If

the

bracket

were adjusted too low, the steps

woll

Id

be

at

an

angle

to

the

line

of

motion

of

the

cycle

clutch

latch.

The

latch

would have difficulty in moving

for-

ward

to

release the

clutch

sleeve,

and

a slow, hesitant

operation would

result.

With

the

bracket

too

high,

the

force

of

stopping

the

cycle

shaft through

the

cycle

clutch

sleeve would

tend

to cam

the

latch

forward. A

repeat

cyc

Ie

operati

on

could

result.

When properly adjusted the

top

of

the

latch pivot pin is

1.546"

below

the

top

of

the

print

shaft.

This

distance

can be measured

wi

th

the

use

of

the

Hooverometer.

Wi

th

the

head

of

the

Hooverometer

set

at

the

#3

scribe

line,

the head should rest

on

top

of

the

print shaft with

tl-e

handle touching

the

latch pivot pin (Fig.

41).

Be

sure

the

Hooverometer handle is

vertical.

It

will be

vertical

if

the

base

of

the

handle

is

centered

over

the

latch pivot

pin.

NOTE: Changing

the

height

of

the

cycle

clutch

latch

necessitates a readjustment

of

the

cycle

clutch

collar,

cycle

clutch

stop,

and

the

cycle

clutch latch restoring

mechanism.

CA.UTION:

The

latch

bracket

must not become cocked

so

that

only a corner

of

the

latch

plate

is

stopping

the

sleeve.

Excessive

wear

could

result.

The

cycle

clutch

sleeve

could also be

tilted

by

the

latch causing

it

to

bear

against

the

cycle

clutch

pulley hub creating a

noisy

operation.

3.

Cycle

Clutch Spring and

Collar

Adjustments (Early)

