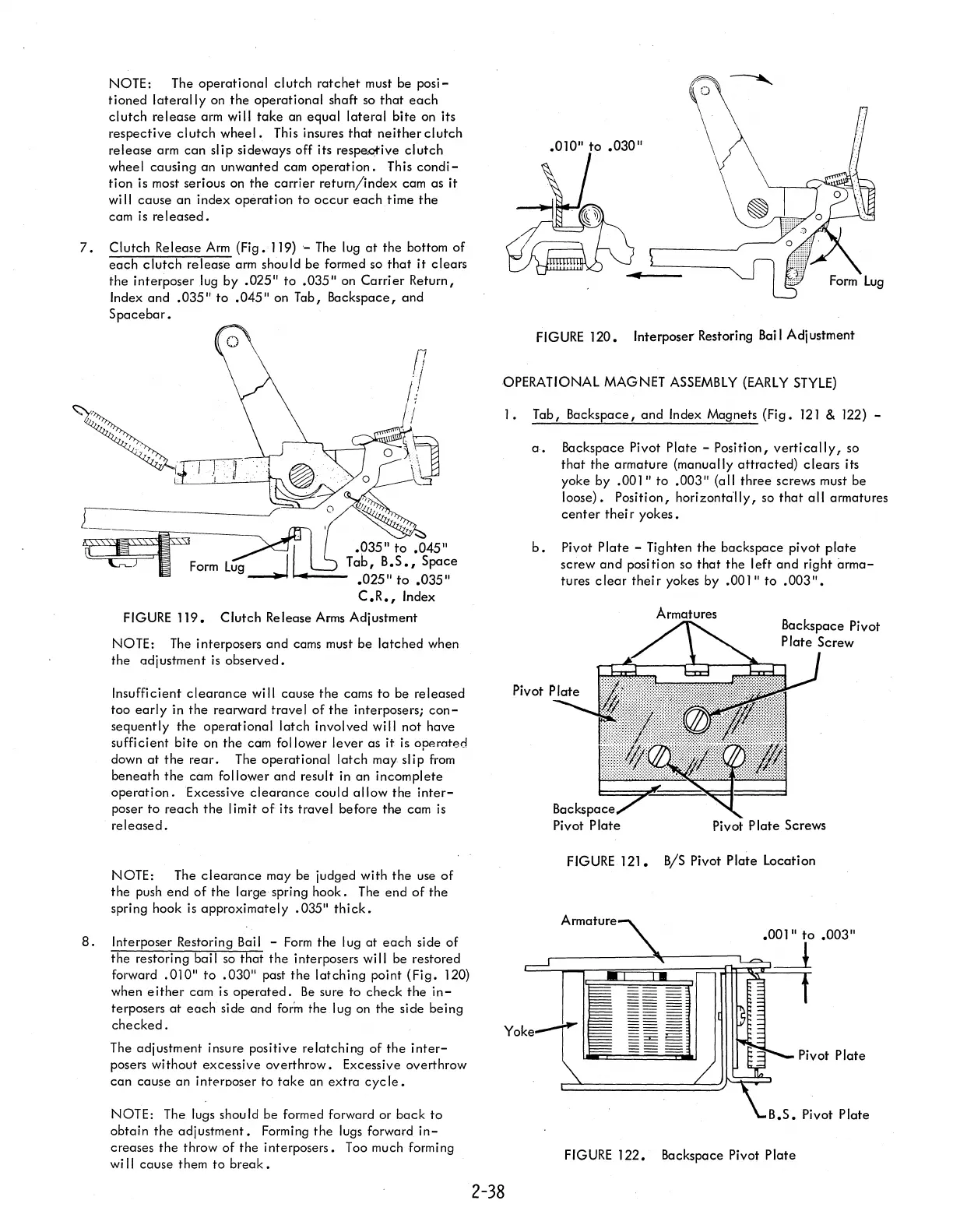

8.

Interposer Restoring Bail -

Form

the lug

at

each

side

of

the

restoring bai I so

that

the

interposers

wi

II

be restored

forward

.010"

to

.030"

past

the

latching

point

(Fig.

120)

when

either

cam is

operated.

Be

sure to

check

the

in-

terposers

at

ea~h

side and

form

the lug on the side being

checked.

The adjustment insure positive relatching

of

the

inter-

posers without excessive overthrow. Excessive overthrow

can

cause an interposer to

take

an

extra

cyc

Ie.

NOTE: The lugs should be formed forward or

back

to

obtain

the

adjustment.

Forming

the

lugs forward

in-

creases

the

throw

of

the

interposers. Too much forming

wi

II

cause them

to

break.

.010"

to

.030"

FIGURE

120.

Interposer Restoring

Bai

I Adjustment

OPERATIONAL MAGNET

ASSEMBLY

(EARLY

STYLE)

2-38

1.

Tab, Backspace,

and

Index Magnets

(Fig.

121

& 122) -

a.

Backspace Pivot Plate - Position,

vertically,

so

that

the

armature {manually attracted}

clears

its

yoke by

.001"

to

.003"

{a

II

three screws must be

loose}. Position,

horizonta"ily, so

that

all

armatures

center

thei r

yokes.

b.

Pivot

Plate

- Tighten

the

backspace pivot

plate

screw

and

position so

that

the

left

and

right

arma-

tures

clear

their

yokes by

.001"

to

.003".

Pivot P

late

Screws

FIGURE

121.

B/S Pivot Plate Location

Armature

FIGURE

122.

Backspace Pivot

Plate

Loading...

Loading...