5 ALIGN AND SECURE BELT ENDS

Belt Splicing System v.2.0

5-1

Avoid Injury.

Keep hands and fingers clear of Frame

edge when opening the Clamping

Fixture.

Contact with hot Heat Wand or Stand

will cause skin burns; use caution.

Prepare to Align

Ensure these requirements are met before align-

ing belt ends.

• The belt is strung on the conveyor.

• The belt is following the proper belt path.

• The belt ends are on the carryway.

• The Clamping Fixture is stable or secured

on the conveyor frame or platform under the

conveyor belt.

Align Belt Ends

These instructions provide the

most common cutting procedures.

If you are aligning S8126 belt ends, a belt with

troughing grooves, or a belt with nubs, see

SPECIAL PROCEDURES.

1. Open the Clamping Fixture fully.

2. Clear any dust, debris, or residue from the

Grooved Deck tops and edge.

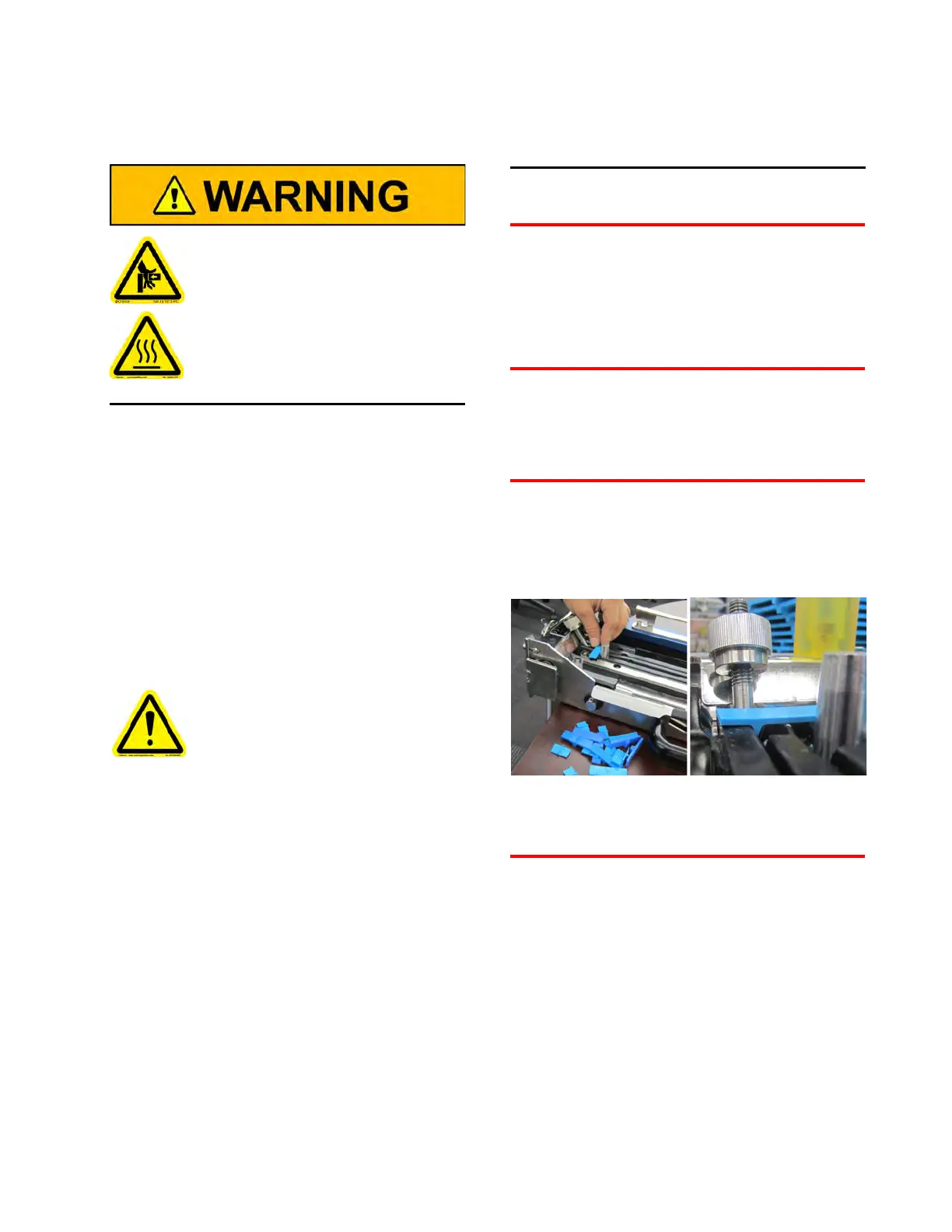

The following extra step helps equalize the

clamping pressure across the belt ends.

Gather four (4) Belt Tabs that match the belt

series and style you are splicing.

Place one Belt Tab at each Grooved Deck end

between the Locating Pin and the Pivoting

Stud. Ensure the drive bars engage the grooves.

Keep hands and fingers clear of fixture

frame when opening the Clamping

Fixture.

ALIGN AND SECURE BELT ENDS

5

Loading...

Loading...