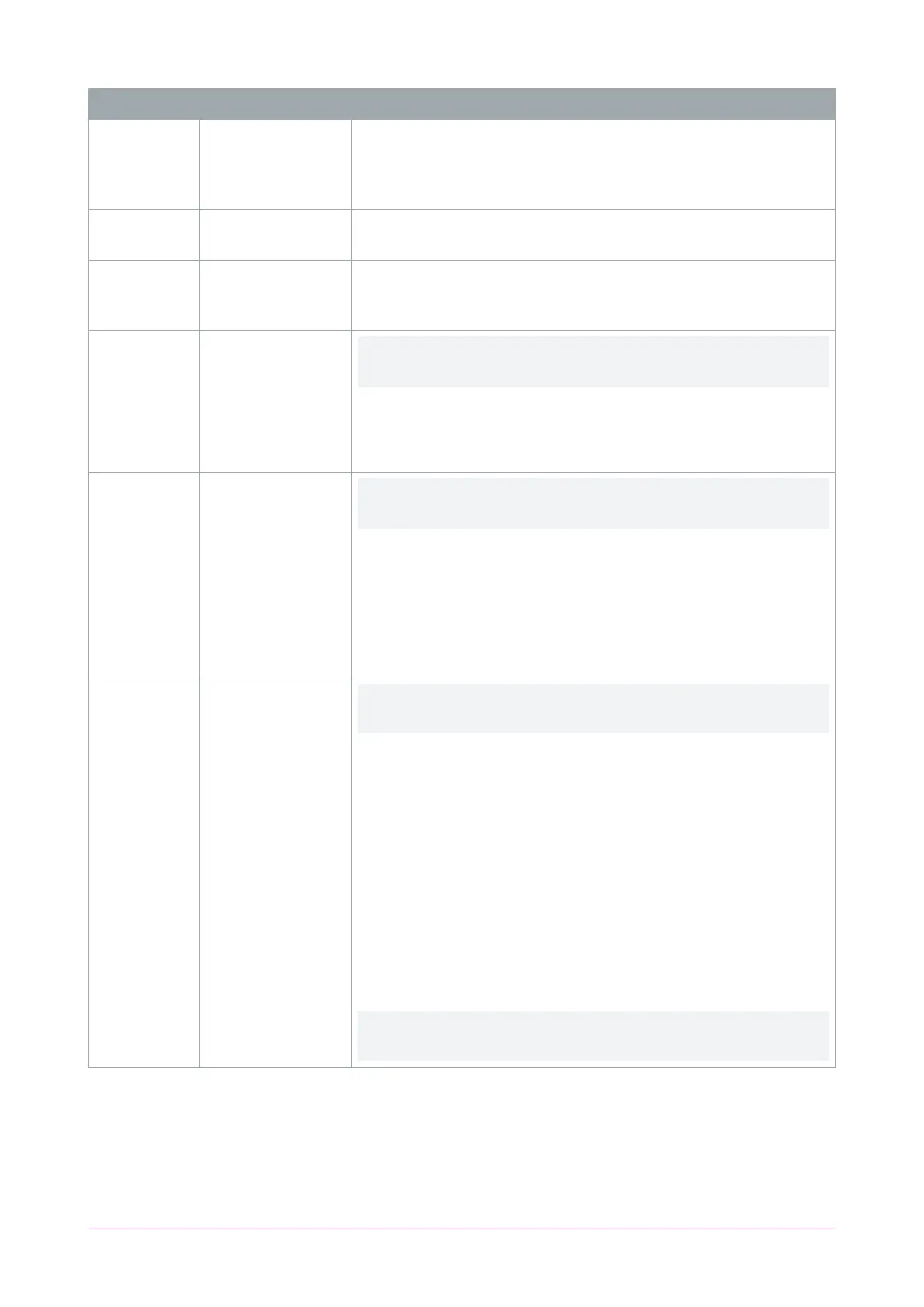

Task Frequency Description

Replace

battery

Once per 3-5 years,

or as specified by the

battery manufacturer

Replace each power supply battery as required with another of

equivalent or better specifications. Record the installation date of the

new battery in the system maintenance records and in a clearly visible

location within the equipment enclosure or on the battery itself.

Check keypad

keys

Once per year

Check the operation of every key on the keypad, that all keys are clearly

legible and that the keypad backlighting is operational.

Check keypad

display

Once per year

Check the operation of the keypad display to ensure that all characters

display correctly on the screen and that the backlight is operational and

at the correct brightness.

Test the

primary

reporting

service

As agreed between

monitoring company

and client, but not

less than once per

year

Note: This procedure must be pre-arranged in consultation with the

monitoring station.

⦁ Ensure that the system is 'on test'.

⦁ Perform an operation that triggers reporting.

⦁ Check that the system reports successfully.

Test the

backup

reporting

service

As agreed between

monitoring company

and client, but not

less than once per

year

Note: This procedure must be pre-arranged in consultation with the

monitoring station.

⦁ Disable the primary reporting service.

⦁ Perform an operation that triggers a reportable alarm.

⦁ Check that the system correctly reports alarm to the backup

reporting service after failing to communicate with the primary

service.

⦁ Re-enable the primary reporting service.

Test system

inputs and

areas

programmed

to report

As agreed between

monitoring company

and client, but not

less than once per

year

Note: This procedure must be pre-arranged in consultation with the

monitoring station.

⦁ Consult the maintenance sheets for a list of all inputs to be tested.

⦁ Activate each input by causing it to switch from the closed state to

open (alarm) and back to closed.

⦁ Check the system event log for associated open/close events.

⦁ Check off each input on the maintenance sheet after successful

testing and report any discrepancies.

⦁ Return all alarm areas to their pre-test states.

⦁ Obtain an activity report of all input opens/closes and area

alarms/restores from the monitoring station.

⦁ Compare the monitoring station report with the system event log

for the period to ensure that all tested inputs and areas reported

correctly. Record and report any discrepancies.

Special testing equipment and procedures may be required for smoke,

heat, seismic glass-break and other detectors.

PRT-CTRL-DIN | Protege GX DIN Rail Integrated System Controller | Installation Manual 48

Loading...

Loading...