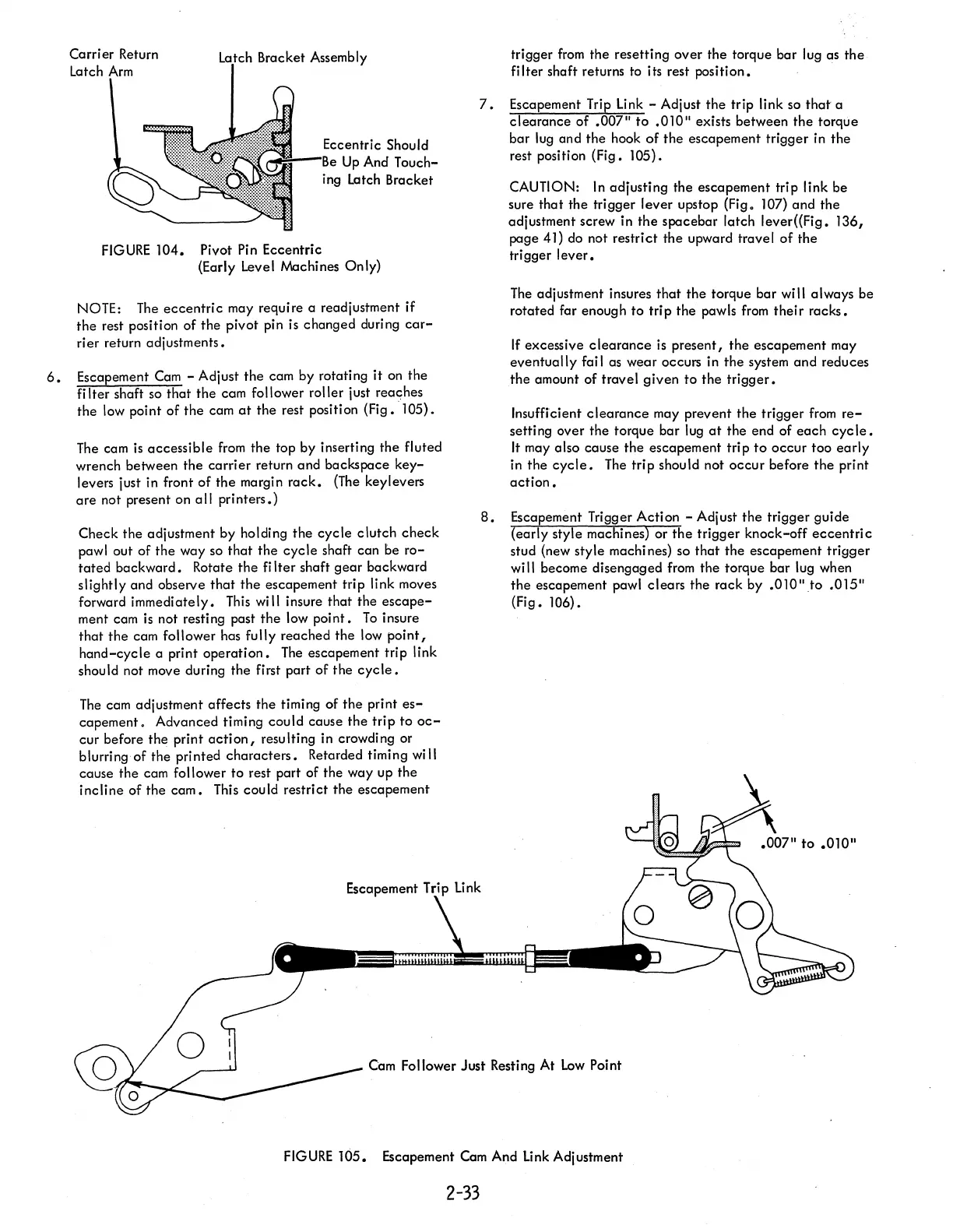

Carrier Return

Latch

Arm

Bracket Assembly

Eccentric Should

.-.l:=;'--I~",

Up

And T

ouch-

ing Latch Bracket

FIGURE

104.

Pivot Pin Eccentric

(Early Level Machines

Only)

NOTE:

