14 S8126 BELT SPECIFICS

Belt Splicing System v.2.0

14-5

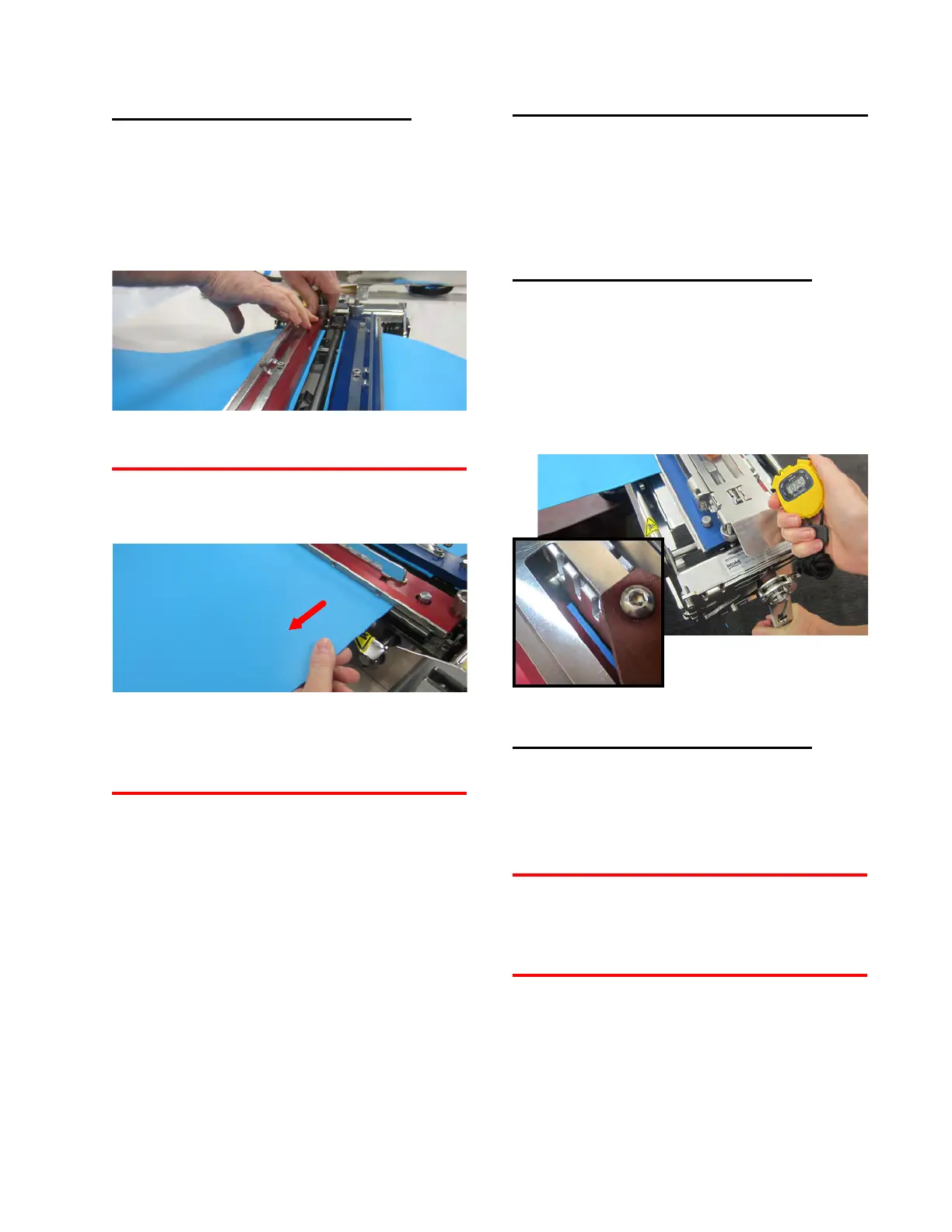

Hold the Cut Guides when

Fully Tightening Thumb Knobs

Hold the Cut Guides against the Belt Tabs,

while finger-tightening the thumb knobs evenly

at each belt edge.

Figure 14L: Clamp belt edges securely

Check for secure clamping by tugging gently

on the belt edges just before splicing.

If the belt moves when pulled, consider adding

an additional tape layer to the tape shims. Do

not add so much that belt drive bars cannot

engage the Grooved Decks.

