FIGURE

47.

Ti

It

Tube End Play Adjustment

carrier.

The hole in

the

carrierandrockerwill

make the

tilt

pulley

set

screw

accessible

with a fluted

wrench.

NOTE:

The

height of

the

tilt

sector

gear

is

established

by shimming between

the

gear

and

the

top

of

the

yoke.

The height

is

set

to obtain

the

proper backlash between

the

ti

It

sector

gear

and

the

ti

It

ring

gear.

Be

sure

to

re-install

the

shim if disassembly

is

necessary.

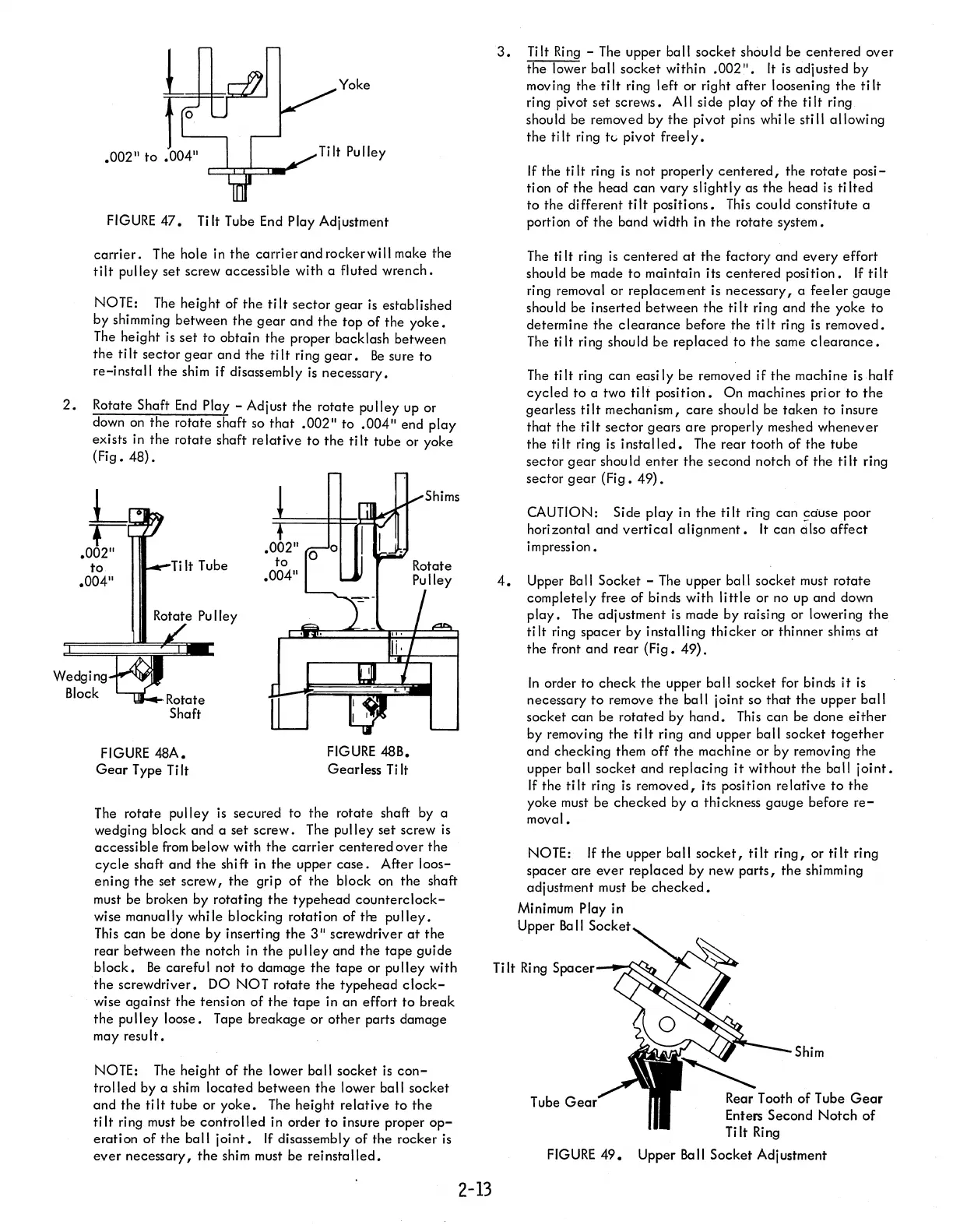

2.

