DA180 series basic AC servo drive Fault handling

-259-

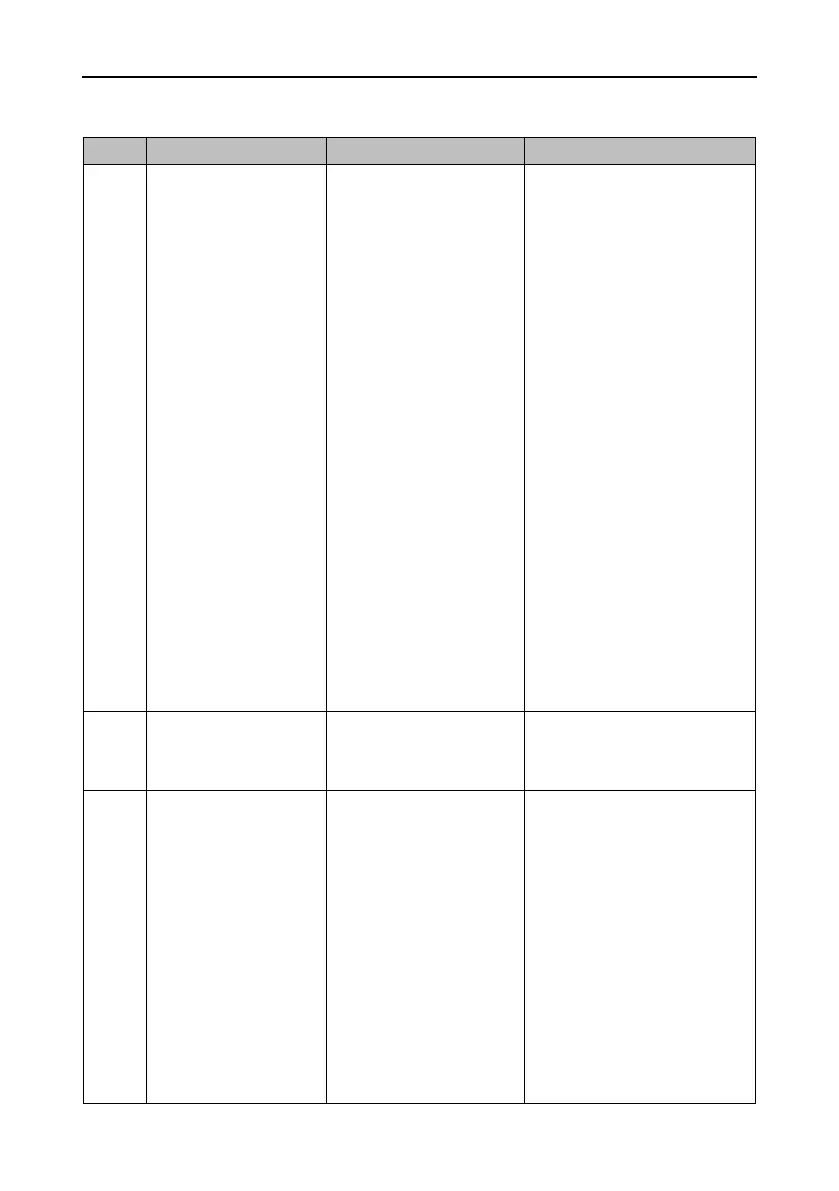

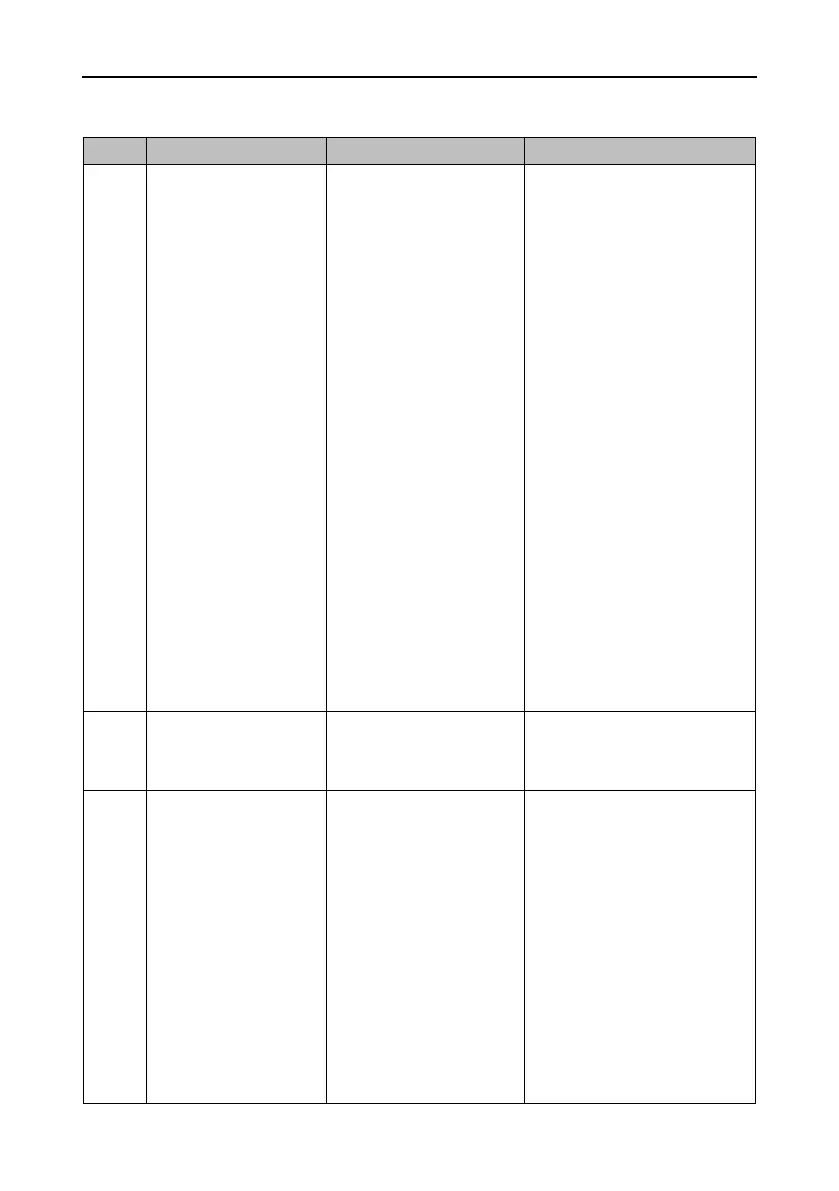

9.1 Servo drive faults and workarounds

The drive actual output

current exceeds the

specified value.

1. Drive fault (such as drive

circuit or IGBT fault).

2. Drive cables U, V, and W

are short connected, or drive

cables are grounded or

contacted improperly.

3. The motor breaks down.

4. Drive cables U, V, and W

are connected in reverse

phases.

5. Improper parameter

settings cause system

divergence.

6. The ACC/DEC time in the

start or stop process is too

short.

7. Instantaneous load is too

heavy.

1. Remove the motor cables and

then enable the drive. If the fault

persists, replace the drive.

2. Ensure the motor cables and

wiring are in good conditions.

3. Reduce the settings of P0.10

and P0.11 to reduce the

maximum output torque.

4. Increase the ACC/DEC time.

5. Replace the drive with a new

one with greater power.

6. Replace the motor.

Brake pipe fault (for

models of 7.5kW or

above)

The drive actual output

current exceeds the

specified value.

1. Drive fault (such as drive

circuit or IGBT fault).

2. Drive cables U, V, and W

are short connected, or drive

cables are grounded or

contacted improperly.

3. The motor breaks down.

4. Drive cables U, V, and W

are connected in reverse

1. Remove the motor cables and

then enable the drive. If the fault

persists, replace the drive.

2. Ensure the motor cables and

wiring are in good conditions.

3. Reduce the settings of P0.10

and P0.11 to reduce the

maximum output torque.

4. Increase the ACC/DEC time.

5. Replace the drive with a new

one with greater power.

6. Replace the motor.

Loading...

Loading...