Thermal/Mechanical Reference Design

30 Dual-Core Intel® Xeon® Processor 5100 Series Thermal/Mechanical Design Guide

Once the T

CONTROL

value is determined as explained earlier, the DTS temperature

reading from the processor can be compared to this T

CONTROL

value. A fan speed

control scheme can be implemented as described in Table 2-7 without compromising

the long-term reliability of the processor.

There are many different ways of implementing fan speed control, including FSC based

on processor ambient temperature, FSC based on processor Digital Thermal Sensor

(DTS) temperature or a combination of the two. If FSC is based only on the processor

ambient temperature, low acoustic targets can be achieved under low ambient

temperature conditions. However, the acoustics cannot be optimized based on the

behavior of the processor temperature. If FSC is based only on the Digital Thermal

Sensor, sustained temperatures above T

CONTROL

drives fans to maximum RPM. If FSC is

based both on ambient and Digital Thermal Sensor, ambient temperature can be used

to scale the fan RPM controlled by the Digital Thermal Sensor. This would result in an

optimal acoustic performance. Regardless of which scheme is employed, system

designers must ensure that the Thermal Profile specification is met when the processor

Digital Thermal Sensor temperature exceeds the T

CONTOL

value for a given processor.

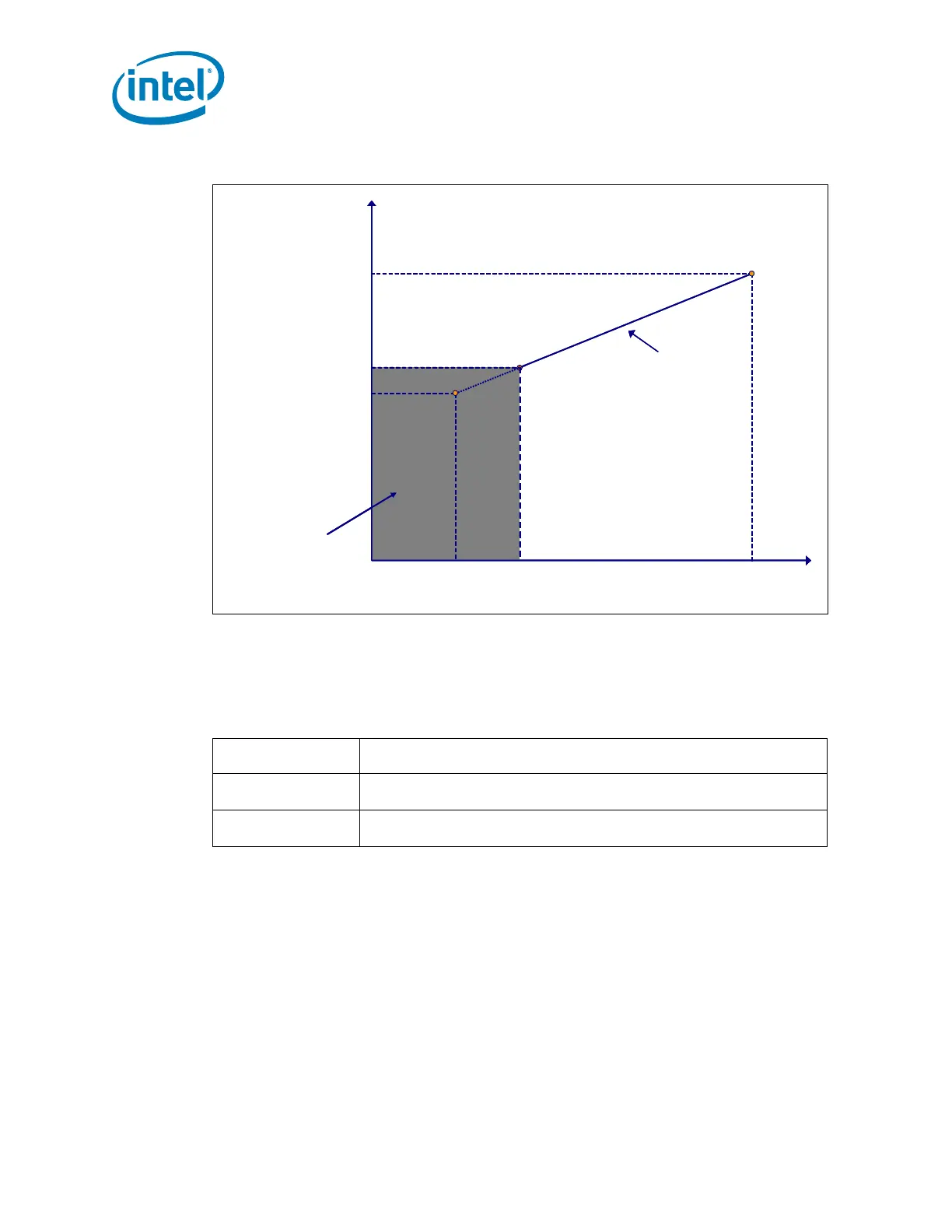

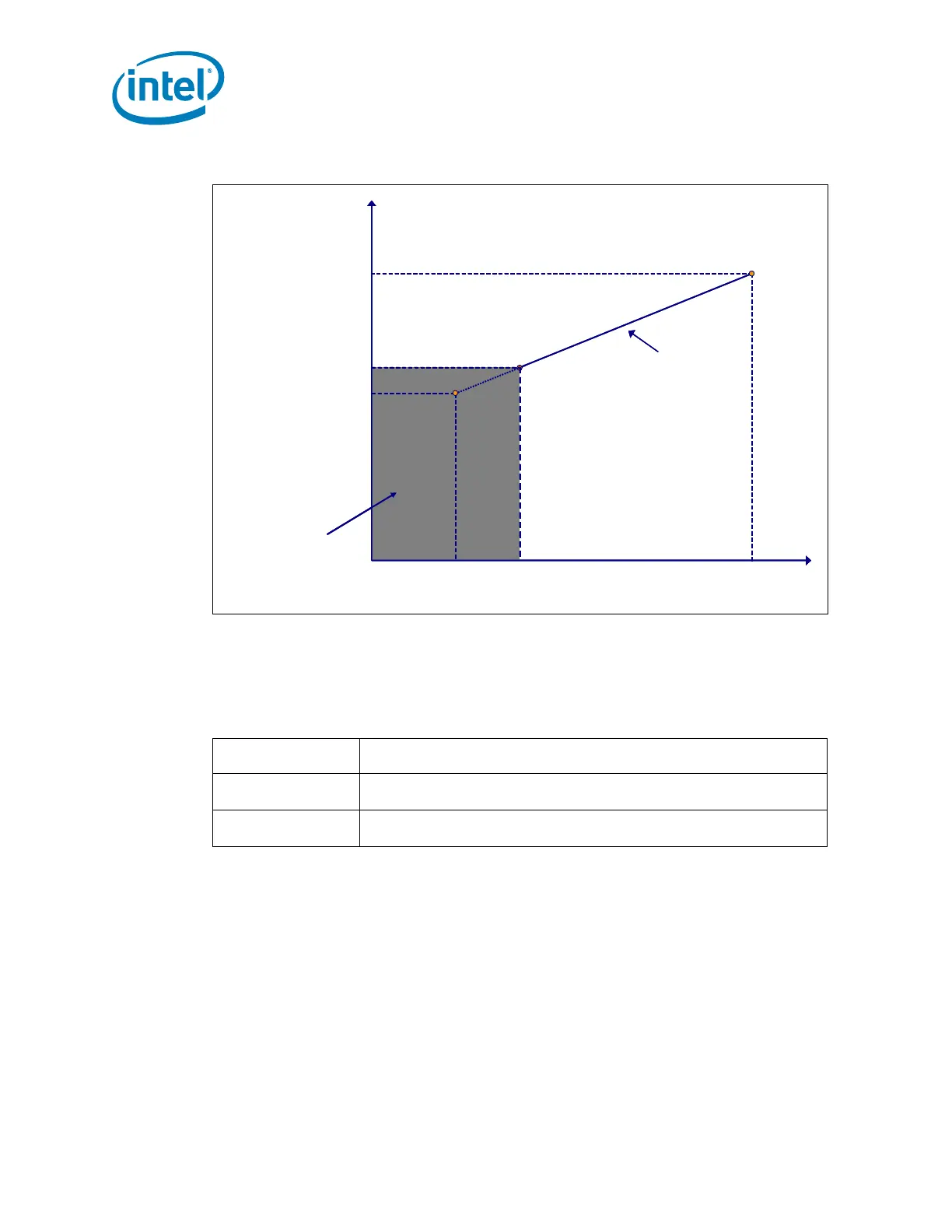

Figure 2-12. T

CONTROL

and Fan Speed Control

T

CASE

MAX

T

CASE

P

_PROFILE_MIN

T

CASE

MAX@

P

_PROFILE_MIN

Power

TDP

Thermal Profile

T

CASE

@DTS=

T

CONTROL

②

①

Fan Speed Control Region

T

CASE

MAX

T

CASE

P

_PROFILE_MIN

T

CASE

MAX@

P

_PROFILE_MIN

Power

TDP

Thermal Profile

T

CASE

@DTS=

T

CONTROL

②

①

Fan Speed Control Region

Table 2-7. Fan Speed Control, T

CONTROL

and DTS Relationship

Condition FSC Scheme

DTS≤ T

CONTROL

FSC can adjust fan speed to maintain DTS = T

CONTROL

(low acoustic region).

DTS>T

CONTROL

FSC should adjust fan speed to keep T

CASE

at or below the Thermal Profile

specification (increased acoustic region).

Loading...

Loading...