43

The reverse drive sensor prevents the running-over of the supply hose while traveling

in reverse, thereby the sensor prevents the damage of the supply hose. Check the

function regularly. (see 4.2.2 Checking and fine-tuning of the reverse drive sensor)

This maintenance work must be performed regularly and is not covered by the

manufacturer´s product warranty.

The air duct and the rotating electrical duct in the drum hub do not require maintenance.

4.2.2 Checking and fine-tuning of the reverse drive sensor

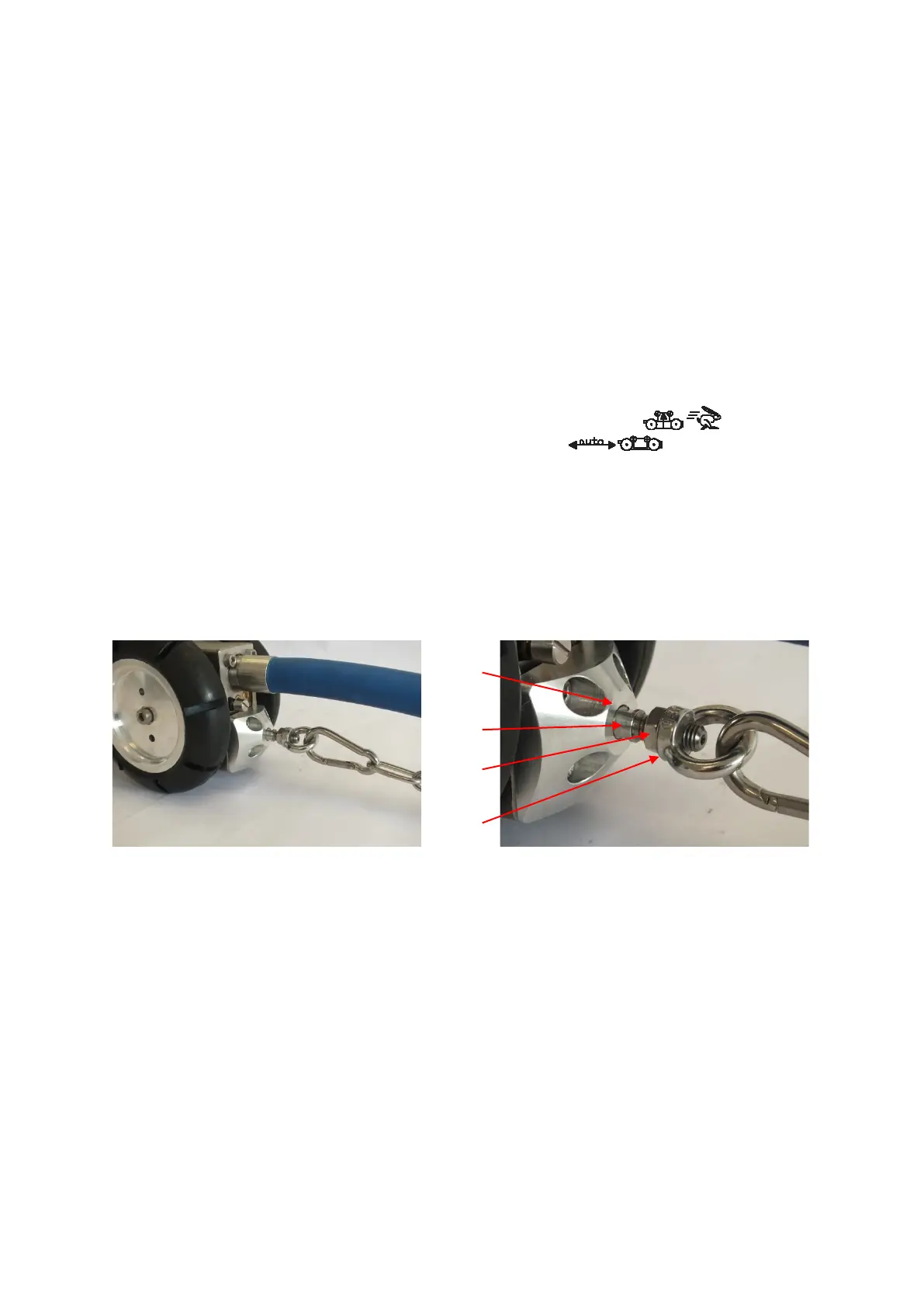

The reverse drive sensor is located on the rear side of the cutter drive, below the supply hose.

If the reverse driving is switched on and the supply hose is pulled taut, the cutting robot must

drive backwards. The hinged carabiner with chain serves as a strain relief and is necessarily

to be hooked in before driving into the pipe.

The function of the reverse drive sensor must be controlled regularly and readjusted if required.

