Since this .260" to .270"

is

measured between

the

typehead

and the platen it

is

not a measurement of

the

powered travel

of

the

typehead.

The

.020" to

.030" free flight

is

included in this .260"

to

.270"

and must

be

subtracted in order

to

determine the

amount of powered

travel.

The

powered travel must

never

exceed

.265" as this will

cause

typehead

breakage.

The base of

the

Hooverometer handle can be used

as a measuring devi

ce

as illustrated in Fig.

95.

The

handle base

is

about .250" thick; however

they

do

not

all

measure the

same.

Each handle should be

measured with"a dial

indicator

or micrometer to

de-

termine its

exact

size.

When the

size

of the handle

base

is

determined,

a thickness of

tab

cards should

be

placed

around

the

platen

that will total .260"

to

.270" when added

to

the thickness of

the

handle

base.

e.

Both adjustments must be rechecked

and

refined

un-

ti I these conditions

are

obtained.

Be

sure

to

tighten

both screws firmly when

the

adjustments

are

com-

pleted.

NOTE:

The

adjustments should be checked with

the

ri

bbon removed.

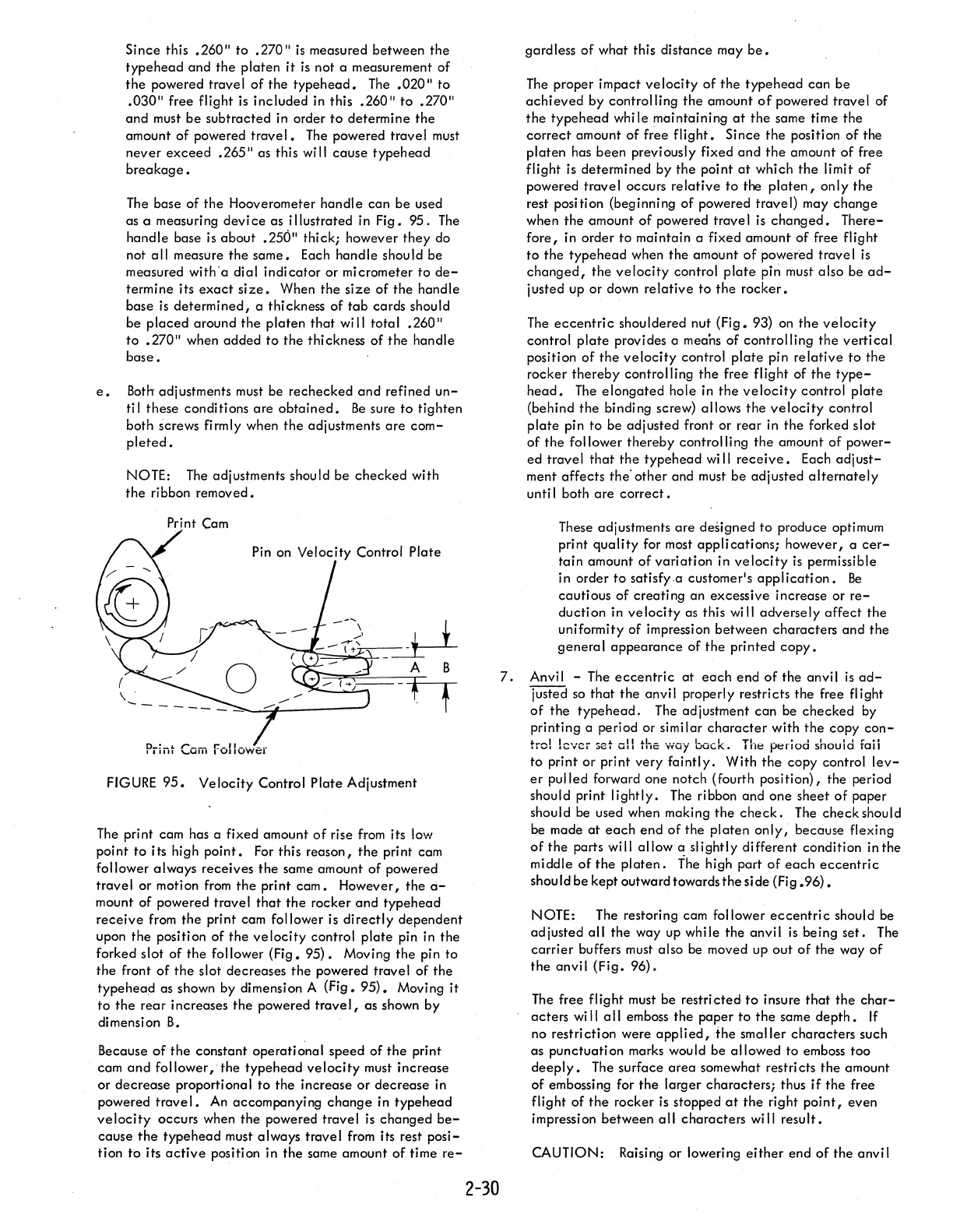

Print

Cam

Piint

Com

follower

FIGURE

95.

