4.

Slowly hand

cycle

the

machine until

the

check

pawl just drops into a tooth on the

check

rat-

chet.

The print shaft gear should have

rotated

1/2

to one

tooth.

If the print shaft

gear

rotat-

ed

further than one tooth

the

collar

must be

moved top toward

the

rear.

Less

than

1/2

to

one

tooth,

move

it

top

toward

the

front.

A

zero

ti

It,

negative-f

ive rotate

character

is used

because

it

offers

the

greatest

resistance to

the

cycle

shaft during

the

restoring portion

of

a

cycle,

caus-

ing

the

cycle

clutch

spring to slip

at

the

earliest

possible

time.

.

NOTE:

If

the

collar

shouid become completely

loose, a good starting point may be obtained by

positioning

the

collar

so

that

its adjusting screw head

is

approximately in line with the high point

of

the

negative-five

cam.

CAUTION:

The

cycle

clutch stop

attached

to

the

collar

may prevent

the

shaft

from

reaching

the

latched

position.

Any change in the

cycle

clutch

collar

adjustment

wi

II

necessitate a readjustment

of

the stop; the refore

it

is

usually best to loosen

the

stop before attempti

ng

to

adjust the

collar.

B.

Degree Wheel Method

With the machine

at

zero

degrees

(cycle

clutch

latched

at

rest)

select,a

-5

rotate,

0

tilt

character

and hand

cycle

the

machine slowly. The

cycle

clutch

spring should slip and stop driving

at

170

to

175

degrees.

