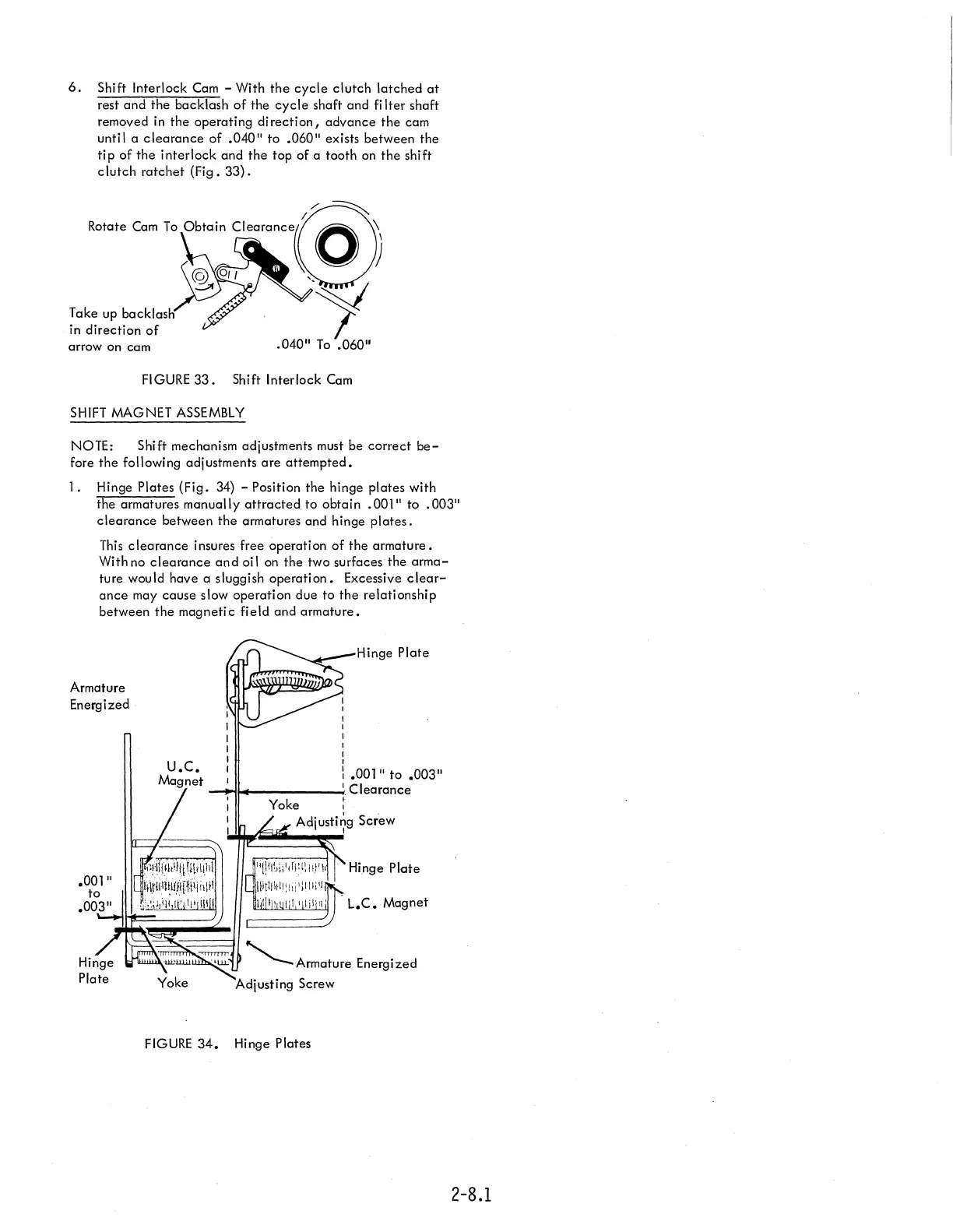

6.

Shift Interlock

Cam

- With

the

cycle

clutch latched

at

rest and the backlash

of

the

cycle

shaft and fi Iter shaft

removed

in

the operating

direction,

advance

the

cam

until a

clearance

of

.040"

to

.060"

exists between the

tip

of the interlock and the top of a tooth

on

the shift

clutch

ratchet (Fig.

33).

Take up backlash

in

direction

of

arrow on cam

FIGURE

33.

Shift Interlock

Cam

SHIFT

MAGNET

ASSEMBLY

NOTE: Shift mechanism adjustments must be correct

be-

fore the following adjustments

are

attempted.

