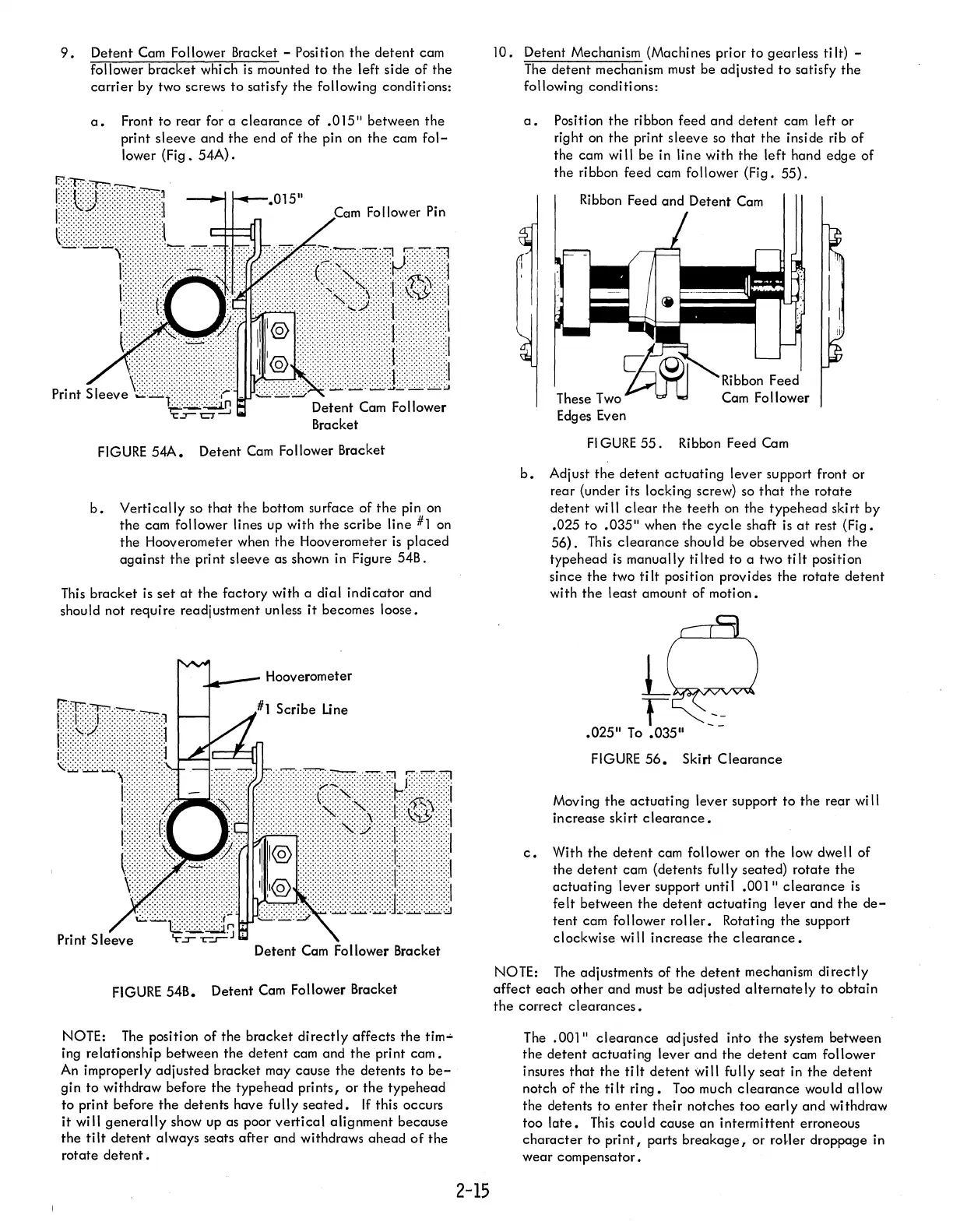

9.

Detent

Cam

Follower Bracket - Position

the

detent

cam

follower bracket which

is

mounted

to

the left side of the

carrier

by two screws

to

satisfy the following conditions:

a.

Front

to

rear for a

clearance

of

.015"

between the

print sleeve and the end of the pin

on

the cam

fol-

lower (Fig.

54A).

Cern

Follower

Pin

Detent

Cam

Follower

Bracket

FIGURE

54A.

Detent

Cam

Follower Bracket

b.

Vertically

so

that

the bottom surface of

the

pin on

the cam follower lines up with the scribe line

#1

on

the Hooverometer when the Hooverometer

is

placed

against

the

print sleeve as shown in Figure 54B.

This

bracket is

set

at

the factory with a dial indicator and

should not require readjustment unless

it

becomes loose.

c...._-

Hooverometer

Detent

Cam

Follower Bracket

FIGURE

54B. Detent

Cam

Follower Bracket

NOTE:

The

position

of

the bracket

directly

affects

the

tim-

ing relationship between the

detent

cam and the print

cam.

An

improperly adjusted bracket may cause the detents

to

be-

gin

to

withdraw before the typehead prints,

or

the

typehead

to

print before the detents have fully

seated.

If

this occurs

it

will

generally

show up as poor

vertical

alignment because

the

tilt

detent

always seats

after

and withdraws

ahead

of

the

rotate

detent.