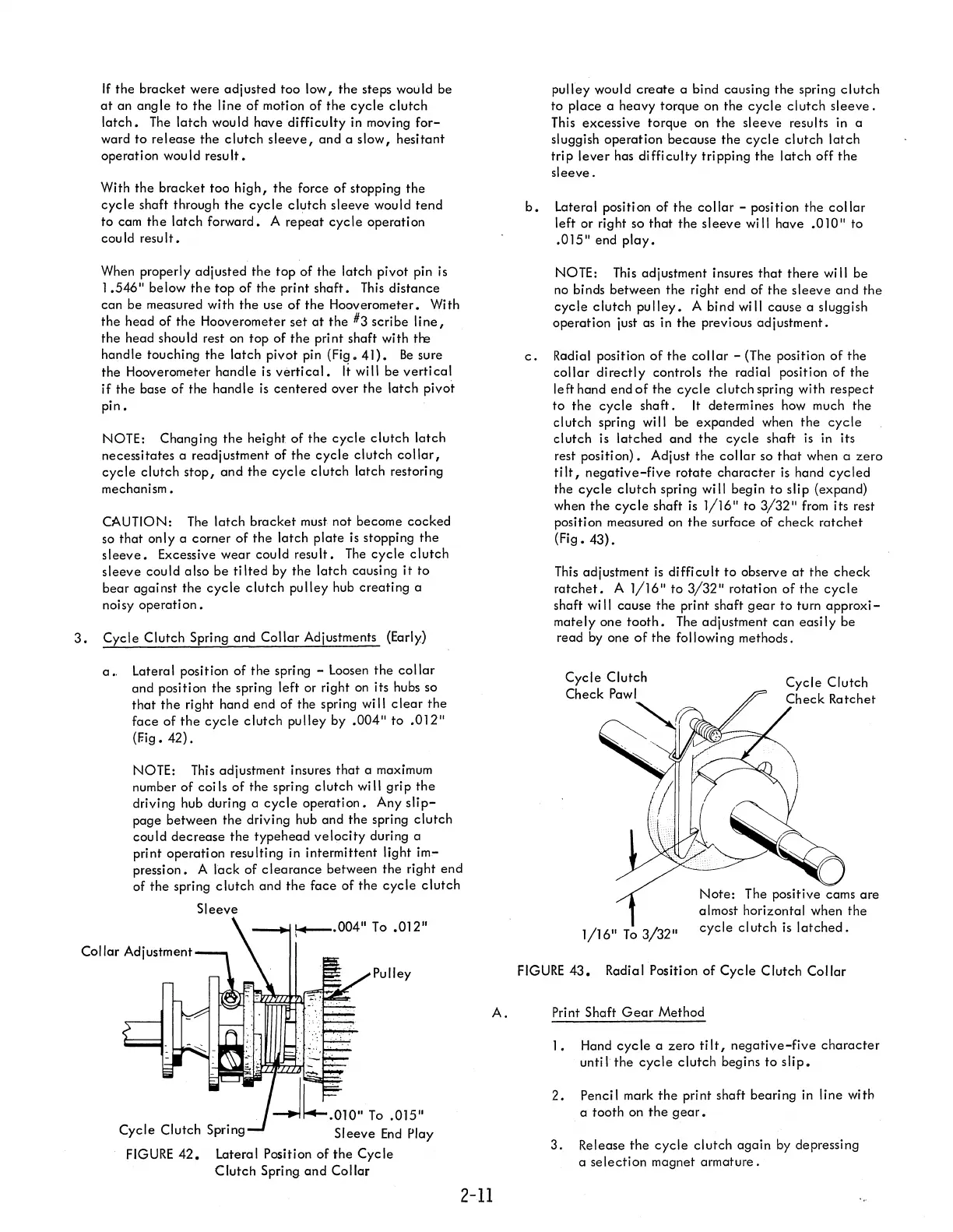

a., Lateral position

of

the

spring - Loosen

the

collar

and position

the

spring left or right

on

its hubs so

that

the

right hand end

of

the spring

wi

II

clear

the

face

of

the

cycle

clutch

pulley by

.004"

to

.012"

(F.ig.

42).

NOTE:

This

adjustment insures

that

a maximum

number

of

coils

of

the

spring clutch

wi

II

grip

the

driving hub during a

cycle

operation.

Any

slip-

page between

the

driving hub and

the

spring

clutch

could

decrease

the

typehead

velocity

during a

print operation resulting in intermittent

light

im-

pression. A

lack

of

clearance

between

the

right

end

of

the

spring

clutch

and

the

face

of

the

cycle

clutch

Sleeve

Collar Adjustment

Pulley

Cycle

Clutch Spring

Sleeve

End

Play

FIGURE

42.

Lateral Position

of

the

Cycle

Clutch

Spring

and

Collar

pulley

would

create

a bind causing

the

spring

clutch

to place a heavy torque on the

cycle

clutch

sleeve.

This excessive torque on the sleeve results in a

sluggish

operation

because

the

cycle

clutch

latch

trip

lever

has difficulty tripping

the

latch

off

the

sleeve.

b.

Lateral position

of

the

collar

- position

the

collar

left or right so

that

the

sleeve

will have

.010"

to

.015"

end

play.

NOTE:

This

adjustment insures

that

there will be

no

binds between

the

right end

of

the

sleeve

and

the

cycle

clutch

pulley.

A bind will cause a sluggish

operation just

as

in

the

previous adjustment.

