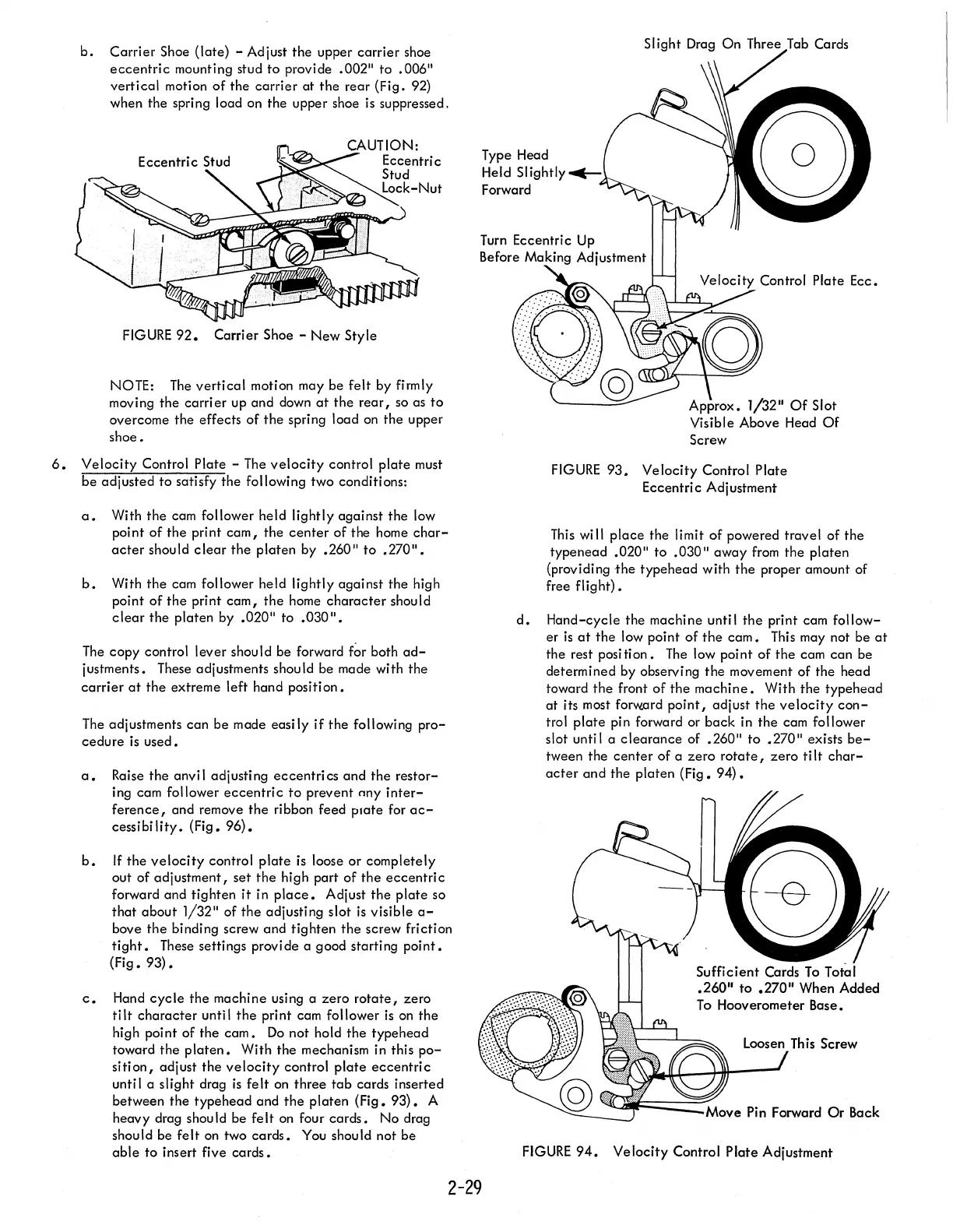

b.

Carrier

Shoe (late) - Adjust

the

upper

carrier

shoe

eccentric

mounting stud

to

provide .002"

to

.006"

vertical

motion

of

the

carrier

at

the

rear (Fig. 92)

when the spring load on the upper shoe is suppressed.

CAUTION:

FIGURE

92.

Carrier Shoe - New Style

Eccentric

Stud

Lock-Nut

NOTE:

The

vertical

motion may be

felt

by firmly

moving the

carrier

up and down

at

the

rear,

so as

to

overcome the effects

of

the

spring load

on

the upper

shoe.

6.

Velocity

Control Plate - The

velocity

control

plate

must

be

adjusted

to

satisfy the following two conditions:

a.

With

the

cam follower held lightly against the low

point of the print

cam,

the

center

of the home

char-

acter

should

clear

the

platen

by .260"

to

.270".

b.

With

the

cam follower held lightly against the high

point

of

the

print

cam,

the

home

character

should

clear

the

platen by .020" to

.030".

The

copy control lever should be forward

f~r

both

ad-

justments. These adjustments shou

Id

be made with

the

carrier

at

the

extreme left hand position.

The adjustments

can

be made easily

if

the

following

pro-

cedure

is

used.

a.

Raise the anvil adjusting

eccentrics

and the restor-

ing cam follower

eccentric

to

prevent nny

inter-

ference,

and remove

the

ribbon feed

plate

for

ac-

cessibility.

(Fig. 96).

