11

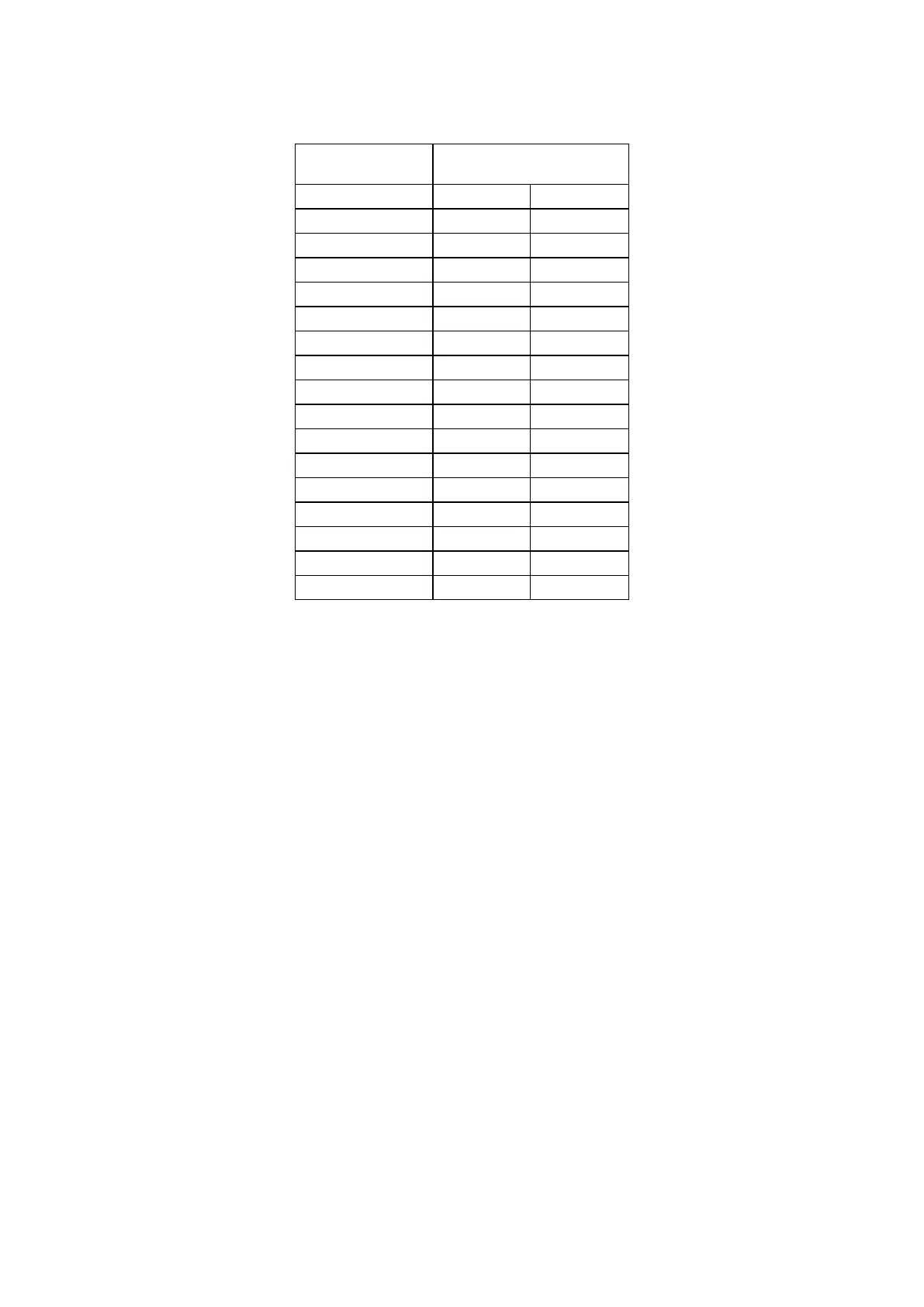

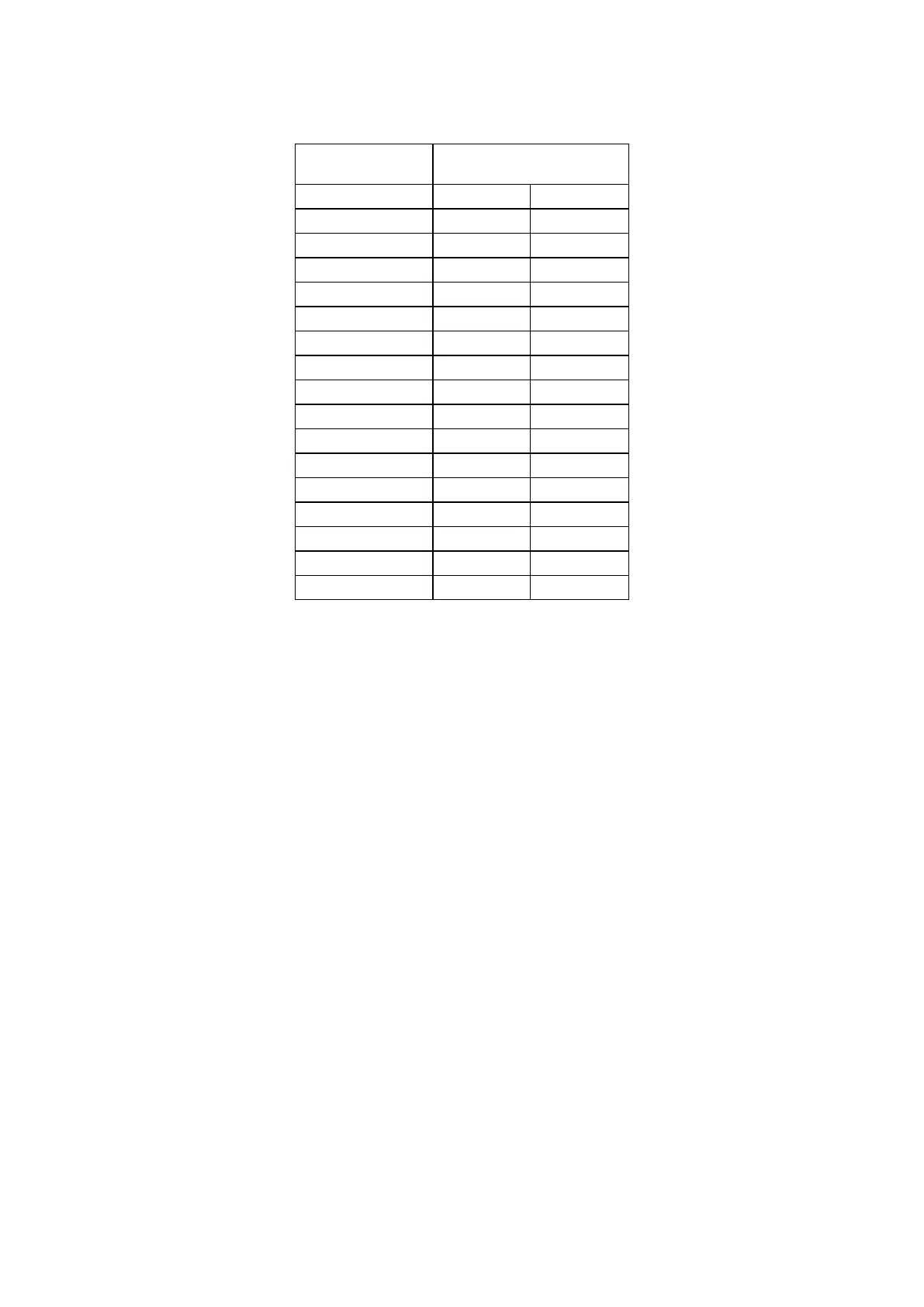

The following bolts must be used in order to ensure a sufficient screw-in-depth. Warning!

Bolts that are too long can cause damage to the cutter drive.

2.3 Device operation

- Check the completeness of the assemblies and accessories as well as the supply

media in the required quality!

- Set up the cutter drive to the required nominal-width (see 0 ).

- Transport the cutter drive (with camera and cutter motor), the chassis and the

accessories to the chosen work area (manhole, etc.).

- The chassis must be located in the immediate vicinity of the manhole; if not possible,

use deflection rollers.

- Unwind the hose package (as far as necessary for introduction into the manhole or

inspection opening) from the drum!

- The hose package must not be pulled over sharp edges or bent when being handled.

- Optional: Connect the meter counting and the keyboard (see 2.10.2 Meter counting

(optional)

Loading...

Loading...