2.

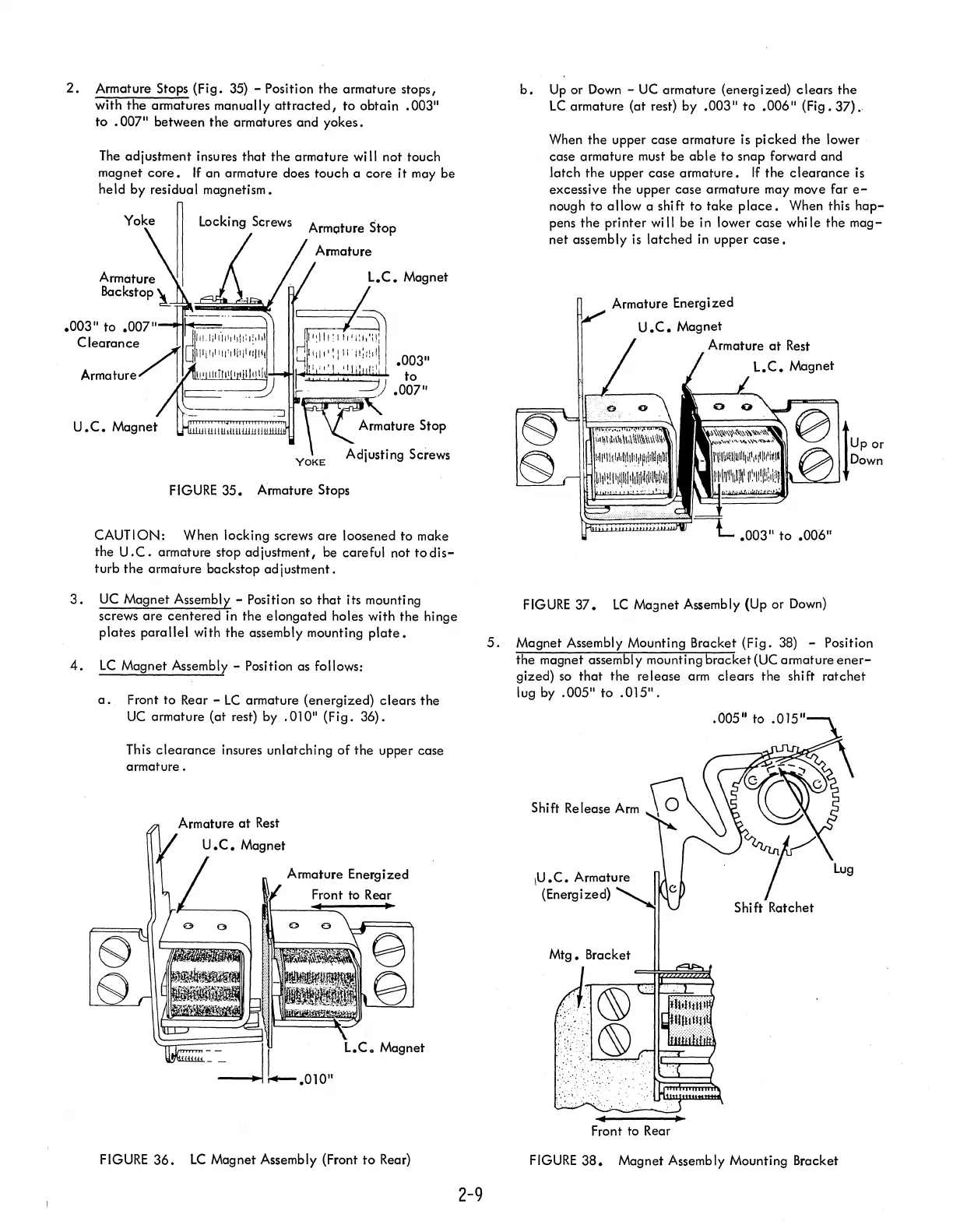

Armature Stops (Fig.

35)

- Position

the

armature stops,

with

the

armatures manually

attracted,

to

obtain .003"

to

.007" between

the

armatures and

yokes.

The

adjustment insures

that

the

armature will not touch

magnet

core.

If

an armature does touch a core

it

may be

held by residual magnetism.

Yoke

~

locking

Screws "

Armoture Stop

Armature

Backstop

~~"~~='iI

FIGURE

35. Armature Stops

CAUTION: When locking screws

are

loosened

to

make

the

U.C.

armature stop adjustment, be careful not

todis-

turb

the

armature backstop adjustment.

3.

UC

Magnet Assembly - Position so

that

its mounting

screws

are

centered

in the

elongated

holes with

the

hinge

plates

parallel

with the assembly mounting

plate.

4.

LC

Magnet Assembly - Position as follows:

a.

Front to Rear -

LC

armature (energized)

clears

the

UC

armature (at rest) by

.010"

(Fig.

36).

This

clearance

insures unlatching

of

the

upper case

armature.

Armature Energized

FIGURE

36.