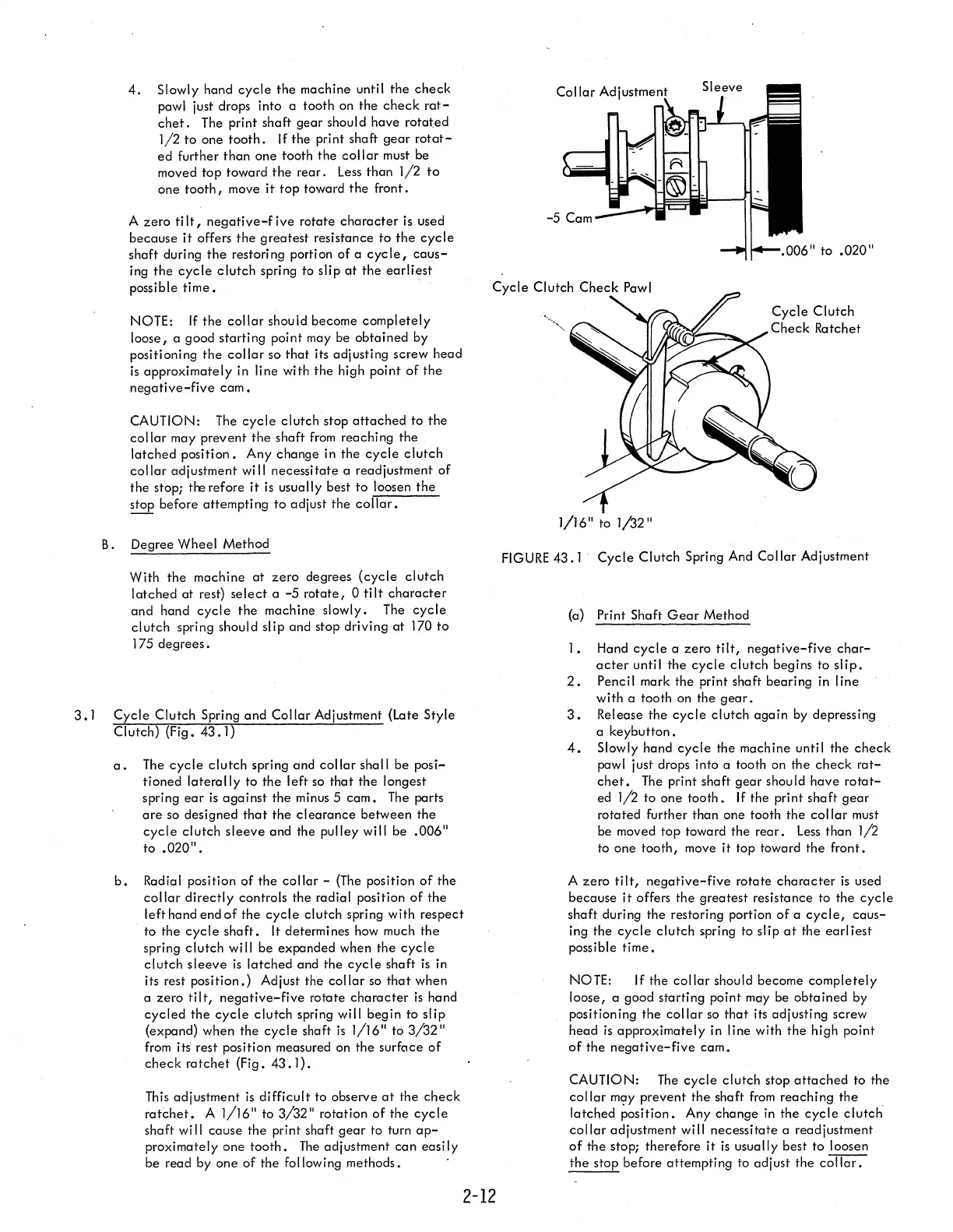

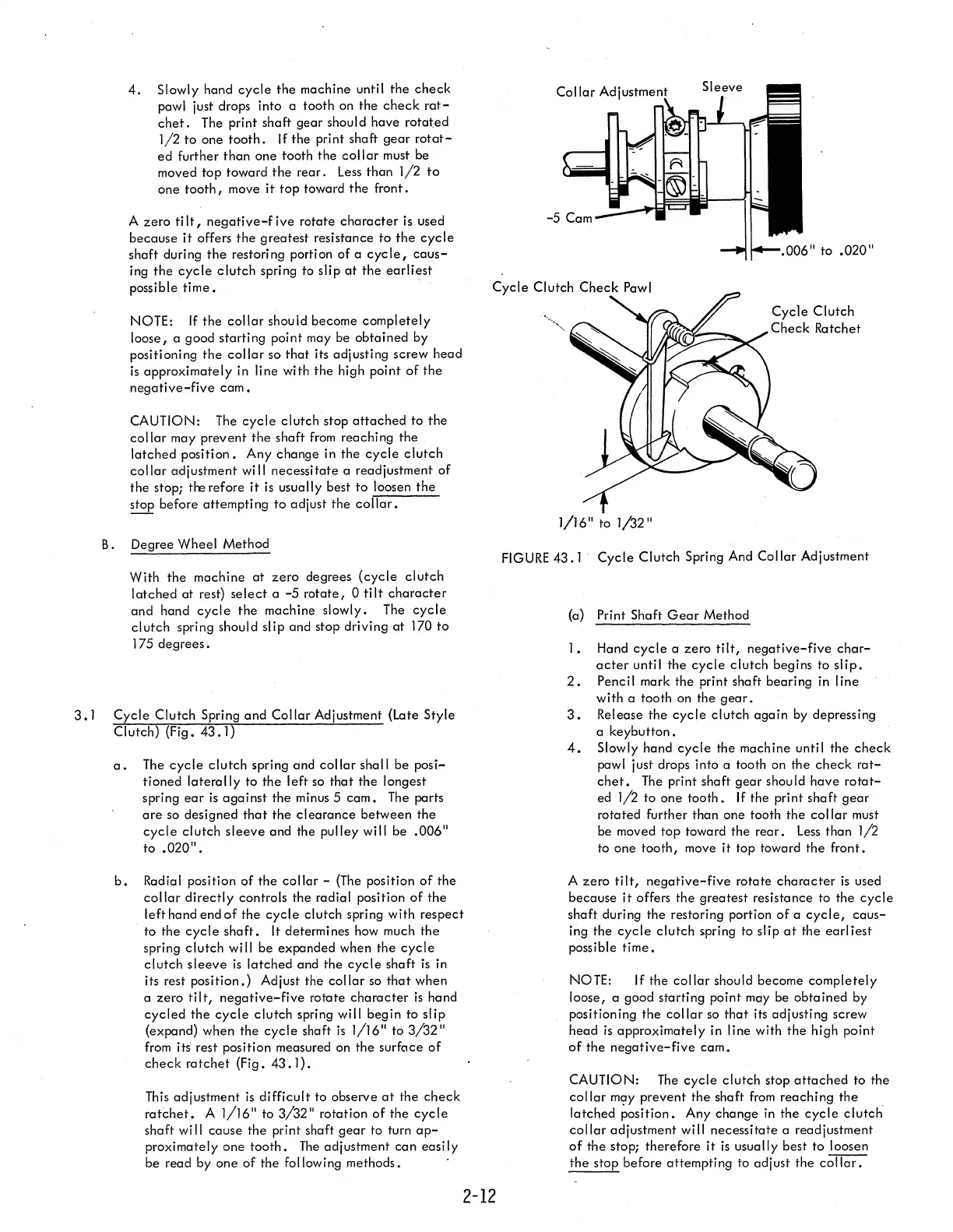

3.1

Cycle

Clutch Spring

and

Collar

Adjustment (Late Style

Clutch) (Fig.

43.1)

a.

The

cycle

clutch

spring and

collar

shall be posi-

tioned

laterally

to the left

so

that

the longest

spring

ear

is

against

the minus 5

cam.

The perts

are

so designed

that

the

clearance

between the

cycle

clutch

sleeve

and the pulley will be .006"

to

.020".

b.

Radial position

of

the

collar

-

(The

position

of

the

collar

directly

controls the radial position

of

the

left hand end

of

the

cycle

clutch spring with respect

to the

cycle

shaft.

It determines

how

much

the

spring clutch wi

II

be expanded when

the

cycle

clutch

sleeve

is

latched

and

the

cycle

shaft

is

in

its rest position.) Adjust the

collar

so

that

when

a

zero

tilt,

negative-five

rotate

character

is

hand

cycled

the

cycle

clutch spring will begin to

slip

(expend) when the

cyc

I e shaft

i'S

1/16" to

3/32"

from

its rest position measured on the surface

of

check

ratchet

(Fig.

43.1).

This

adjustment

is

difficult

to observe

at

the

check

ratchet.

A 1/16" to 3/32" rotation

of

the

cycle

shaft

wi

II

cause the print shaft

gear

to turn

ap-

proximately one

tooth.

The

adjustment

can

easi

Iy

be read by one

of

the following methods.

2-12

1/16" to 1

/32

"

Cycle

Clutch

Check

Ratchet

FIGURE

43.1

Cycle

Clutch Spring And Collar Adjustment

