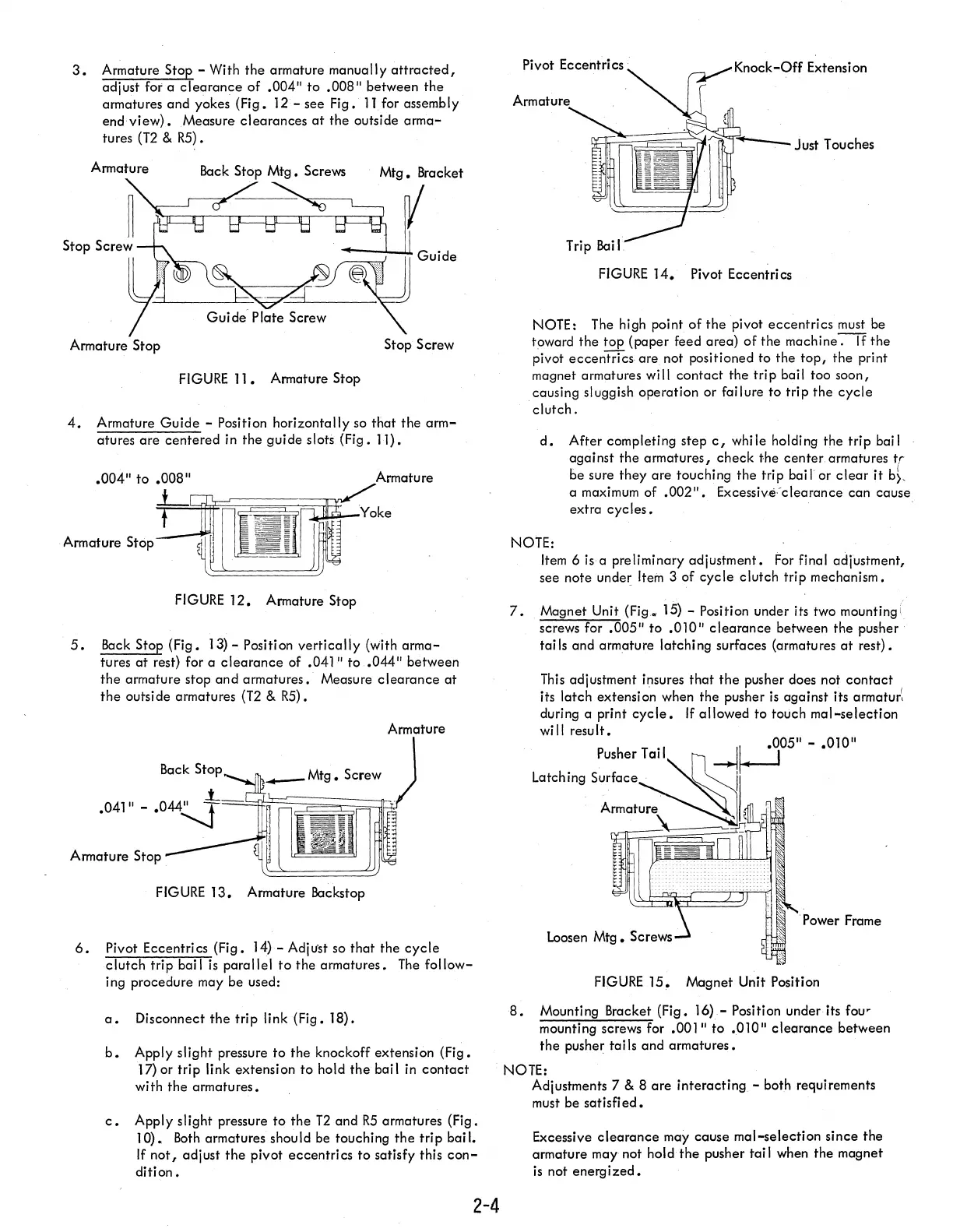

3.

Armature Stop - With

the

armature manually

attracted,

adjust for a

clearance

of

.004"

to

.008"

between

the

armatures and yokes (Fig. 12 - see Fig. 11 for assembly

end view)

• Measure

clearances

at

the outside

arma-

tures

(T2

& R5).

Armature

Mtg.

Bracket

'-..c,r-=

___

~~

Gu;d,

Armature Stop Stop Screw

FIGURE

11.

Armature Stop

4.

Armature

Guide

- Position horizontally so that the

arm-

atures

are

centered

in the guide slotS (Fig. 11).

.004"

to

.008"

Armature

Armature Stop

FIGURE

12.

Armature Stop

5.

Back Stop (Fig. 13) - Position

vertically

(with

arma-

tures

at

rest) for a

clearance

of

.041"

to

.044"

between

the

armature stop

and

armatures. Measure

clearance

at

the

outside armatures

(T2

& R5).

Armature

I~"'

__

Mtg.

Screw

.041"

-

Armature Stop

FIGURE

13.