LC

Magnet Assembly (Front

to

Rear)

2-9

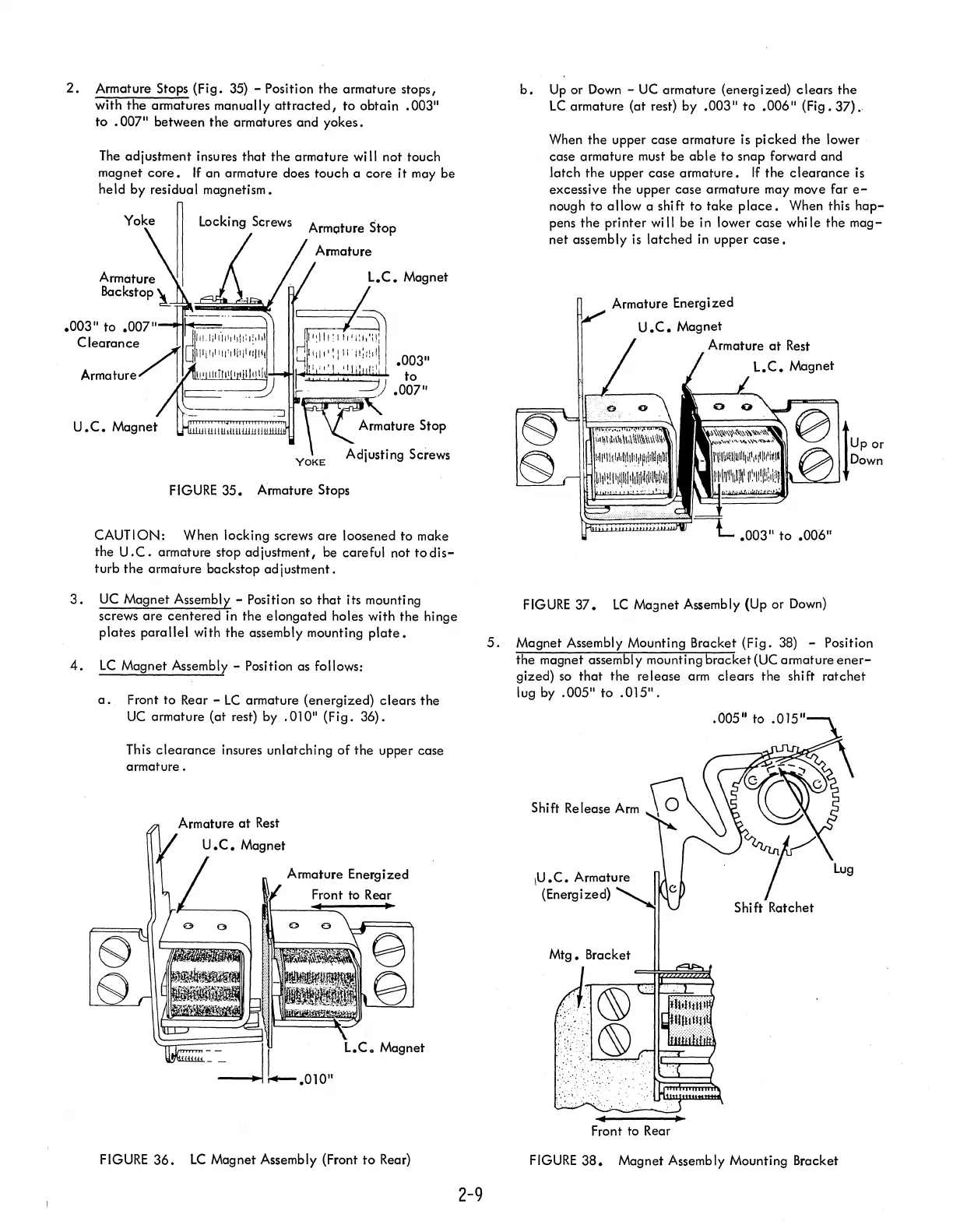

b.

Up

or

Down

-

UC

armature (energized)

clears

the

LC

armature (at rest) by .003"

to

.006" (Fig. 37)."

When

the

upper case armature is

picked

the lower

case armature must be

able

to

snap forward and

latch

the

upper case

armature.

If

the

clearance

is

excessive

the

upper case armature may move far

e-

nough

to

allow

a shift

to

take

place.

When this

hap-

pens

the

printer

wi

II

be in lower

case

whi Ie

the

mag-

net

assembly

is

latched in upper

case.

Armature Energized

U.C.

Magnet

Armature

at

Rest

.003"

to

.006"

FIGURE

37.

LC

Magnet Assembly (Up or

Down)

5.

Magnet Assembly Mounting Bracket

(Fig.

38) - Position

the

magnet assembl y mounting

bracket

(UC armature

ener-

gized)

so

that

the

release arm

clears

the

shift

ratchet

lug by .005"

to

.015".

Shift Release

Arm

\U.C.

Armature

(Energized)

Mtg.

Bracket

FIGURE

38.

Magnet Assembly Mounting Bracket

Loading...

Loading...