6A – 42 GENERAL ENGINE MECHANICAL

NOTE:

Timing belt tension must be adjusted.

Failure to adjust the timing belt tension will result in

timing belt damage.

*

Tighten the tension bolt.

11

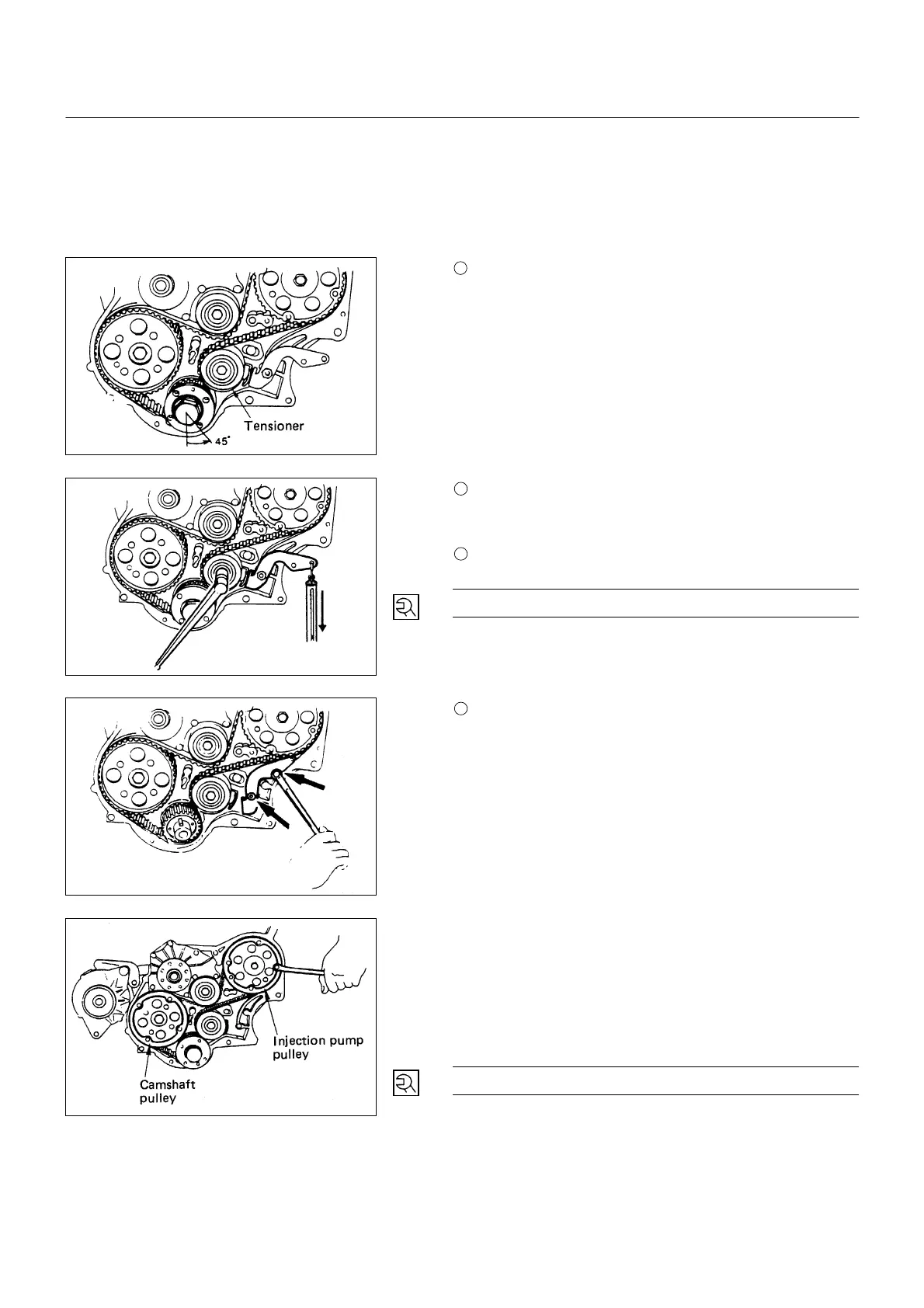

Rotate the crankshaft 45 degrees counterclockwise.

NOTE:

Never rotate the crankshaft clockwise when adjusting

the timing belt.

12

Readjust the timing belt tension.

Refer to Step 9

This will remove any remaining timing belt slack.

13

Tighten the tensioner bolt to the specified torque.

Tensioner Bolt Torque N∙m (kg∙m/lb∙ft)

76 (7.7/56)

14

Tighten the tension adjusting lever nut and bolt.

