CAUTION:

Vertical

play

in the upper ball socket will

affect

vertical

alignment

and

impression because

the

type head

wi

II

not maintain a definite position.

Also,

care

must be taken

to

insure

that

the

entire

rotat.

system is free

from

binds.

A bind in

the

upper ball

sock-

et

can result

in

poor horizontal alignment

if

the

rotate

detent

fails

to

fully

seat

in

the

detent

notch before print

occurs.

An

excessive

bi

nd can cause unwanted roller

droppage in the wear compensator during a

negative

se-

lection.

Binds

in

the

system (carrier area) can

be

checked

by manually operating the shift arm in

and

out.

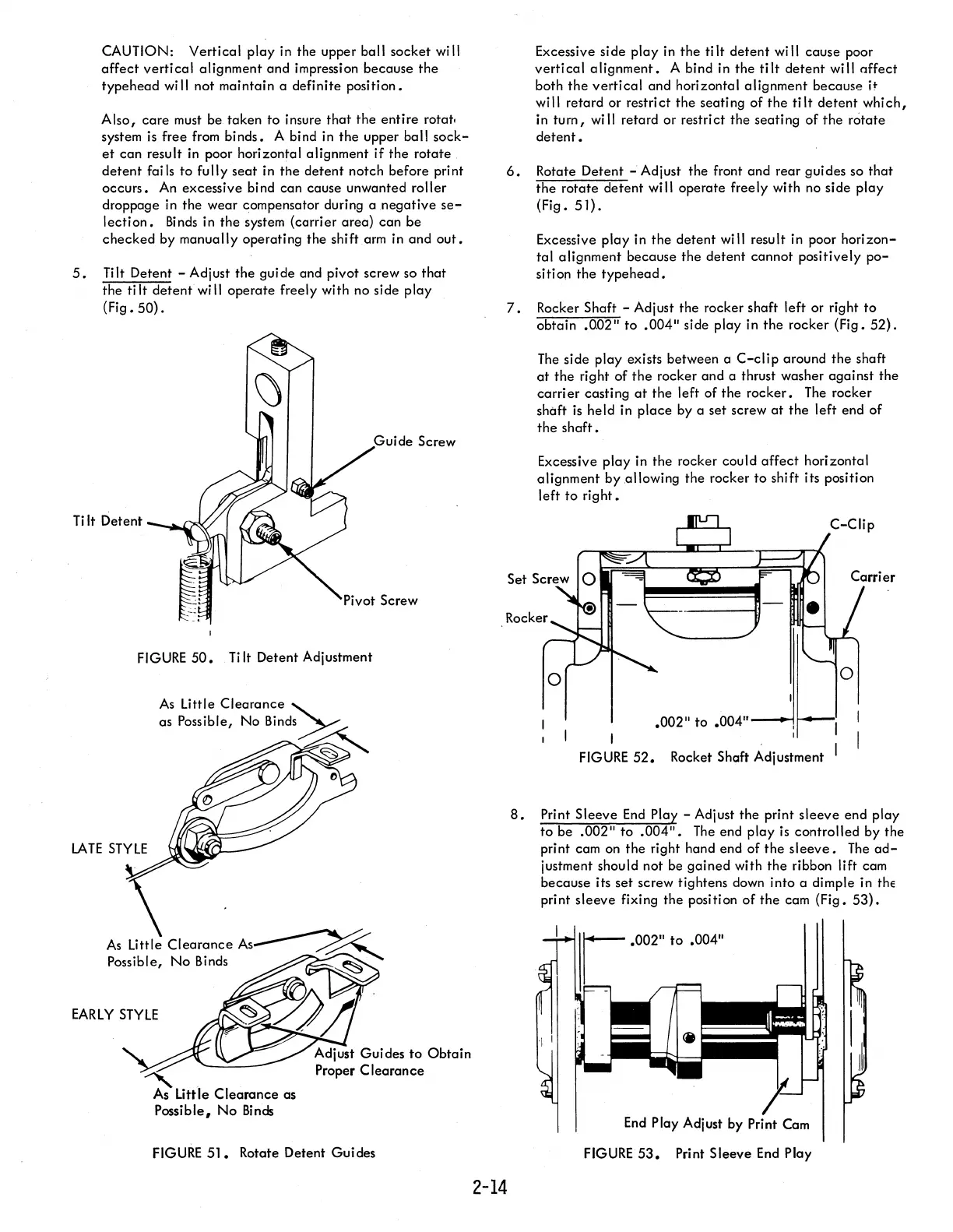

5.

Tilt Detent - Adjust

the

gui de and pivot screw so

that

the ti

It

detent

wi

II

operate

freely with no side

play

(Fig.

50).

Ti

It

Detent

FIGURE

50.

Ti

It

Detent Adj ustment

As

Little

Clearance

As~

Possible,

No

Binds

~

EARLY

STYLE

""

.

As

Little

Clearance

as

Possible,

No

Binds

Adjust Guides

to

Obtain

Proper

Clearance

FIGURE

51.

Rotate Detent Guides

Excessive side

play

in

the

tilt

detent

will cause poor

vertical

alignment.

A bind in the

tilt

detent

will offect

both

the

vertical

and horizontal alignment because H

will retard or restrict

the

seating of

the

tilt

detent

which,

in

turn,

will retard or restrict

the

seating

of

the

rotate

detent.