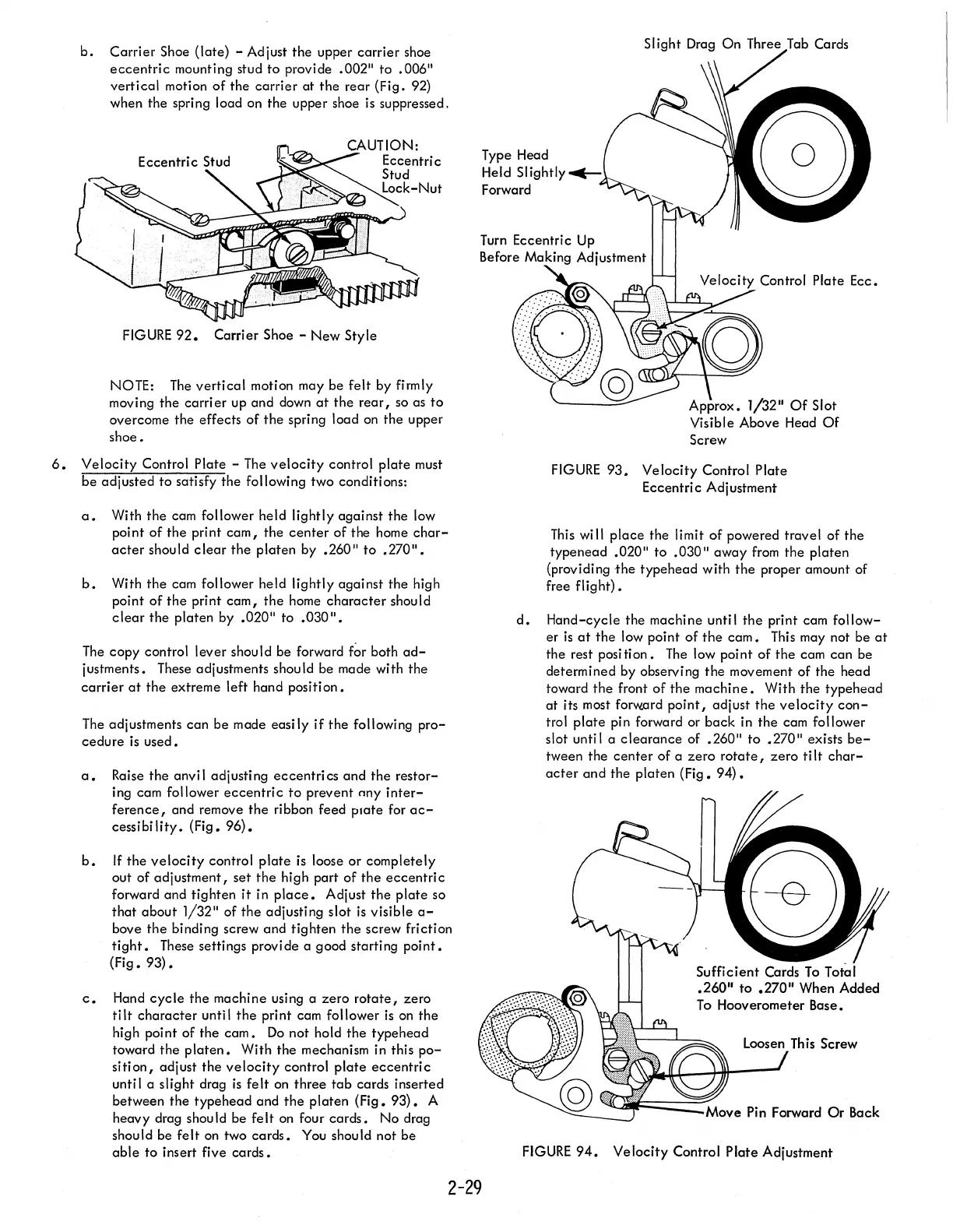

b.

If

the

velocity

control

plate

is

loose or completely

out of adjustment,

set

the

high part of

the

eccentric

forward and tighten

it

in

place.

Adjust

the

plate

so

that

about

1/32" of

the

adjusting slot

is

visible

a-

bove

the

binding screw and tighten

the

screw friction

tight.

These settings provi de a good starting

point.

(Fig.

93).

c.

Hand

cycle

the machine using a zero

rotate,

zero

tilt

character

until

the

print cam follower

is

on

the

high point of the

cam.

Do

not hold

the

typehead

toward the

platen.

With the mechanism in this

po-

sition,

adjust

the

velocity

control

plate

eccentric

until a slight drag

is

felt

on

three

tab

cards inserted

between the typehead and

the

platen (Fig.

93).

A

heavy drag should be

felt

on

four

cards.

No

drag

should be

felt

on

two

cards.

You

should not be

able

to

insert five

cards.

2-29

Type Head

Held

Slightly

Forward

Screw

Control

Plate Ecc.

FIGURE

93.

Velocity

Control Plate

Eccentric Adjustment

This

will

place

the limit of powered travel of the

typenead .020"

to

.030"

away

from

the platen

(providing

the

typehead with

the

proper amount of

free

flight).

d.

Hand-cycle the machine until

the

print cam

follow-

er

is

at

the

low point

of

the

cam.

This

may not be

at

the rest position.

The

low point of the cam

can

be

determined by observing

the

movement of the head

toward

the

front of

the

machine.

With

the

type head

at

its most forward

point,

adjust

the

velocity

con-

trol

plate

pin forward or

back

in the cam follower

slot until a

clearance

of .260"

to

.270" exists

be-

tween the

center

of a

zero

rotate,

zero

tilt

char-

acter

and

the

platen

(Fig.

94).

-_-J

=:::==:::::::~AO\,e

Pin Forward

Or

Back

FIGURE

94.

Velocity

Control Plate Adjustment

Loading...

Loading...