6A – 40 GENERAL ENGINE MECHANICAL

4) After pressing in the oil seal, check the measurement

of the oil seal.

Standard mm (in)

0.6 - 1.2 (0.024 - 0.047)

3a. Timing Belt and Pulley (Belt Drive Model)

7) Camshaft Timing Pulley

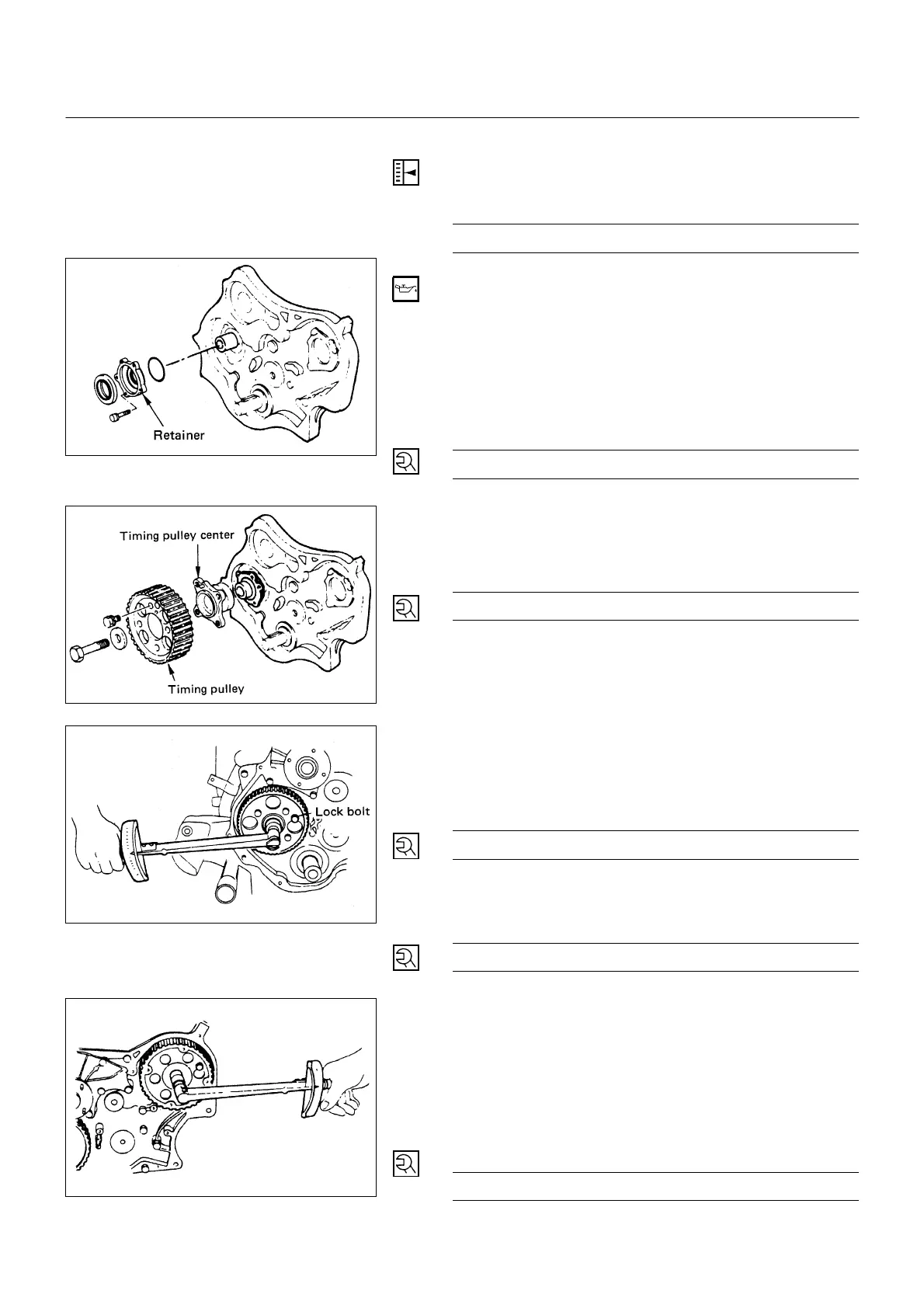

• Apply engine oil to the oil seal lip portion of the oil seal

retainer.

• Apply the recommended liquid gasket or its equivalent

to the retainer.

• Install the oil seal retainer to the cylinder body.

• Tighten the retainer bolts to the specified torque.