6.

Rotate Detent - Adjust the front

and

rear guides so

that

the

rotate

detent

will operate freely with no side play

(Fig.

51).

Excessive

play

in

the

detent

will result in poor

horizon-

tal

alignment because the

detent

cannot positively

po-

sition

the

typehead.

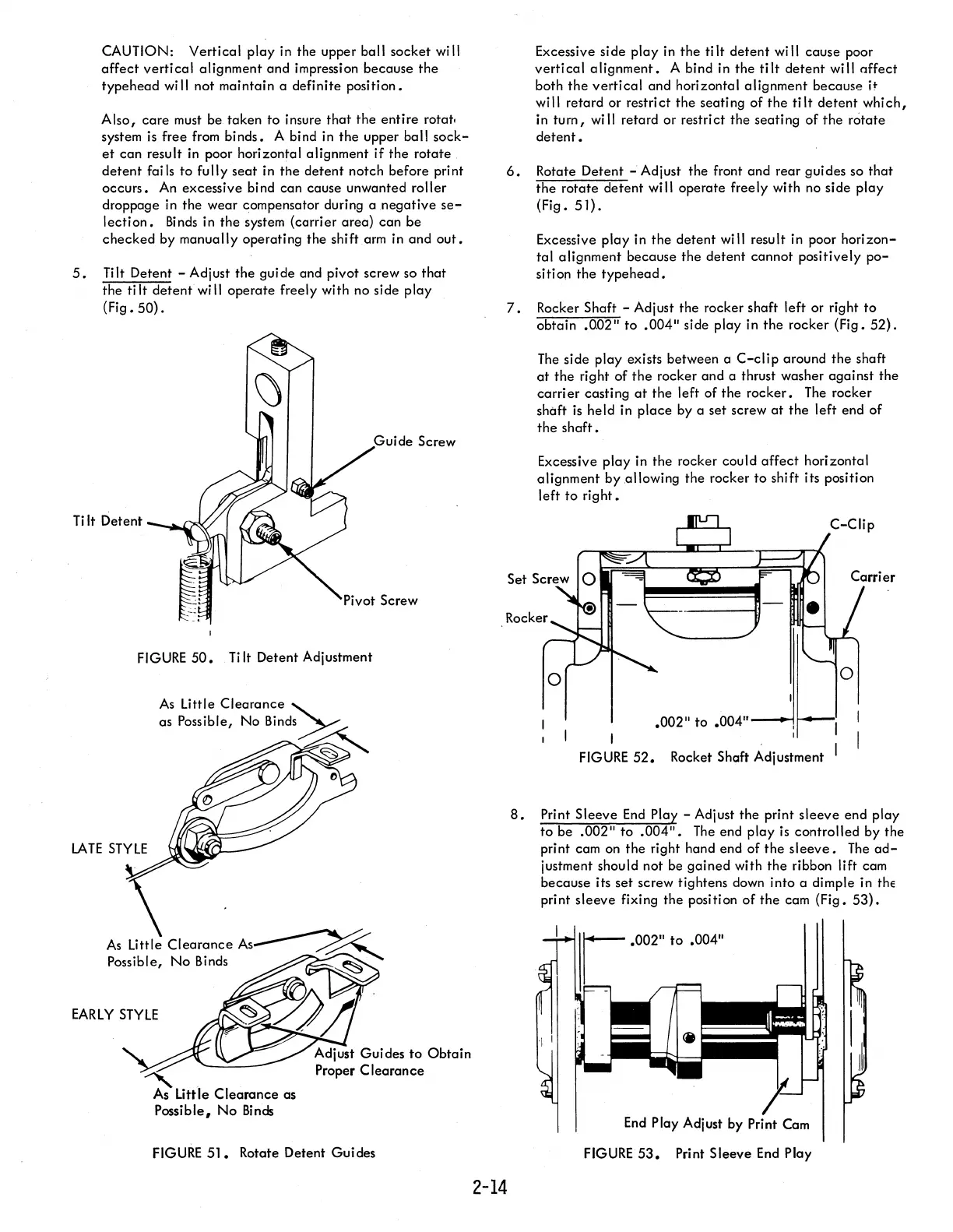

7.

Rocker Shaft - Adjust the rocker shaft left or right

to

obtain

.002"

to

.004"

side play in

the

rocker (Fig.

52).

The

side

play

exists between a

C-clip

around

the

shaft

at

the

right of

the

rocker and a thrust washer against the

carrier

casting

at

the

left of

the

rocker.

The

rocker

shaft

is

held in

place

by a set screw

at

the

left end of

the

shaft.

2-14

Excessive

play

in the rocker could

affect

horizontal

alignment

by allowing the rocker

to

shift its position

left

to

right.

FIGURE

52.

Rocket Shaft Adjustment

8.

Print Sleeve

End

Play - Adjust

the

print

sleeve

end play

to

be

.002"

to

.004".

The

end play is controlled by the

print cam on

the

right hand end of

the

sleeve.

The

ad-

justment should not be

gained

with

the

ribbon lift cam

because its set screw tightens down into a dimple in the

print

sleeve

fixing the position

of

the

cam (Fig.

53).

End

Play Adjust by Print Cam

FIGURE

53.

Print Sleeve

End

Play

Loading...

Loading...