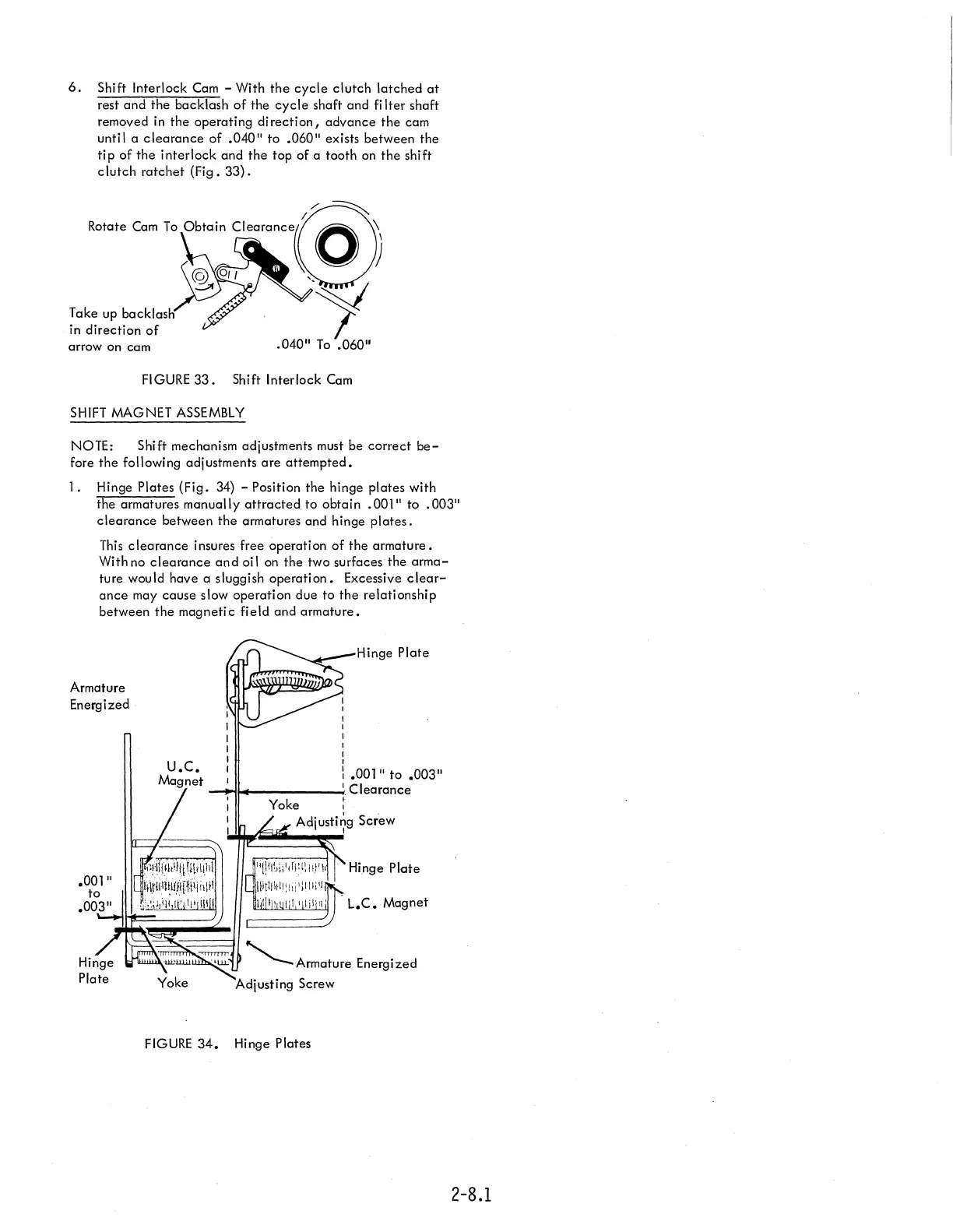

1. Hinge Plates (Fig. 34) - Position the hinge plates with

the armatures manually

attracted

to obtain

.001"

to

.003"

clearance

between

the

armatures and hinge

plates.

This

clearance

insures free operation of the armature.

With no

clearance

and

oil

on

the two surfaces the

arma-

ture would have a sluggish

operation.

Excessive

clear-

ance

may cause slow operation due to the relationship

between the magnetic field and armature.

Armature

Energized

.001"

to

I

I

I

Hinge Plate

:

.001"

to

.003"

-""i~

_____

----I.

Clearance

Yoke

~

Adjusti~g

Screw

iIT=1...:===~

1'~~~1

"!!%1:'dP(!llt'li Hinge Plate

Hltll\tll!tli'lilli'l

.00~3)"

~~~~~~

L.C.

Magnet

"-Armature

Energized

Adjusting

Screw

FIGURE

34.

Hinge Plates

2-8.1

Loading...

Loading...