(a) Print Shaft

Gear

Method

1. Hand

cycle

a

zero

tilt,

negative-five

char-

acter

until the

cycle

clutch begins to

slip.

2.

Pencil mark the print shaft bearing in line

with a tooth on the

gear.

3.

Release the

cycle

clutch

again

by depressing

a keybutton.

4.

Slowly hand

cycle

the machine until the

check

pewl just drops into a tooth on the

check

rat-

chet.

The

print shaft

gear

should have

rotat-

ed 1/2 to one

tooth.

If

the print shaft

gear

rotated further than one tooth the

collar

must

be moved top toward the

rear.

Less

than 1/2

to one

tooth,

move

it

top toward

the

front.

A

zero

ti It,

negative-five

rotate

character

is

used

because

it

offers the

greatest

resistance to the

cycle

shaft during the restoring portion

of

a

cycle,

caus-

ing the

cycle

clutch

spring to slip

at

the earl iest

possible

time.

NOTE: If the

collar

should become

completely

loose, a good starting

point

may be

obtained

by

positioning the

collar

so

that

its adjusting screw

head

is

approximately in line with

the

high point

of

the

negative-five

cam.

CAUTION:

The

cycle

clutch stop

attached

to the

collar

m9Y

prevent

the

shaft

from

reaching

the

.

latched position. Any change

in

the

cycle

clutch

collar

adjustment

wi

II

necessitate a readjustment

of

the

stop; therefore

it

is

usually best to loosen

the

stop before attempting to adjust the

collar.

Loading...

Loading...