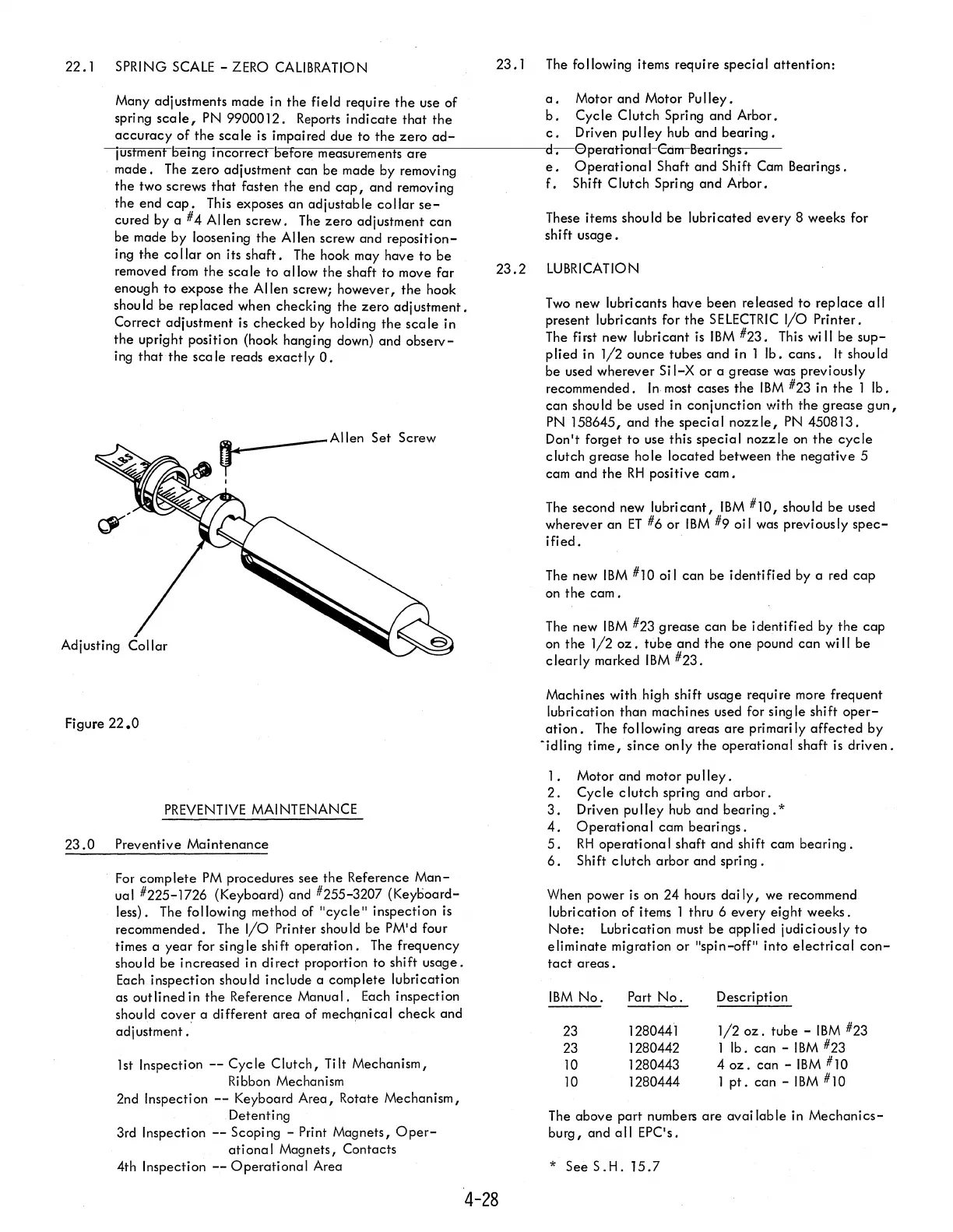

22.1

SPRING

SCALE

- ZERO CALIBRATION

Many adjustments made in

the

field require

the

use of

spring

scale,

PN

9900012.

Reports

indicate

that

the

accuracy

of

the

scale

is impaired due

to

the

zero

ad-

lustment

celng

I

ncorrect

before measurements

are

made.

The

zero

adjustment can be made by removing

the

two screws

that

fasten

the

end

cap,

and

removing

the

end

cap.

This exposes

an

adjustable

collar

se-

cured by a

#4

Allen

screw.