Oil Seal Retainer Bolt Torque N∙m (kg∙m/lb∙ft)

19 (1.9/14)

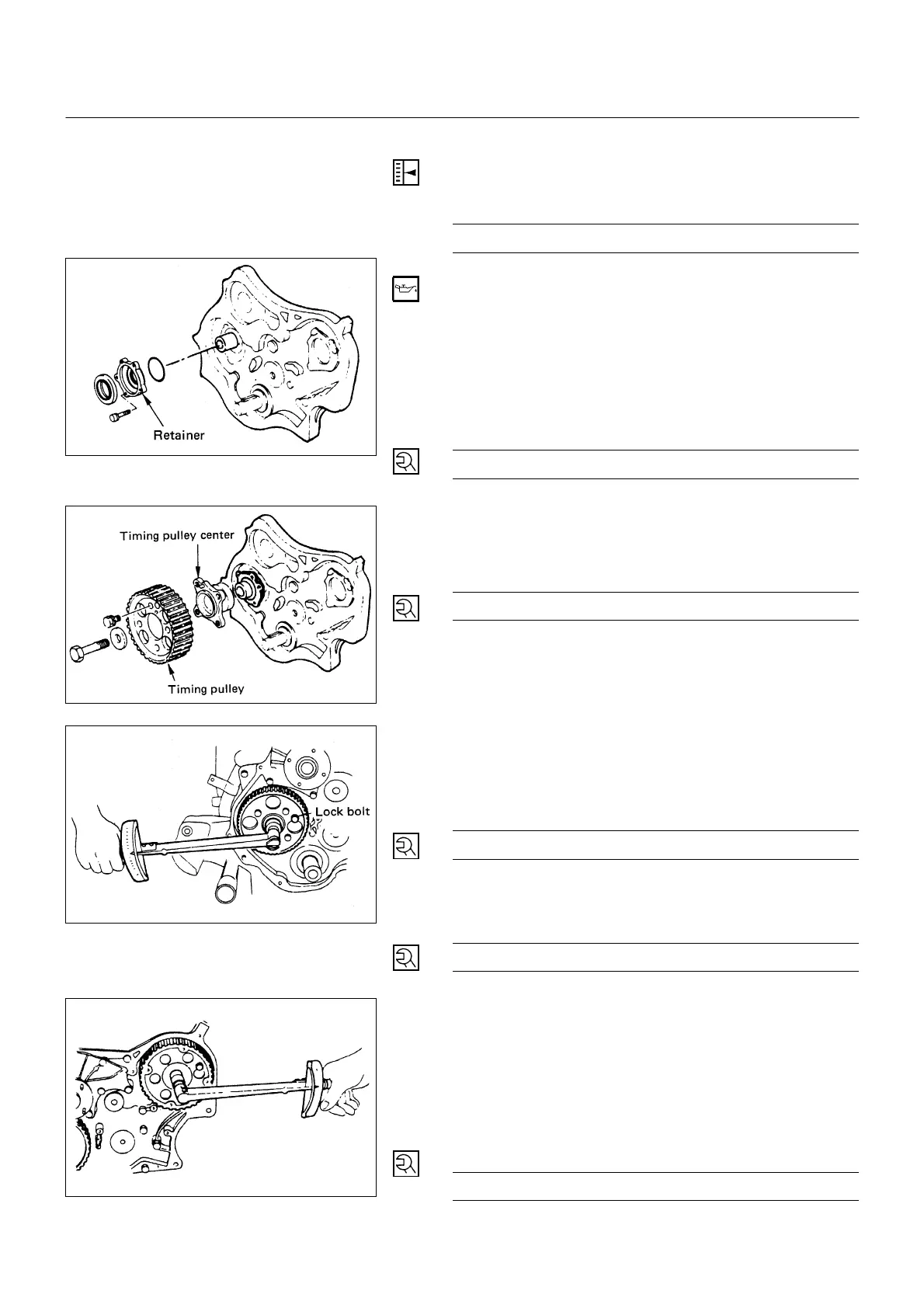

• Align the camshaft timing pulley center with the

camshaft key.

• Tighten the timing pulley bolts to the specified torque.

Timing Pulley Bolt Torque N∙m (kg∙m/lb∙in)

8 (0.8/69)

• Prevent the camshaft from turning when tightening the

timing center bolt.

• Tighten the timing pulley center bolt to the specified

torque.

Center Bolt Torque N∙m (kg∙m/lb∙ft)

64 (6.5/47)

• Install the crank pulley.

• Install the idle pulley and idler pulley.

N∙m (kg∙m/lb∙ft)

76 (7.8/56)

• Install the injection pump assembly and install timing

pulley.

• Align the timing pulley with the pump shaft key.

• Install the stopper bolt to the timing pulley.

This will prevent the timing pulley from moving.

• Tighten the timing pulley nut to the specified torque.

Injection Pump Timing Pulley Nut Torque

N∙m (kg∙m/lb∙ft)

64 (6.5/47)

• Remove the stopper bolt from the injection timing.

6A-40-1.tif

6A-40-2.tif

6A-40-3.tif

6A-40-4.tif

Loading...

Loading...