Goodrive35 Series Closed-loop Vector Control VFD Extension card

251

21: MSB of position reference (signed

digit)

22: LSB of position reference (unsigned

digit)

23: MSB of position feedback (signed digit)

24: LSB of position feedback (unsigned

digit)

25: State words

PKW area (parameter identification marks PKW1-value area). PKW area describes treatment of

parameter identification interface, PKW interface is a mechanism which determine parameters

transmission between two communication partners, such as reading and writing parameter values.

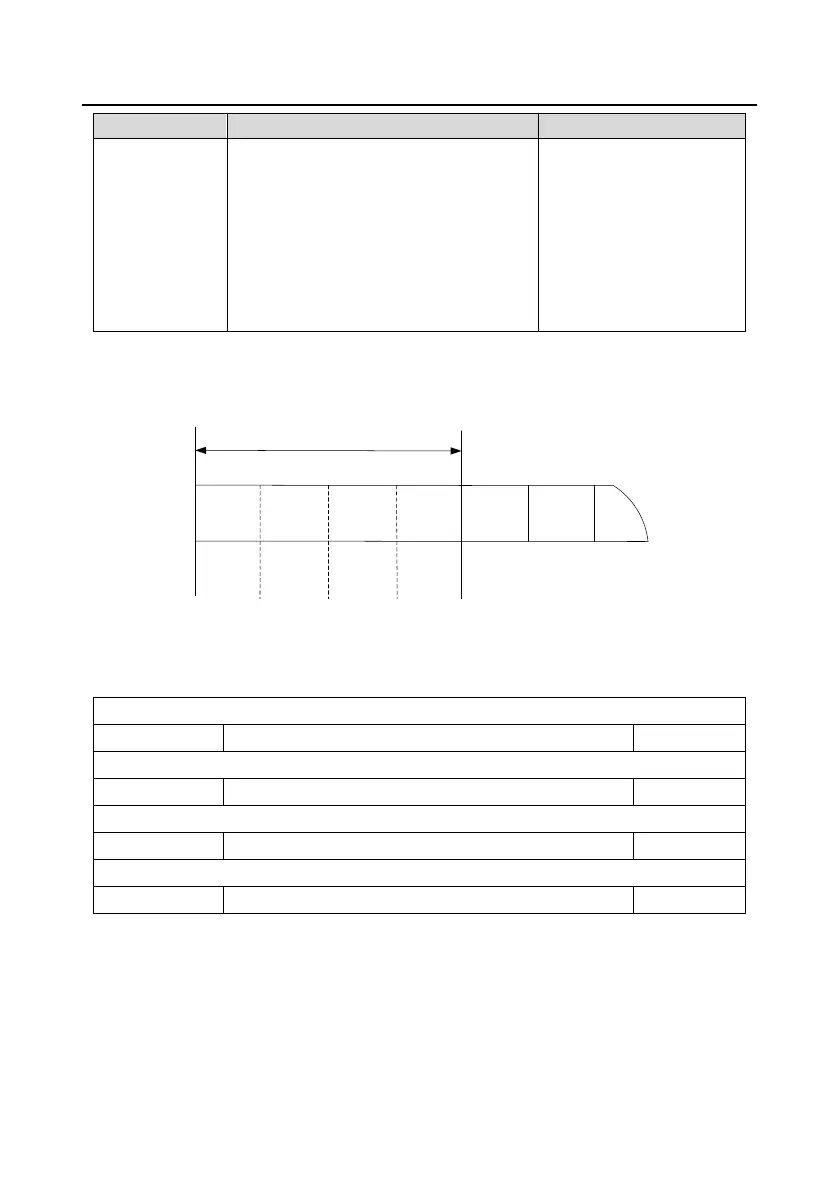

Structure of PKW zone (PWK)

Process data

Parameters

Parameter

address

Request

mark

Response

mark

Fault code

PKW1 PKW2

PKW3 PKW4

CW

SW

PZD2

PZD2

……

Parameter identification zone

In the process of periodic PROFIBUS-DP communication, PKW area is composed of four words (16

bit), each word is defined as follows:

The first word PKW1 (16 bit)

Task or response identification marks

The second word PKW2 (16 bit)

The third word PKW3 (16 bit)

Parameter value (high word) or return error code value

The fourth word PKW4 (16 bit)

Parameter value (low word)

Note: If the master requests one parameter value, the value of PKW3 and PKW4 will not be valid.

Task requests and responses: When passing data to slave machine, master machine use request

label while slave machine use response label to positive or negative confirmation. The following table

lists the request/response functional.

The definition of task logo PKW1 is as follows:

Loading...

Loading...