3 SET UP THE SPLICING SYSTEM

Belt Splicing System v.2.0

3-1

Avoid Injury.

Use caution when handling knives and

trim tools.

Contact with hot Heat Wand or stand

will cause skin burns; use caution.

Do NOT submerge equipment or

expose it to direct spray.

Always use ground fault protection/

residual current protection when

operating in damp or wet conditions.

Collect Needed Supplies

1. Bring Splicing System storage case and these

shop items to the conveyor.

• heat-resistant gloves and sleeves (rated

for continuous use up to 500°F (260ºC)

• safety glasses and cut-resistant gloves

• tape measure

• soft, clean, dry, oil-free cloths or paper

towels

• detergent (without ammonia or bleaches)

to remove used belt dirt and residue

• alcohol to sanitize and dry belt

• multiple F- or C-clamps

• spare two (2)-sided utility knife blades

2. Unload the Splicing System storage case

contents near required electric power and the

belt to be spliced.

3. Collect new sprockets (if you are installing

new belts) and any needed carryway and

returnway replacement components.

4. Ensure the facility temperature is above 40°F

(5°C) to produce proper splices. If splicing area

is below 40°F (5°C), see TROUBLESHOOT on

page 10-1.

Prepare the Conveyor

See the ThermoDrive® Belting Conveyor Belt-

ing Installation and Maintenance at the

Intralox website or contact Intralox for com-

plete assembly and disassembly instructions.

1. Disconnect power to the conveyor.

2. Remove or disable components as needed to

prevent accidental tensioning.

3. Remove components that may cause excess

backbends.

4. Replace worn components being careful not

to create drive bar snags.

5. Install new sprockets with new belting.

6. String the belt on the conveyor and follow

correct pulley wrap configuration. Avoid con-

veyor cross braces, legs, and other snags.

7. Trial-fit and mark the belt for length. Leave

enough catenary sag so the belt NEVER runs

under tension.

8. Place marked belt area or ends where the

Splicing System can be easily and safely used.

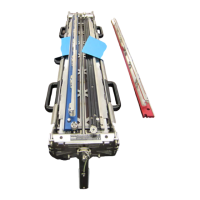

Request assistance when moving or

splicing with the 42" Splicing System.

SET UP THE SPLICING SYSTEM

3

Loading...

Loading...