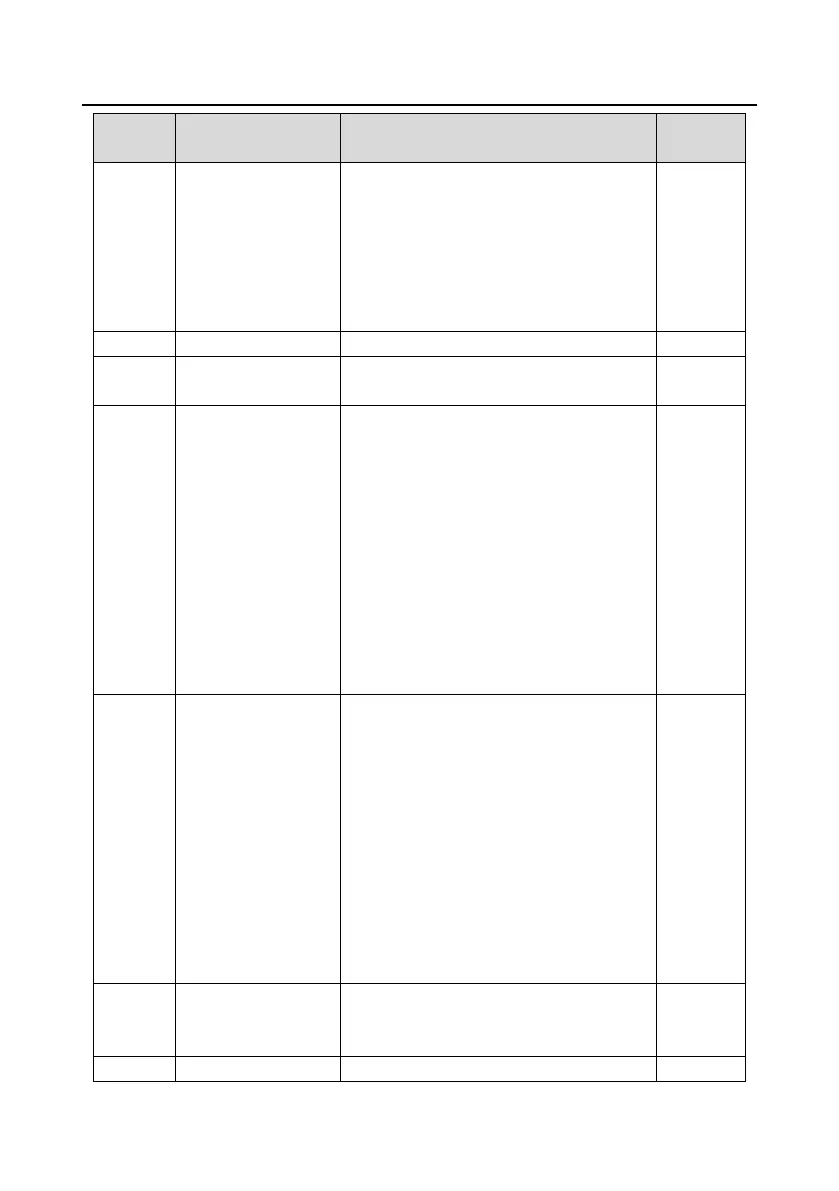

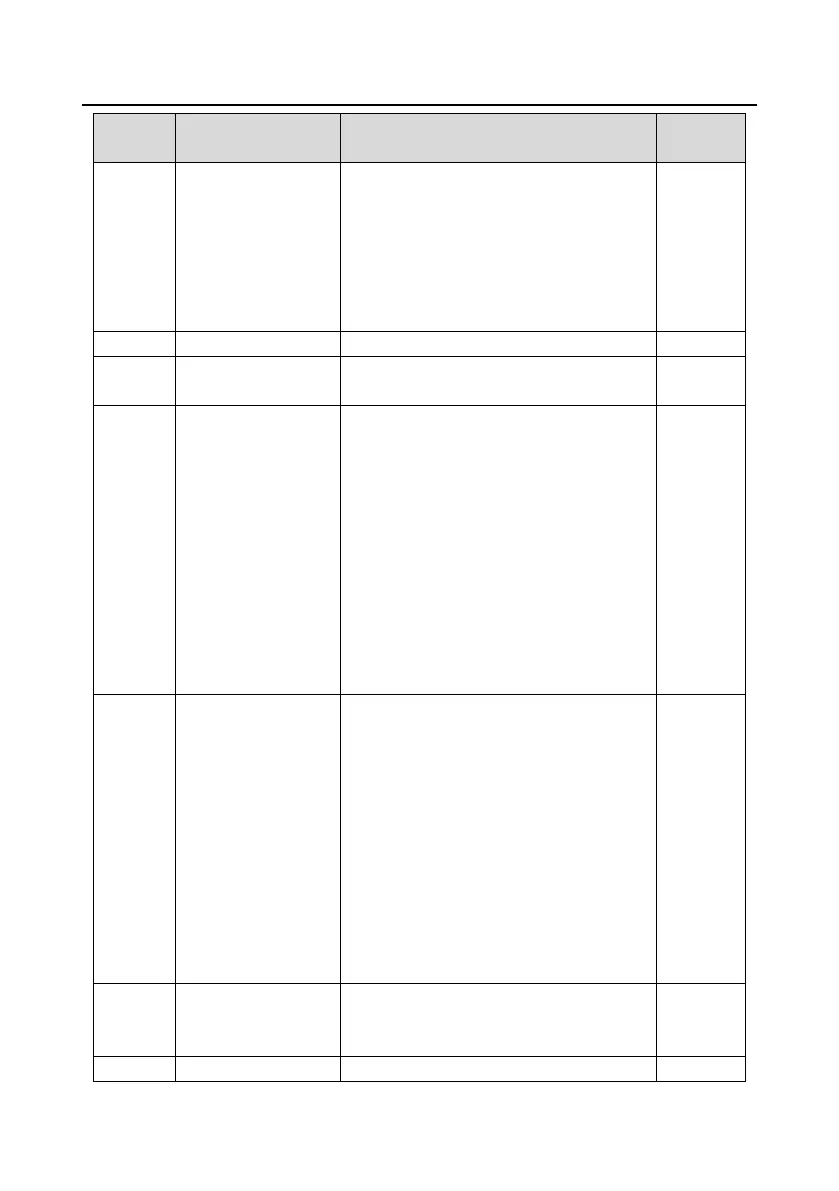

Goodrive35 Series Closed-loop Vector Control VFD Basic operation instruction

150

Detailed instruction of parameters

7: Modbus communication setting torque (the

same as above)

8: PROFIBUS/CANopen communication

setting torque (the same as above)

9: Ethernet communication setting torque (the

same as above)

10: Reserved

-300.0%–300.0% (rated current of the motor)

Torque reference filter

time

Upper frequency of

forward rotation in

vector control

0: Keypad (P03.16)

1: AI1 (100% corresponds to max. frequency)

2: AI2 (the same as above)

3: AI3 (the same as above)

4: Pulse frequency HDI (the same as above)

5: Multi-step (the same as above)

6: Modbus communication (the same as

above)

7: PROFIBUS/CANopen communication (the

same as above)

8: Ethernet communication (the same as

above)

Upper frequency of

reverse rotation in

vector control

0: Keypad (P03.17)

1: AI1 (100% corresponds to max. frequency)

2: AI2 (the same as above)

3: AI3 (the same as above)

4: Pulse frequency HDI (the same as above)

5: Multi-step (the same as above)

6: Modbus communication (the same as

above)

7: PROFIBUS/CANopen communication (the

same as above)

8: Ethernet communication (the same as

above)

Keypad setting for

upper frequency of

forward rotation

0.00 Hz–P00.03 (max. output frequency)

0.00 Hz–P00.03 (max. output frequency)

Loading...

Loading...