14 S8126 BELT SPECIFICS

14-4

Belt Splicing System v.2.0

Align & Secure Belt Ends

For best results, use a 24" Splicing System and

align belts with drive bars face down.

To align and secure S8126 belt ends for splic-

ing, include these steps in the procedure.

Remove any Belt Tension

To minimize pull on the belt ends, ensure ade-

quate belt slack is provided on each side of the

Clamping Fixture.

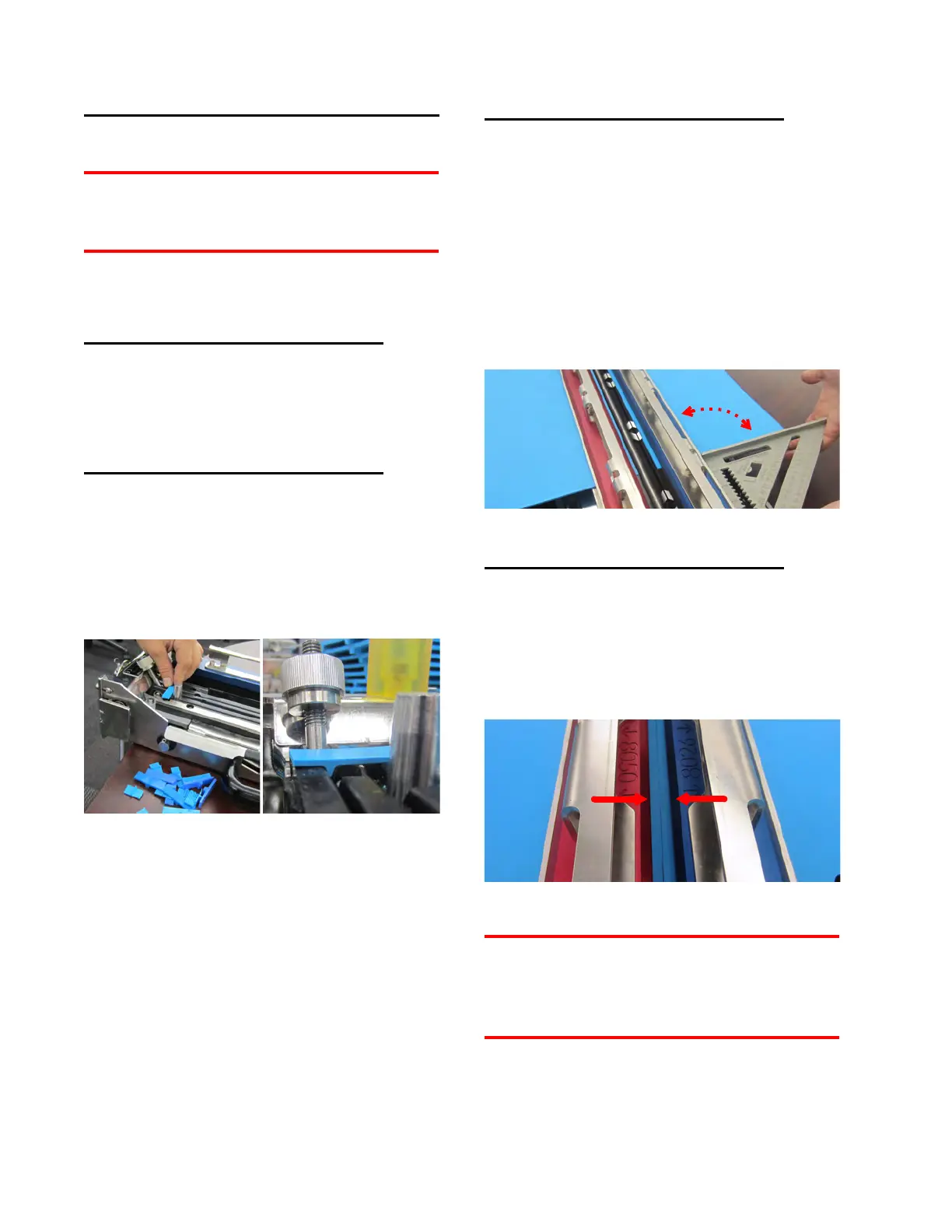

Check for Shims and Belt Tabs

1. Ensure tape shims are on belt smooth edges.

2. Ensure there is one (1) Belt Tab between

each Pivoting Stud and Locating Pin. If Belt

Tabs are missing, see Use Thin Belt Tabs to

Secure Belt Ends on page 14-2.