Rotate Shaft

End

Play - Adjust

the

rotate

pu

lIey up or

down

on

the

rotate

shaft so

that

.002" to .004" end

play

exists in

the

rotate shaft

relative

to

the

tilt

tube or yoke

(Fig.

48).

L

"+

• 002"

to

.004"

Wedging

Block

FIGURE

48A.

Gear

Type Tilt

FIGURE

48B.

Gearless

Ti

It

The rotate

pulley

is

secured to

the

rotate shaft by a

wedging block and a set

screw.

The

pulley

set screw

is

accessible

from

below with

the

carrier

centered

over

the

cycle

shaft and

the

shift in

the

upper

case.

After loos-

ening

the

set

screw,

the

grip

of

the

block on

the

shaft

must be broken by rotating

the

typehead

counterclock-

wise manually while blocking rotation of

tf-e

pulley.

This

can be done by inserting

the

3" screwdriver

at

the

rear between

the

notch in

the

pulley

and

the

tape

guide

block.

Be

carefu I not

to

damage

the

tape

or

pu

Iley with

the

screwdriver. DO

NOT

rotate

the

typehead

clock-

wise against

the

tension

of

the

tape

in

an

effort

to

break

the

pulley

loose. Tape

breakage

or

other

parts damage

may

result.

NOTE: The height

of

the

lower ball

socket

is

con-

trolled

by a shim

located

between

the

lower ball socket

and

the

tilt

tube

or

yoke.

The height

relative

to

the

tilt

ring must be

controlled

in order

to

insure proper

op-

eration

of

the

ball

joint.

If

disassembly

of

the

rocker

is

ever

necessary,

the

shim must be

reinstalled.

2-13

3.

Tilt

Ring

- The upper ball socket should be

centered

over

the

lower ball

socket

within

.002".

It

is

adjusted by

moving

thetilt

ring left or right

after

loosening

the

tilt

ring pivot

set

screws. All side

play

of

the

tilt

ring

should be removed by

the

pivot pins while still allowing

the

ti

It

ring

tv

pivot

freely.

If

the ti

It

ring

is

not properly

centered,

the

rotate

posi-

tion of

the

head

can

vary

slightly

as

the

head

is

tilted

to the different

tilt

positions.

This

could

constitute a

portion

of

the

band width in

the

rotate

system.

The

ti

It

ring

is

centered

at

the

factory and

every

effort

should be made

to

maintain its

centered

position.

If

tilt

ring removal or

replacement

is

necessary,

a

feeler

gauge

should be inserted between

the

tilt

ring and

the

yoke to

determine

the

clearance

before

the

tilt

ring

is

removed.

The

tilt

ring should

be

replaced

to

the

same

clearance.

The

tilt

ring

can

easily

be

removed

if

the

machine

is·half

cycled

to

a two

tilt

position.

On

machines prior to

the

gearless

tilt

mechanism,

care

should be

taken

to insure

that

the

ti

It

sector

gears

are

properly meshed whenever

the

tilt

ring

is

installed.

The

rear

tooth

of

the

tube

sector

gear

shou

Id

enter

the

second notch

of

the ti

It

ring

sector

gear

(Fig.

49).

CAUTION: Side

play

in

the

tilt

ring can 9duse poor

horizontal and

vertical

alignment.