The

eccentric

may require a readjustment

if

the

rest position of the pivot pin is changed during

car-

ri

er

return adj ustments •

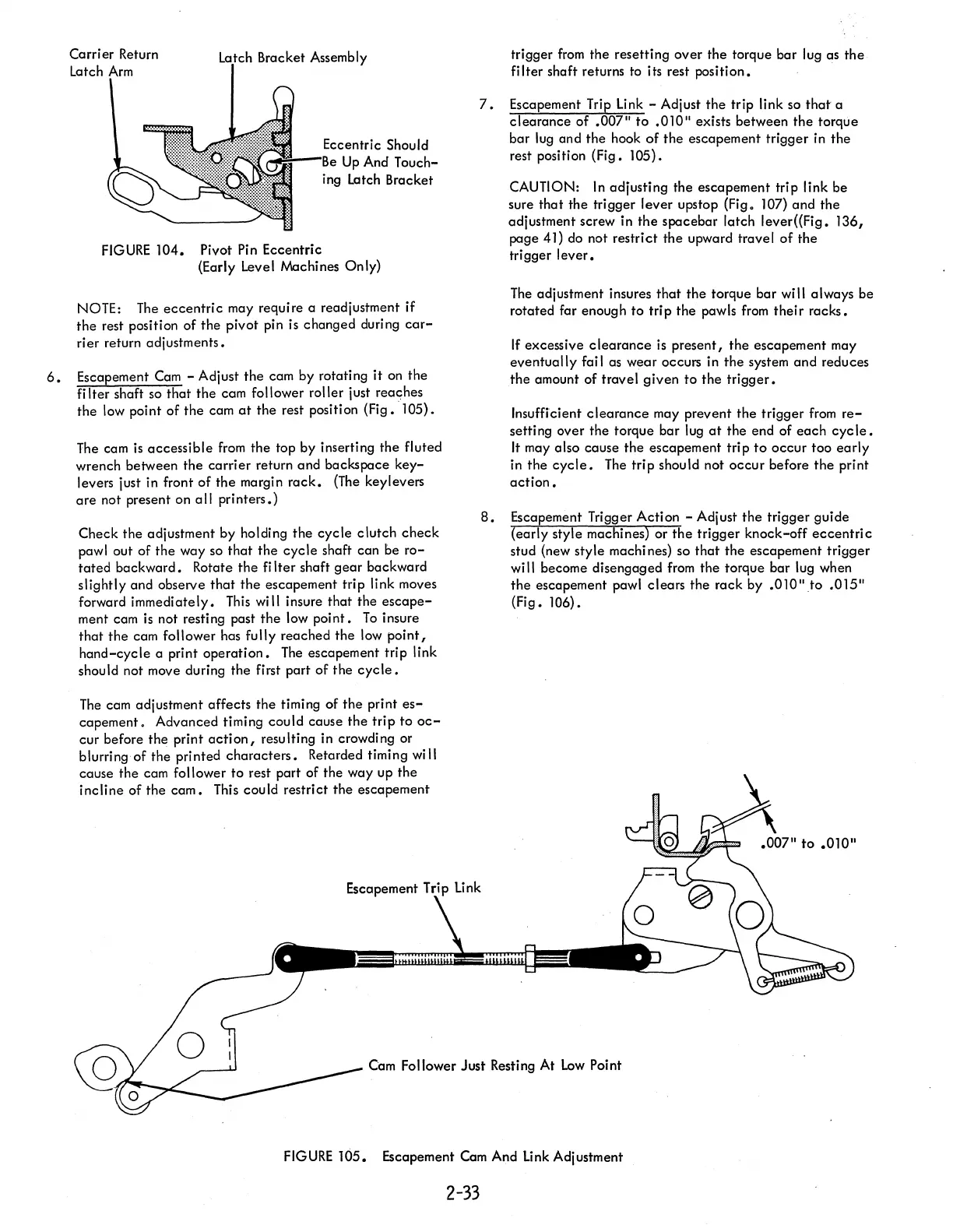

6.

Escapement

Cam

- Adjust

the

cam by rotating

it

on

the

filter

shaft so

that

the cam follower roller just reaches

the

low point of

the

cam

at

the rest position (Fig. ·105).

The

cam

is

accessible

from

the top by inserting the fluted

wrench between

the

carrier

return and backspace

key-

levers just in front

of

the

margin

rack.

(The

keylevers

are

not present on

all

printers.)

Check the adjustment by holding

the

cycle

clutch

check

pawl out of

the

way so

that

the

cycle

shaft can be

ro-

tated

backward. Rotate

the

filter

shaft

gear

backward

slightly and observe

that

the

escapement

trip

link moves

forward immediately.

This

will insure that the

escape-

ment cam

is

not resting past

the

low

point.

To

insure

that

the

cam follower has fully reached

the

low

point,

hand-cycle

a print

operation.

The

escapement trip link

should not move during the first part of

the

cycle.

The

cam adjustment affects the timing of

the

print

es-

capement.

Advanced timing

could

cause

the

trip

to

oc-

cur before

the

print

action,

resulting in crowding or

blurring of the printed

characters.

Retarded timing will

cause the cam follower to rest part of the way up the

incline

of

the

cam.

This could restrict

the

escapement

trigger

from

the resetting over the torque

bar

lug as

the

fi

Iter shaft returns to its rest position.

7.

Escapement Trip Link - Adjust

the

trip link so

that

a

clearance

of

.007"

to

.010"

exists between the torque

bar lug and

the

hook

of

the

escapement trigger in

the

rest position (Fig. 105) .

CAUTION:

In

adjusting the escapement trip link be

sure

that

the trigger lever upstop (Fig. 107) and the

adjustment screw in

the

spacebar

latch

lever«Fig.

136,

page 41) do not restrict the upward travel

of

the

trigger

lever.

The

adjustment insures

that

the

torque bar will always be

rotated far enough

to

trip

the pawls

from

their

racks.

If

excessive

clearance

is

present,

the

escapement may

eventually

fai I as

wear

occurs in

the

system

and

reduces

the

amount of travel

given

to

the

trigger.

Insufficient

clearance

may prevent

the

trigger

from

re-

setting over the torque bar lug

at

the end of

each

cyc

Ie.

It

may also cause

the

escapement

trip

to

occur

too

early

in

the

cycle.

The

trip

should not

occur

before

the

print

action.

8.

Escapement Trigger Action - Adjust

the

trigger guide

(early style machines) or

the

trigger knock-off

eccentric

stud (new style machi nes) so

that

the

escapement

trigger

wi

II

become disengaged

from

the

torque bar lug when

the

escapement pawl clears

the

rack by

.010"

to

.015"

(Fig. 106).

Cam Follower Just Resting At

Low

Point

FIGURE

105.

Escapement Cam And Link Adjustment

2-33

Loading...

Loading...