Figure 14I: Place thin Belt Tabs on Grooved Decks

Repeatedly Inspect Alignment

Check Parallel Alignment: Ensure the belt ends

are visibly parallel to the Grooved Deck when

first placing belts, aligning belt ends, and just

before splicing.

Check Perpendicular Alignment: Use a square

edge to ensure each belt edge is perpendicular

to the Cut Guide when placing belts, aligning

belt ends, and just before splicing.

Figure 14J: Inspect with square edge

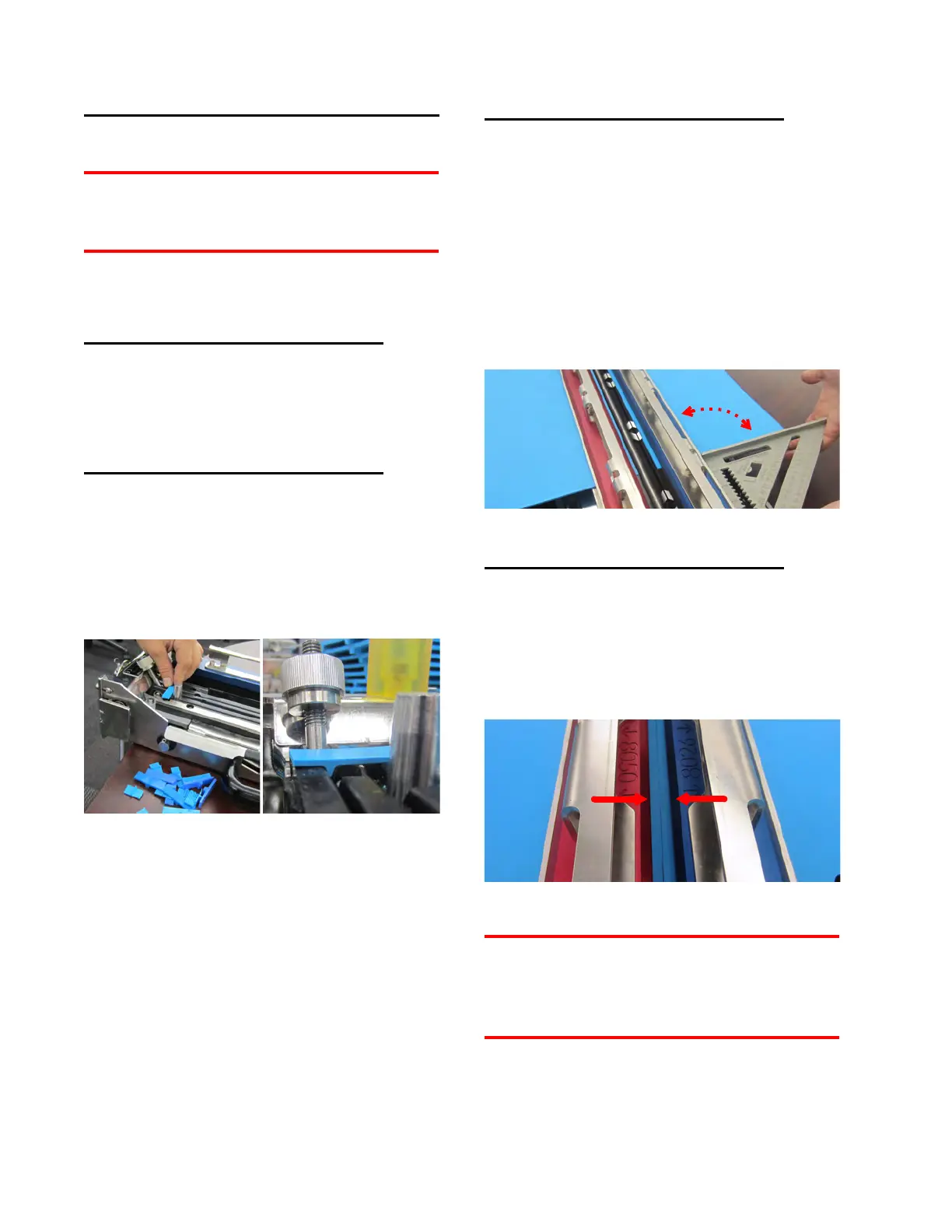

Control Crank Handle During

Alignment

Gently open and close the Clamping Fixture to

inspect belt end alignment. Do not allow belt

ends to touch.

Figure 14K: Inspect touching ends

Normal clamping force can

cause belt end misalignment. Maintain control

of Crank Handle at all times.

Loading...

Loading...