For that purpose, position the cutter drive at ground level and unreel approx. 3 meters of the

supply hose. Set the left-hand function switch on the control unit to F2 / (fast driving

with pressure rail) and the right-hand function switch to F3 / (automatic driving).

Steer the left-hand joystick on the control unit backwards (reverse driving).

With tautly drawn supply hose the cutter drive is moving fast backwards. If the supply hose

isn´t pulled taut, the cutter drive is moving in the creeping mode and stops after a few seconds.

Now once again, pull on the supply hose from a distance of approx. 3 meters. Do not lift the

hose; lead the hose just above the ground level. The reverse drive sensor must trigger after

gently pulling on the hose; the cutter drive moves backwards again. If the cutter drive moves

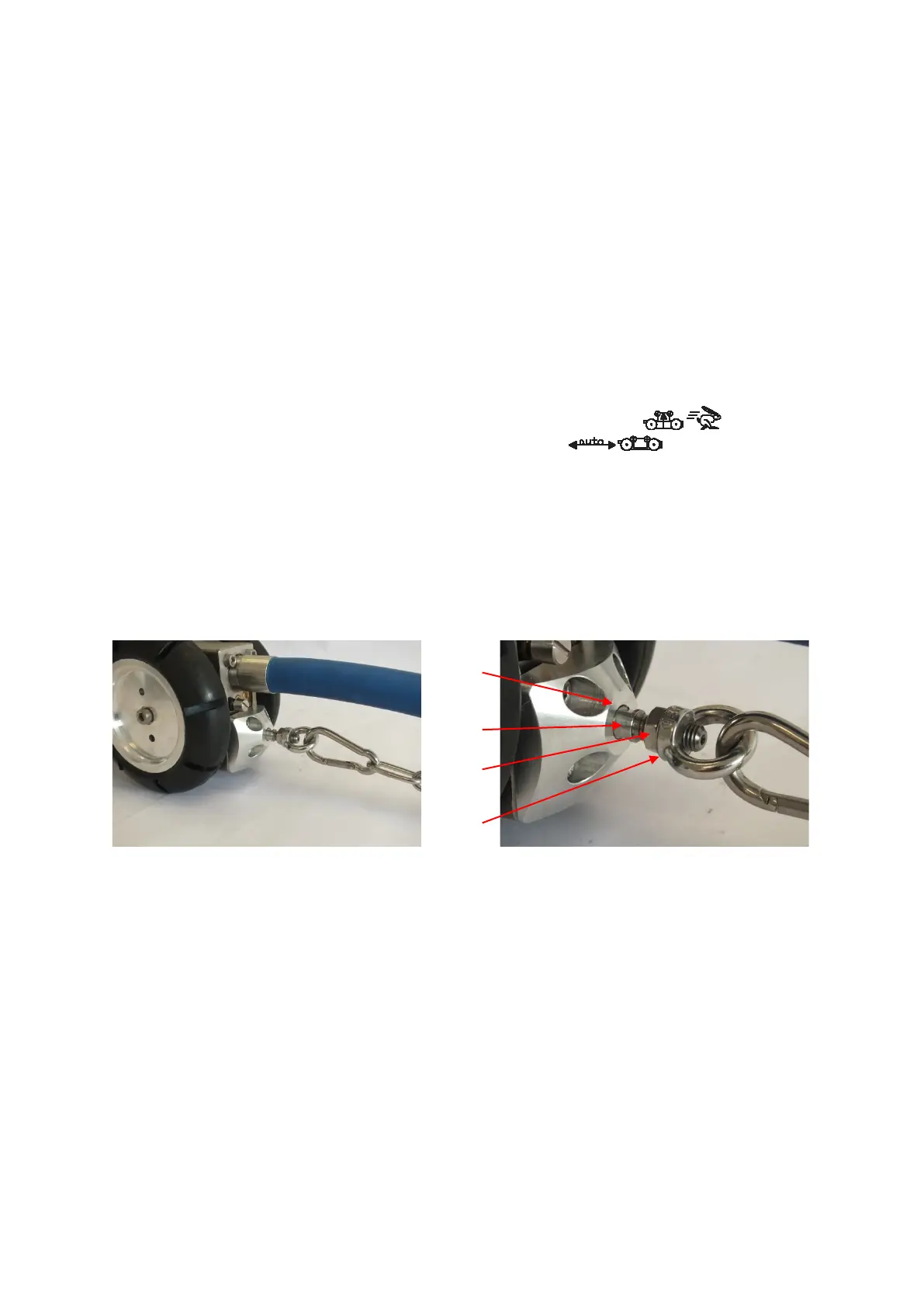

only at significant effort, or not at all; then loosen the counter nut at the ring bolt and screw in

the ring bolt for one turn. Repeat the test as long as the reverse drive sensor triggers lightly.

1 Reverse drive sensor

2 8 mm tool surface

3 Counter nut

4 Ring bolt

Loading...

Loading...