Velocity Control Plate Adjustment

The

print cam has a fixed amount

of

rise

from

its low

point to its high

point.

For

this reason,

the

print cam

follower always receives the same amount of powered

travel or motion

from

the

print

cam.

However, the

a-

mount of powered travel

that

the

rocker

and

typehead

receive

from

the

print cam follower is

directly

dependent

upon the position of the

velocity

control

plate

pin in the

forked slot of the follower (Fig.

95).

Moving the pin to

the

front

of

the

slot decreases

the

powered travel of the

type

head as shown by dimension A (Fig.

95).

Moving

it

to

the

rear increases

the

powered trave

I,

as shown by

di

mensi on

B.

Because

of

the

constant operational speed of

the

print

cam

and

follower, the typehead

velocity

must increase

or

decrease

proportional to

the

increase

or

decrease in

powered

travel.

An

accompanying

change

in typehead

velocity

occurs when the powered travel

is

changed

be-

cause

the

type head must always trave I

from

its rest

posi-

tion

to

its

active

position in

the

same amount of time

re-

2-30

gardless of what this distance may

be.

The

proper impact

velocity

of

the

typehead

can be

achieved

by controlling

the

amount

of

powered travel of

the

typehead

while maintaining

at

the same time the

correct

amount of free

flight.

Since the position of the

platen

has been previously fixed

and

the

amount

of

free

flight

is

determined

by

the

point

at

which

the

limit of

powered travel occurs

relative

to the

platen,

on

Iy

the

rest position (beginning of powered travel) may change

wheA

the amount of powered trave I

is

changed.

There-

fore,

in order to maintain a fixed amount of free flight

to

the type head when the amount

of

powered travel

is

changed,

the

velocity

control

plate

pin must also be

ad-

justed up or down

relative

to

the

rocker.

The

eccentric

shouldered nut (Fig. 93)

on

the

velocity

control

plate

provides a means of controlling

the

vertical

position of

the

velocity

control

plate

pin

relative

to

the

rocker thereby

controlling

the

free flight of

the

type-

head.

The

elongated

hole in

the

velocity

control

plate

(behind

the

binding screw) allows

the

velocity

control

plate

pin to be adjusted front or rear in

the

forked slot

of the

follower thereby controlling

the

amount of power-

ed travel

that

the

typehead

wi

II

receive.

Each adj

ust-

ment affects the· other and must

be

adjusted

alternately

unti I both

are

correct.

These adjustments

are

designed to produce optimum

pri nt qua

Ii

ty

for

most

app

Ii cati ons; however, a

cer-

tain amount

of

variation in

velocity

is

permissible

in order

to

satisfy"a customer's

application.

Be

cautious of creating an excessive increase or

re-

duction in

velocity

as this will adversely

affect

the

uniformity of impression between characters and

the

genera I

appearance

of

the

printed

copy.

7.

Anvil - The

eccentric

at

each

end

of

the anvil

is

ad-

justed

so

that the anvil properly restricts the free flight

of

the

typehead.

The

adjustment can be checked by

printing a period or similar

character

with

the

copy

con-

trel

lever

set

all

the way

back.

The

period shouid

raii

to print or print very

faintly.

With

the

copy control

lev-

er

pulled forward one notch (fourth position), the period

should print

lightly.

The

ribbon and one sheet of paper

should be used when making

the

check.

The

check should

be made

at

each

end

of

the platen

only;

because flexing

of

the

parts will allow a slightly different condition

inthe

middle

of

the

platen.

The

high part

of

each

eccentric

should be kept outward towards

the

side (Fig

.96).

NOTE:

The

restoring cam follower

eccentric

should be

adjusted

all

the way up while the anvil

is

being

set.

The

carrier

buffers must also be moved up

out

of

the way

of

the anvil (Fig.

96).

The

free flight must be

restricted

to

insure

that

the

char-

acters

wi

II

a

II

emboss the paper

to

the

same

depth.

If

no restriction were

applied,

the

smaller characters such

as punctuation marks would be allowed to emboss too

deeply.

The surface

area

somewhat restri cts

the

amount

of embossing for the larger characters; thus

if

the free

flight of

the

rocker is stopped

at

the

right

point,

even

impression between

all

characters will result.

CAUTION: Raising or lowering

either

end

of

the anvil

Loading...

Loading...