It

can

61so

affect

impression •

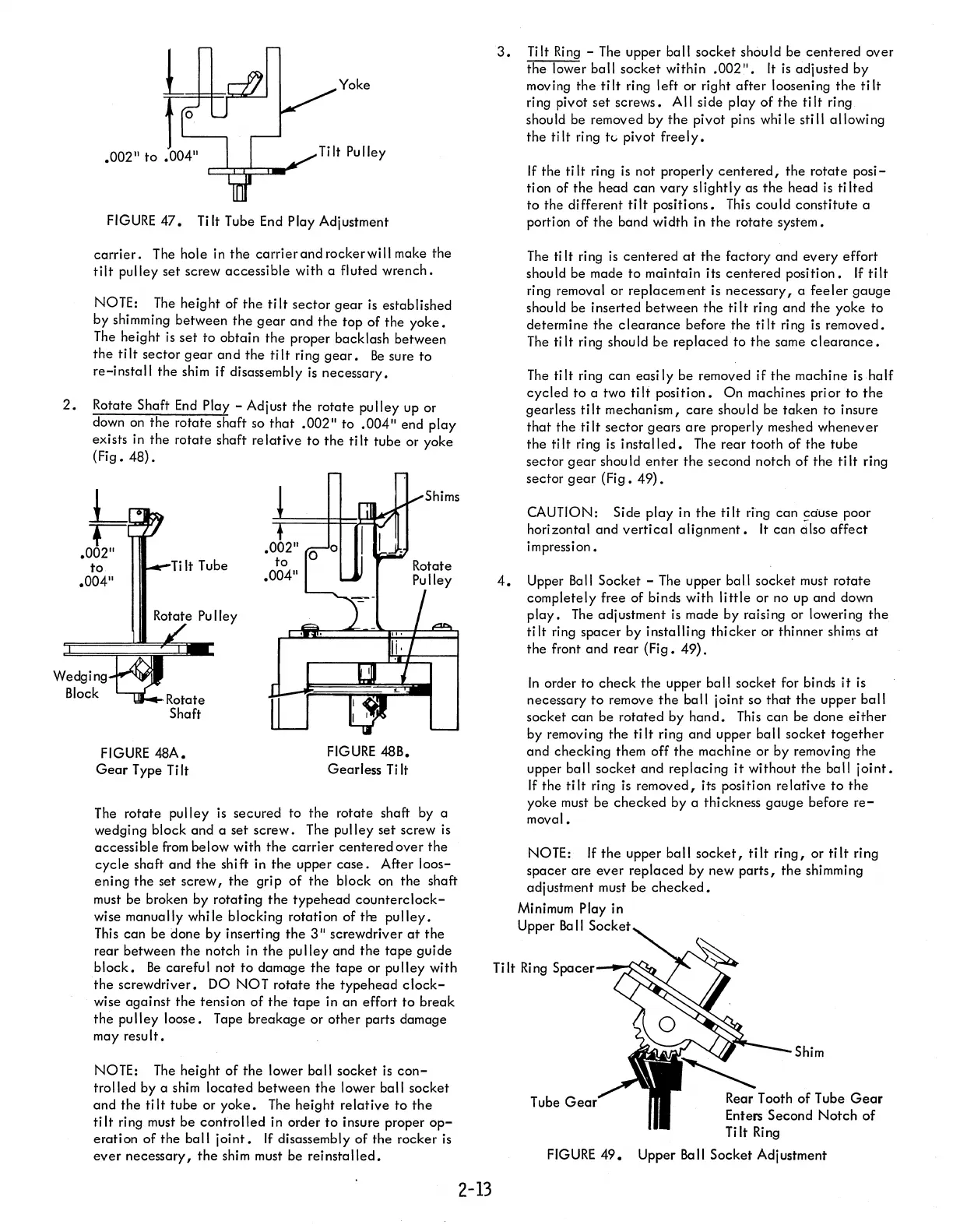

4.

Upper Ball Socket - The upper ball socket must

rotate

completely free of binds with

little

or no up and down

play.

The

adjustment

is

made by raising or lowering

the

tilt

ring

spacer

by installing

thicker

or thinner

shi~s

at

the

front and rear

(Fig.

49).

In

order

to

check

the

upper ball socket for binds

it

is

necessary

to

remove

the

ball joint so

that

the

upper

ball

socket

can

be

rotated

by

hand.

This

can

be done

either

by removing

the

tilt

ring and upper ball socket

together

and checking them off

the

machine

or

by removing

the

upper ball socket

and

replacing

it

without

the

ball

joint.

If

the

tilt

ring is removed, its position

relative

to

the

yoke must be

checked

by a thickness

gauge

before

re-

moval.

NOTE:

If

the

upper ball

socket,

tilt

ring,

or

tilt

ring

spacer

are

ever

replaced

by new

parts,

the

shimming

adjustment must be

checked.

Minimum Play in

Upper

Be

II

Socket

Ti

It

Ri

ng

C:"",. ..

,r

__

-C

Tube G

FIGURE

49.

Shim

Rear Tooth

of

Tube

Gear

Enters Second

Notch

of

Tilt

Ring

Upper

Be

II

Socket Adj ustment

Loading...

Loading...