NOTE:

If on-vehicle timing belt replacement is performed, the

crankshaft must not be allowed to turn.

If the crankshaft is allowed to turn, piston and valve

damage will result.

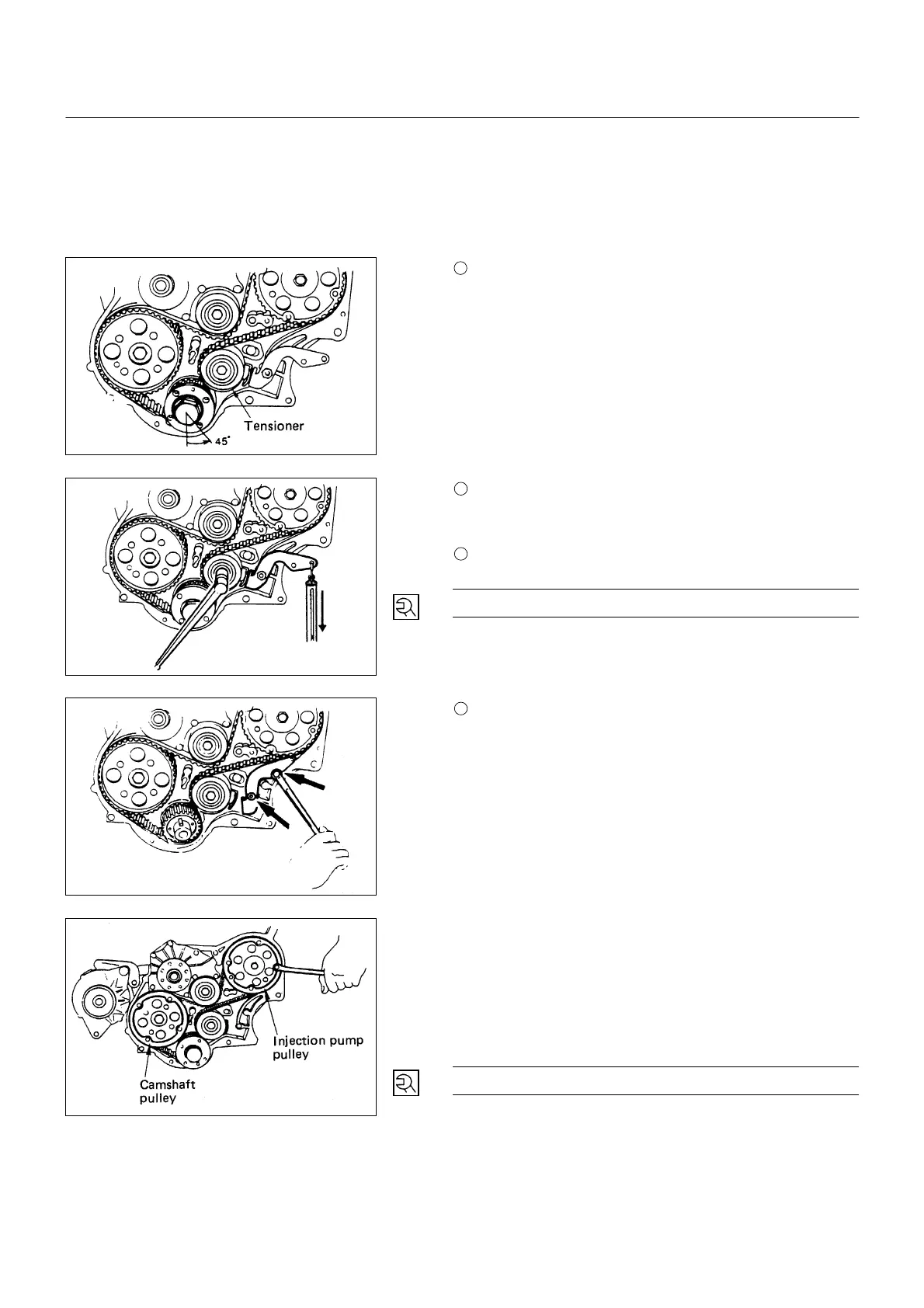

5) Flange: Camshaft Pulley

4) Flange: Injection Pump Pulley

• Install the timing pulley flange to the camshaft and

injection pump timing pulley.

• Tighten the timing pulley flange bolts to the specified

torque.

Timing Pulley Flange Bolt Torque N∙m (kg∙m/lb∙ft)

19 (1.9/14)

6A-42-2.tif

6A-42-3.tif

6A-42-4.tif

6A-43-1.tif

Loading...

Loading...