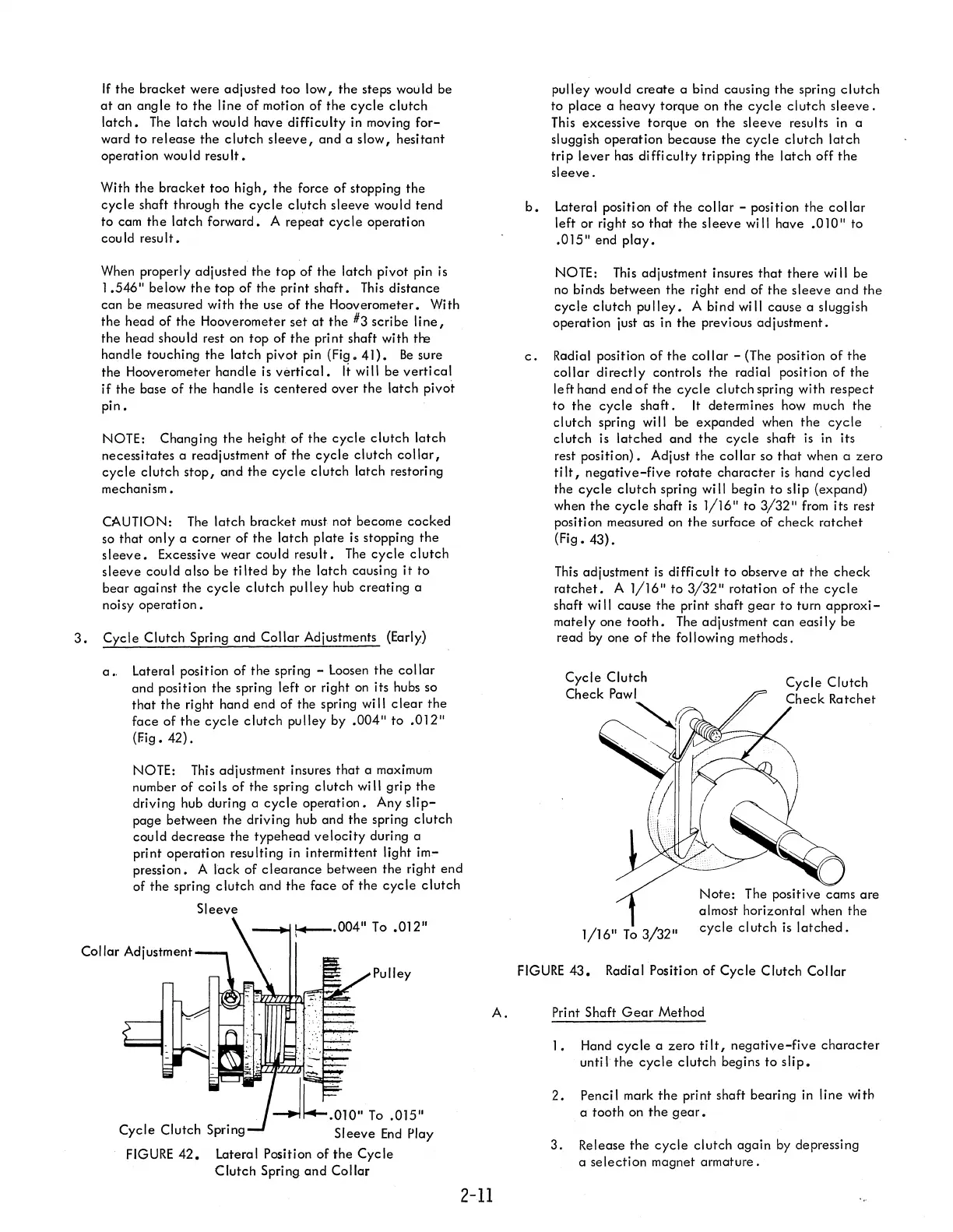

c.

Radial position

of

the

collar

- (The position

of

the

collar

directly

controls

the

radial position

of

the

left hand end

of

the

cycle

clutch spring with respect

to

the

cycle

shaft.

It

determines how much the

clutch spring

wi

II

be expanded when

the

cycle

clutch is

latched

and

the

cycle

shaft

is

in its

rest position). Adjust

the

collar

so

that

when a

zero

ti

It,

negative-five

rotate

character

is

hand

cycled

the

cycle

clutch

spring will begin

to

slip (expand)

when

the

cycle

shaft is

1/16"

to

3/32"

from

its rest

position measured on

the

surface

of

check

ratchet

(Fig. 43).

This

adjustment

is

difficult

to

observe

at

the

check

ratchet.

A

1/16"

to

3/32"

rotation

of

the

cycle

shaft

wi

II

cause

the

print shaft

gear

to

turn

approxi-

matey

one

tooth.

The

adjustment

can

easi ly be

read

by

one

of

the foil owi

ng

methods.

Cycle

Clutch

Check

Ratchet

Note:

The positive cams

are

almost horizontal when

the

1/16"

To

3/32"

cycle

cl utch

is

latched.

FIGURE

43.

Radial Position

of

Cycle

Clutch

Collar

A.

Pri

nt Shaft

Gear

Method

1. Hand

cycle

a

zero

ti

It,

negative-five

character

until

the

cycle

clutch

begins to

slip.

2.

Pencil mark

the

print shaft bearing in line with

a tooth on

the

gear.

3.

Release

the

cycle

clutch

again

by

depressing

a

selection

magnet armature.

2-11

Loading...

Loading...