The

zero

adjustment

can

be made by loosening

the

Allen screw and

reposition-

ing

the

collar

on its

shaft.

The hook may have

to

be

removed

from

the

scale

to

allow

the

shaft to move far

enough

to

expose

the

Allen screw; however,

the

hook

should

be

replaced

when checking

the

zero

adjustment.

Correct adjustment is

checked

by holding

the

scale

in

the

upright position (hook hanging down) and

observ-

ing

that

the

scale

reads

exactly

o.

~

______

Allen Set Screw

Figure

22.0

PREVENTIVE

MAINTENANCE

23.0

Preventive

Maintenance

For

complete

PM

procedures see

the

Reference

Man-

ual #225-1726 (Keyboard) and #255-3207

(Keyooard-

less). The following method of

"cycle"

inspection

is

recommended. The

I/O

Printer should

be

PM'd four

times a

year

for sing

Ie

shift

operation.

The frequency

should

be

increased in

direct

proportion to shift

usage.

Each inspection should

include

a complete lubrication

as

outlined

in

the

Reference

Manual.

Each inspection

should

cover

a

different

area

of

mech~riical

check

and

adjustment.

1st Inspection

--

Cyc

Ie

Clutch,

Ti

It

Mechanism,

Ribbon Mechanism

2nd Inspection

--

Keyboard

Area,

Rotate Mechanism,

Detenting

3rd Inspection

--

Scoping - Print Magnets,

Oper-

ational

Magnets, Contacts

4th Inspection

--

Operational

Area

23.1

The following items require

special

attention:

a • Motor

and

Motor

Pu

Iley •

b.

Cycle

Clutch

Spring and Arbor.

c.

Driven

pulley

hub and

bearing.

d • 0peratfontrl-EtirrrB-earmgs.

e.

Operational

Shaft

and

Shift

Cam

Bearings.

f.

Shift Clutch Spring

and

Arbor.

These items should

be

lubricated

every

8 weeks for

shift

usage.

23.2

LUBRICATION

Two

new lubri

cants

have

been

re leased

to

rep

lace

a

II

present lubricants for

the

SELECTRIC

I/O

Printer.

The first new lubricant

is

IBM

#23.

This

wi

II

be

sup-

plied in

1/2

ounce

tubes

and

in 1

lb.

cans.

It

should

be used

wherever

Si

I-X

or

a

grease

was previously

recommended.

In

most cases

the

IBM

#23 in

the

1

lb.

can

should

be

used in

conjunction

with

the

grease

gun,

PN 158645, and

the

speci a I nozz

Ie,

PN

450813.

Don't forget

to

use this

special

nozzle

on

the

cycle

clutch

grease

hole

located

between

the

negative

5

cam

and

the

RH

positive

cam.

The second new

lubricant,

IBM

#10,

should

be

used

wherever

an

ET

#6 or

IBM

#9 oi I was previously

spec-

ified.

The new

IBM

#10 oi I

can

be

identified

by a red

cap

on

the

cam.

The new

IBM

#23

grease

can

be

identified

by

the

cap

on

the

1/2

oz.

tube

and

the

one pound

can

wi

II

be

clearly

marked

IBM

#23.

Machines with high shift usage require more frequent

lubrication than machines used for sing

Ie

shift

oper-

ation.

The following

areas

are

primarily

affected

by

-idling

time,

since

only

the

operational

shaft is

driven.

1.

Motor and motor

pu

Iley .

2.

Cycle

clutch

spring and

arbor.

3.

Driven pu lIey hub and

bearing.

*

4.

Operati

ona I cam beari ngs .

5.

RH

operational

shaft and shift cam

bearing.

6.

Shift

clutch

arbor

and

spring.

When power

is

on

24

hours dai Iy, we recommend

lubrication

of

items 1 thru 6

every

eight

weeks.

Note:

Lubrication must

be

applied

judiciously

to

eliminate

migration

or

"spin-off" into

electrical

con-

tact

areas.

IBM

No.

Part

No.

Descripti on

23

1280441

1/2

oz.

tube -

IBM

#23

23 1280442

1

lb.

can

-

IBM

#23

10

1280443

4

oz.

can

-

IBM

#10

10

1280444

1

pt.

can

-

IBM

# 1 0

The

above

part numbers

are

avai

lable in

Mechanics-

burg, and

all

EPC's.

*

See

S.H.

15.7

4-28

Loading...

Loading...