5 ALIGN AND SECURE BELT ENDS

Belt Splicing System v.2.0

5-5

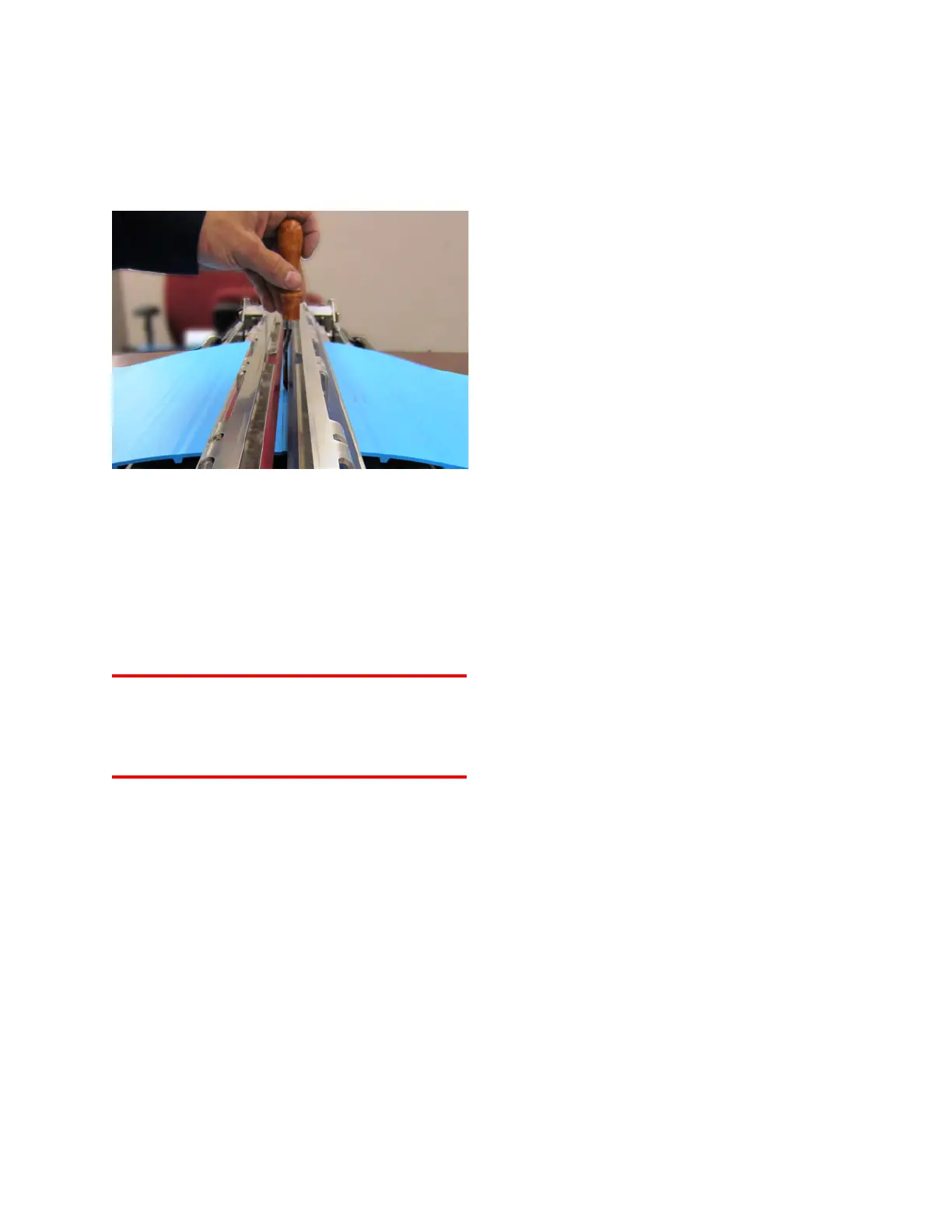

Belt end top surfaces are flush within 1/

64" (0.5 mm). This is most easily assessed

by sliding the Skiver tip across the belt

ends to ‘feel’ for an uneven surface.

Figure 5J: Inspect belt surface vertical alignment

FAIL: If belt ends do NOT meet these require-

ments, troubleshoot until requirements are met.

See TROUBLESHOOT on page 10-1.

PASS: When belt ends meet all requirements,

fully open the Grooved Decks to splice the belt.

See SPLICE THE BELT on page 6-1.

Once belt ends are aligned and secured, do not

allow the Clamping Fixture to close suddenly

or with force.

Loading...

Loading...