Armature Backstop

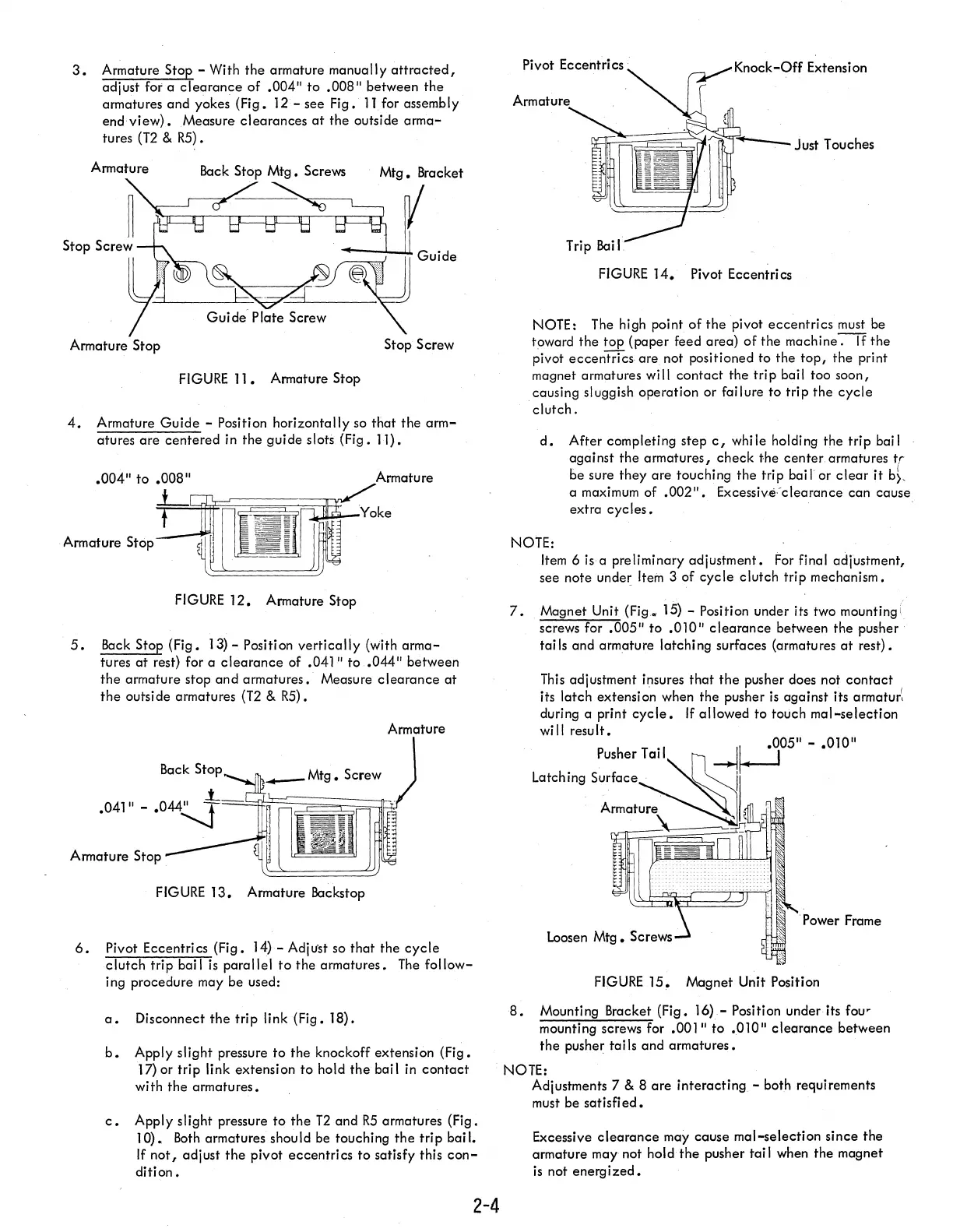

6.

Pivot Eccentrics (Fig.

14)-

Adjust so

that

the

cycle

clutch

trip

bail

is

parallel

to

the armatures.

The

follow-

ing procedure may be used:

a.

Disconnect

the

trip

link (Fig. 18).

b.

Apply slight pressure

to

the knockoff extension (Fig.

17)or

trip link extension

to

hold

the

bail in

contact

with

the

armatures.

c.

Apply slight pressure to

the

T2

and

R5

armatures (Fig.

10).

Both

armatures should be touching

the

trip

bail.

If

not,

adjust

the

pivot eccentrics

to

satisfy this

con-

dition.

2-4

Arm

581~~~~~fr"'''''''~---

Just Touches

FIGURE

14.

Pivot Eccentrics

NOTE: The high point

of

the

pivot

eccentrics

must be

toward

the

top

(paper feed area)

of

the machine

~

the

pivot

eccentrics

are. not positioned to the

top,

the

print

magnet armatures will

contact

the

trip

bail too soon,

causing sluggish operation or failure to

trip

the

cycle

clutch.

d.

After completing step

c,

while holding the trip bail

against

the

armatures,

check

the center. armatures

tr

be sure

they

are touching

the

trip

ban

or

clear

it

b},

a maximum of

.002".

ExcessiveVclearance can cause

extra

cycles.

NOTE:

Item

6

isa

preliminary adjustment.

For

final adjustment,

see note

unde~

Item 3 of

cycle

clutch trip mechanism.

7.

Magnet Unit

(Fig.

15) - Position under its two mounting (

screws for

.005"

to

.010"

clearance

between the

pusher·

tai

Is

and armature latching surfaces (armatures

at

rest).

This

adjustment insures

that

the

pusher does not

contact

its latch extension when the pusher

is

against its armatur'.

during a print

cycle.

If

allowed to touch

mal-selection

wi

II

resu

It.

Pusher Tail

-Ij-J05"

-

.010"

Latching

surface~.

II

Armature •

'- .

. Power Frame

FIGURE

15~

Magnet Unit Position

8.

Mounting Bracket (Fig.

16).-

Position under its

fou'

mounting screws for

.001"

to

.010"

clearance

between

the

pusher tai

Is

and

armatures.

NOTE:

Adjustments 7

& 8

are

interacting - both requirements

must be

satisfied.

Excessive

clearance

may cause mal-selection since the

armature may not hold

the

pusher tai I when the magnet

is

not

energized.

Loading...

Loading...