NV11 Manual Set – Section 2 3

Copyright © Innovative Technology Ltd 2012 GA963-2

2. FIELD SERVICE MANUAL

This section is one part of a complete manual set: typically, a field service engineer

who is maintaining the product would use this section.

This section contains the essential information that the field engineer needs to clean,

maintain and fault find an NV11 validator that is installed in a host machine.

The NV11 validator has been designed to minimise any problems or performance

variations over time. This has been achieved by careful hardware and software

design; this attention to the design means there is very little user maintenance

required.

2.1 Cleaning

The NV11 validator has been designed in a way to prevent damage and airborne

contamination reaching the optical sensors; however, depending upon the

environment the NV11 may require occasional cleaning or belt changing.

Do not use solvent based cleaners such as

alcohol, petrol, methylated spirits, white spirit or

PCB cleaner. Using these solvents can cause

permanent damage to the unit; only use a mild

detergent solution as directed below.

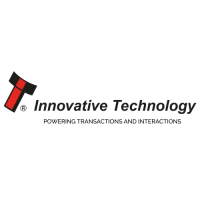

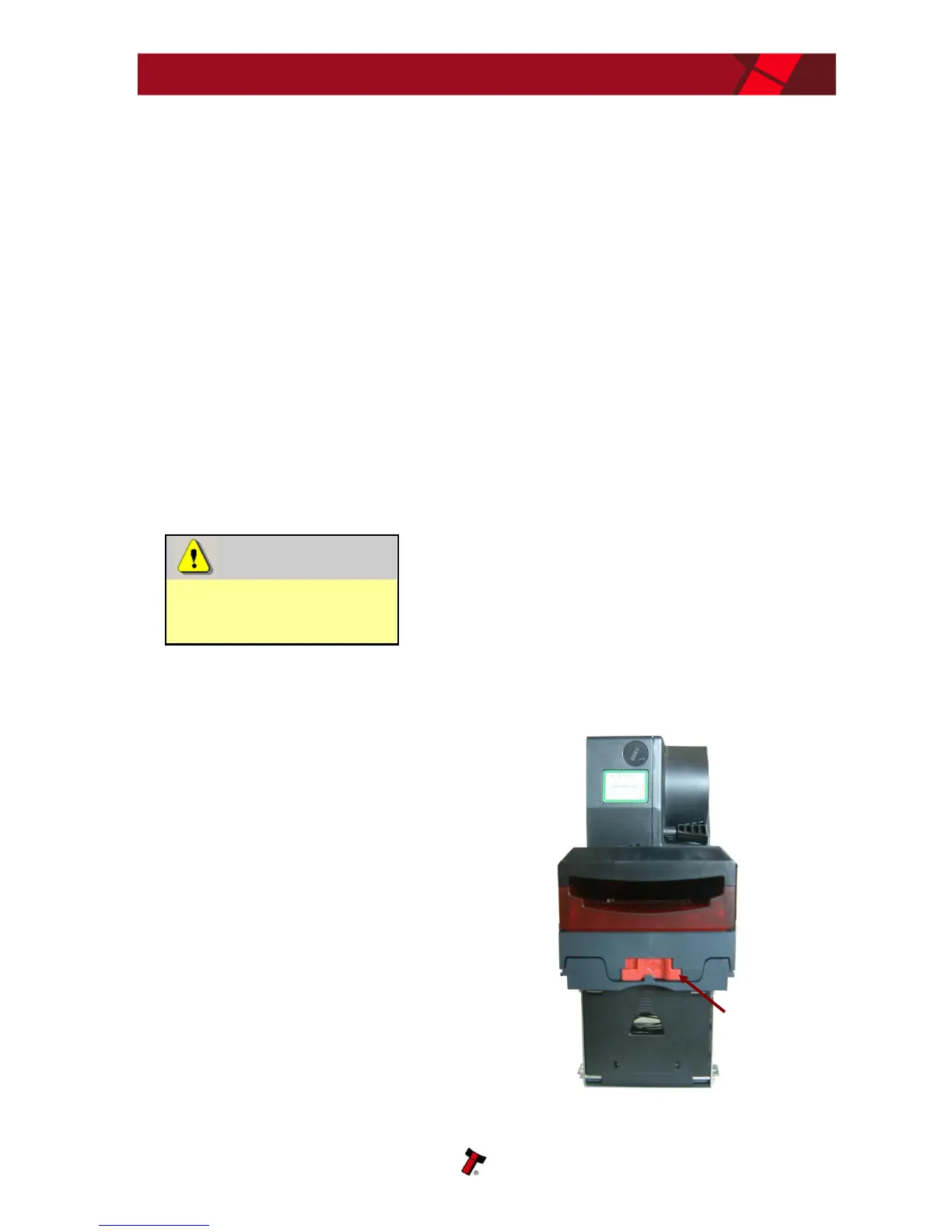

To clean the NV11, open the note

path by sliding the red release catch

on the front of the validator to the

left (as indicated in the picture) - this

will allow access to the lozenge and

note path

Loading...

Loading...