Splice the Belt Ends

Because S8126 belting is difficult to clamp

securely, even normal clamping force can shift

the belt ends during splicing. When splicing

belt ends, include these steps in the procedure.

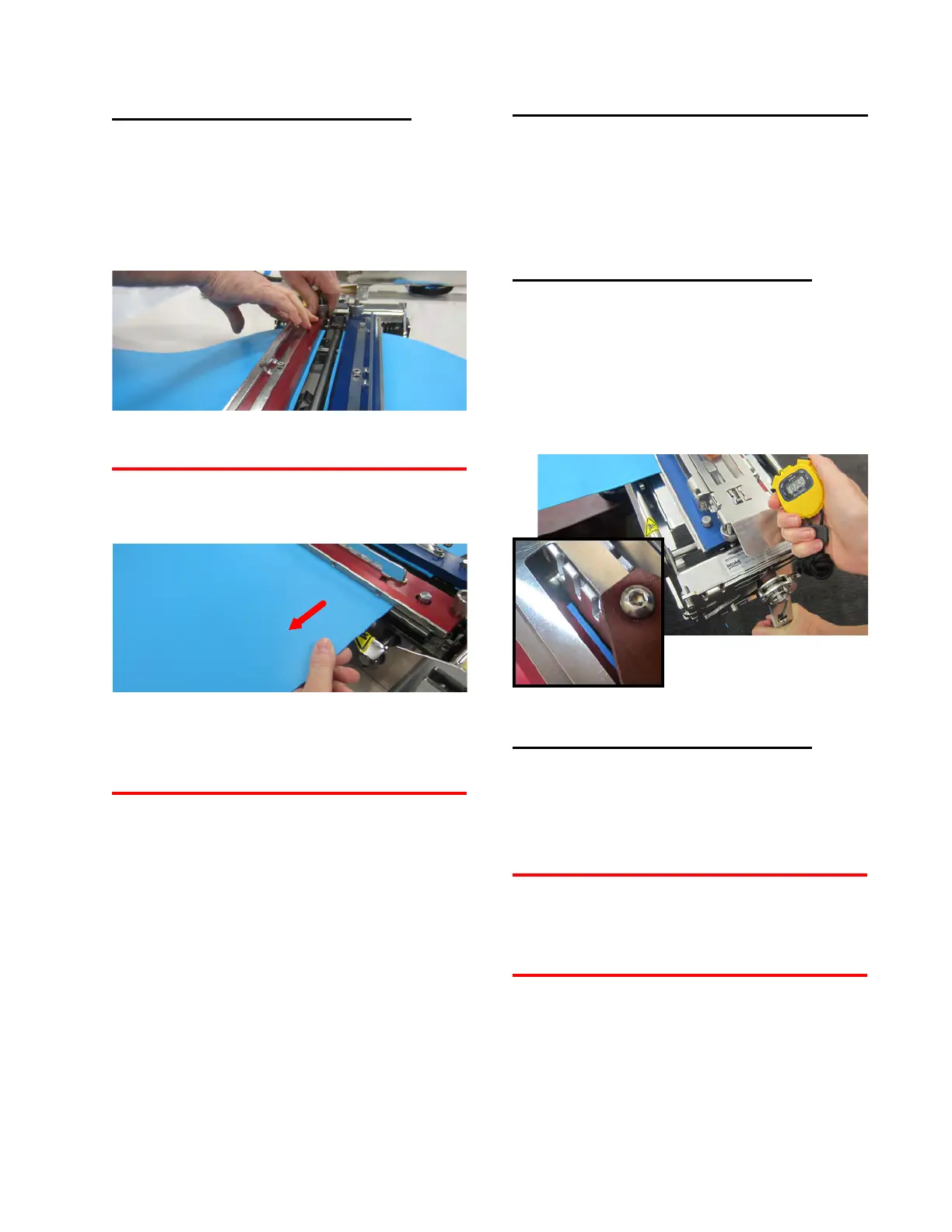

Control the Crank Handle

for 25 Seconds of Melting

Turn the Crank Handle gradually so melting

belt ends maintain contact with the Heat Wand

for the first 25 seconds, then lock the Clamping

Fixture closed.

Figure 14M: Maintain control of the Crank Handle

Close Decks Gently for Cooling

When removing the Heat Wand, control the

Crank Handle to close the Clamping Fixture

completely, but gently.

Normal clamping force can

cause belt end misalignment. Maintain control

of Crank Handle at all times.

Loading...

Loading...