2-15

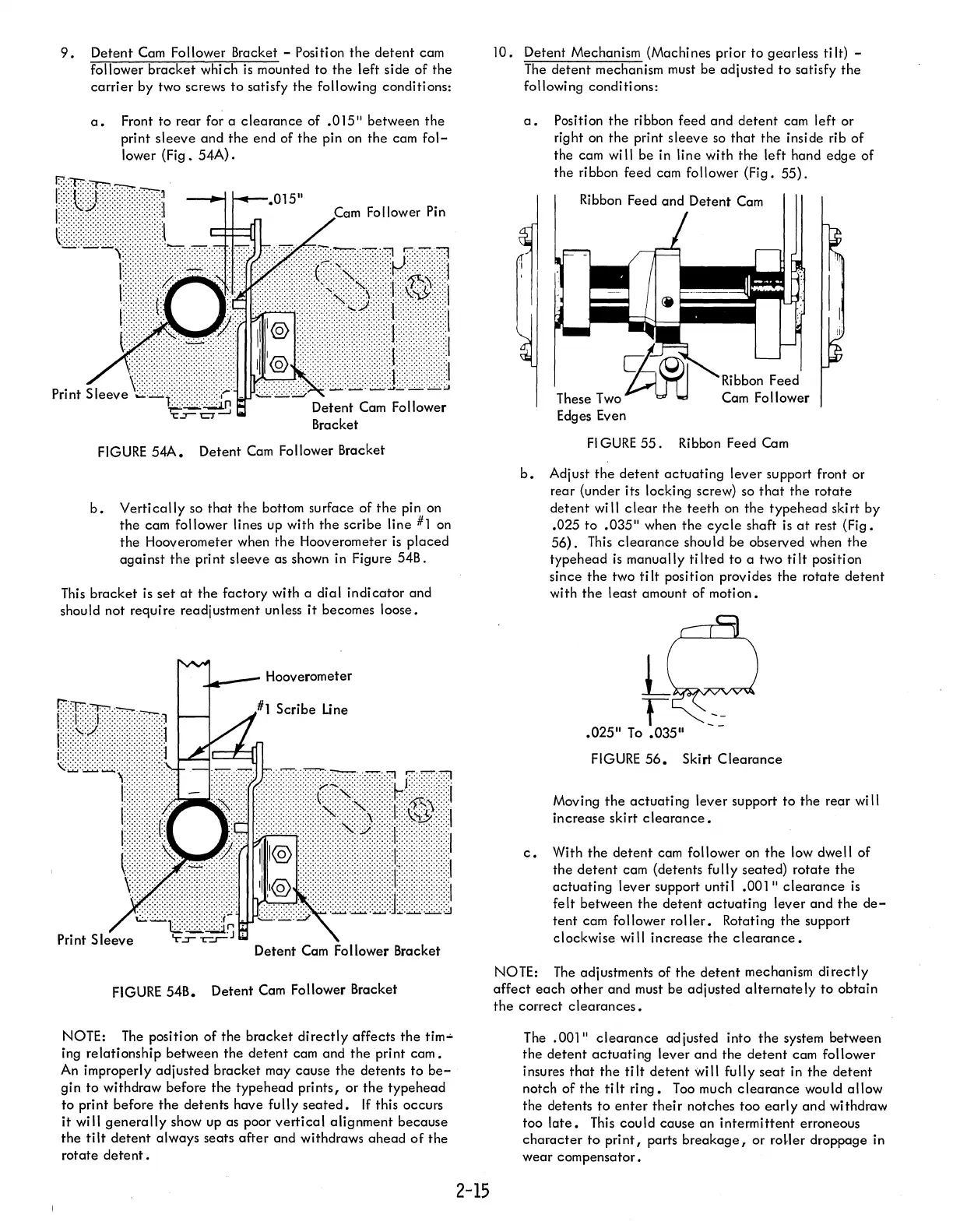

10.

Detent Mechanism (Machines prior

to

gearless ti

It)

-

The

detent

mechanism

must

be adjusted

to

satisfy the

following conditions:

a.

Position the ribbon feed and

detent

cam left or

right on the print sleeve

so

that

the insi de rib

of

the cam

wi

II

be in line with the left hand edge of

the ribbon feed cam

follower (Fig.

55).

Ribbon Feed and Detent

Cam

These

Two

Cam Follower

Edges Even

FI

GURE

55.

Ribbon Feed

Cam

b.

Adjust the

detent

actuating lever support front or

rear (under its locking screw) so

that

the rotate

detent will c lear the

teeth

on

the typehead ski rt by

.025

to

.035"

when the

cycle

shaft

is

at

rest (Fig.

56).

This

clearance

should be observed when the

typehead

is

manually

tilted

to

a two

tilt

position

since the two

tilt

position provides the rotate

detent

with

the

least amount of motion.

FIGURE

56.

Skirt

Clearance

Moving

the

actuating lever support to the rear

wi

II

increase skirt

clearance.

c.

With the

detent

cam follower

on

the

low dwe

II

of

the

detent

cam (detents

fu

II

y seated) rotate the

actuating lever support until

.001"

clearance

is

felt between the

detent

actuating lever and the

de-

tent

cam follower

roller.

Rotating the support

clockwise will increase the

clearance.

NOTE:

The

adjustments of the

detent

mechanism

directly

affect

each

other and must be adjusted

alternately

to obtain

the

correct

clearances.

The

.001"

clearance

adjusted into

the

system between

the

detent

actuating

lever and the

detent

cam follower

insures

that

the

tilt

detent

will fully

seat

in

the

detent

notch of the

tilt

ring.

Too

much

clearance

would allow

the detents

to

enter

their

notches too

early

and withdraw

too

late.

This

could cause an intermittent erroneous

character

to

print,

parts

breakage,

or roHer droppage in

wear compensator.

Loading...

Loading...