TLE5012B

Interfaces

User’s Manual 46 Rev. 1.2, 2018-02

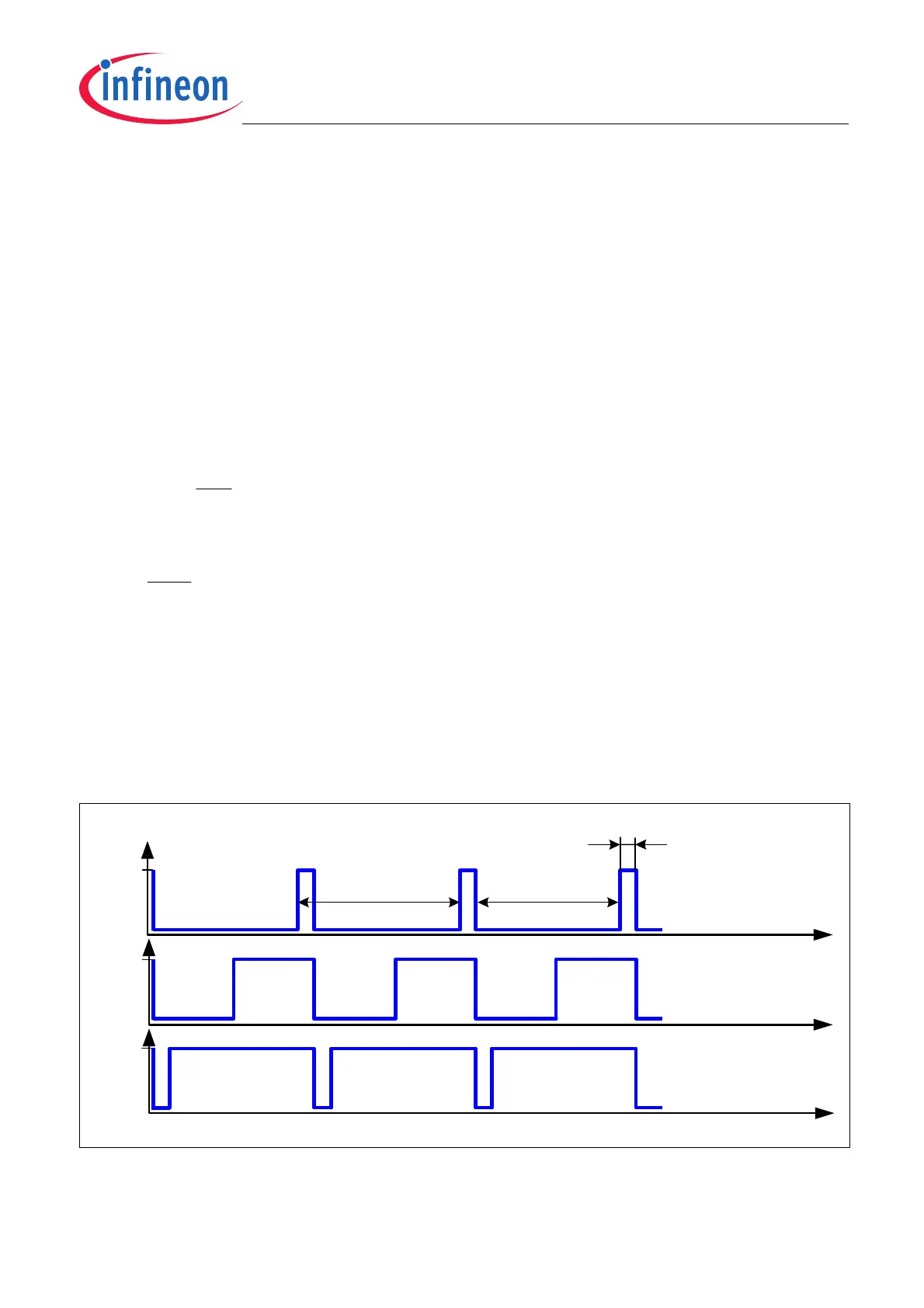

5.3 Pulse Width Modulation Interface

The Pulse Width Modulation (PWM) interface can be selected via SSC (IF_MD = ‘01’) in the register MOD_4.

The PWM update rate can be programmed within the register 0E

H

(IFAB_RES) in four possible steps with 12-bit

resolution (including diagnostics):

• ~0.25 kHz

• ~0.5 kHz

• ~1.0 kHz

• ~2.0 kHz

PWM uses a square wave with constant frequency whose duty cycle is modulated according to the last measured

angle value (AVAL register).

Figure 5-11 shows the principal behavior of a PWM with various duty cycles and the definition of timing values.

The duty cycle of a PWM is defined by the following general formulas:

(5.6)

The duty cycle range between 0 - 6.25% and 93.75 - 100% is used only for diagnostic purposes. In case the sensor

detects an error, the corresponding error information will be transmitted by the PWM duty cycle, either in the lower

(0 - 6.25%) or upper (93.75 - 100%) diagnostic range, depending on the kind of error (see “Output duty cycle

range” in Table 5-7). As long as a fault is present, the error information will be transmitted in PWM frames. This

diagnostic function can be disabled via the MOD_4 register (see Chapter 6.2).

Sensors with preset PWM are available as TLE5012B E5xxx. The register settings for these sensors can be found

in Chapter 6.2.

Figure 5-11 Typical example of a PWM signal

PWM

PWM

offonPWM

PWM

on

t

f

ttt

t

t

CycleDuty

1

=

+=

=

t

ON

‚0'

t

ON = High level OFF = Low level

Duty cycle = 6.25%

Duty cycle = 50%

Duty cycle = 93.75%

t

PWM

t

OFF

Vdd

U

IFA

Vdd

U

IFA

t

‚0'

t

Vdd

U

IFA

‚0'

Loading...

Loading...