FORM 160.77-O2

ISSUE DATE: 11/15/2011

SECTION 1 - YKEP CHILLER OVERVIEW

JOHNSON CONTROLS

15

1

ANTI-SURGE, PRV

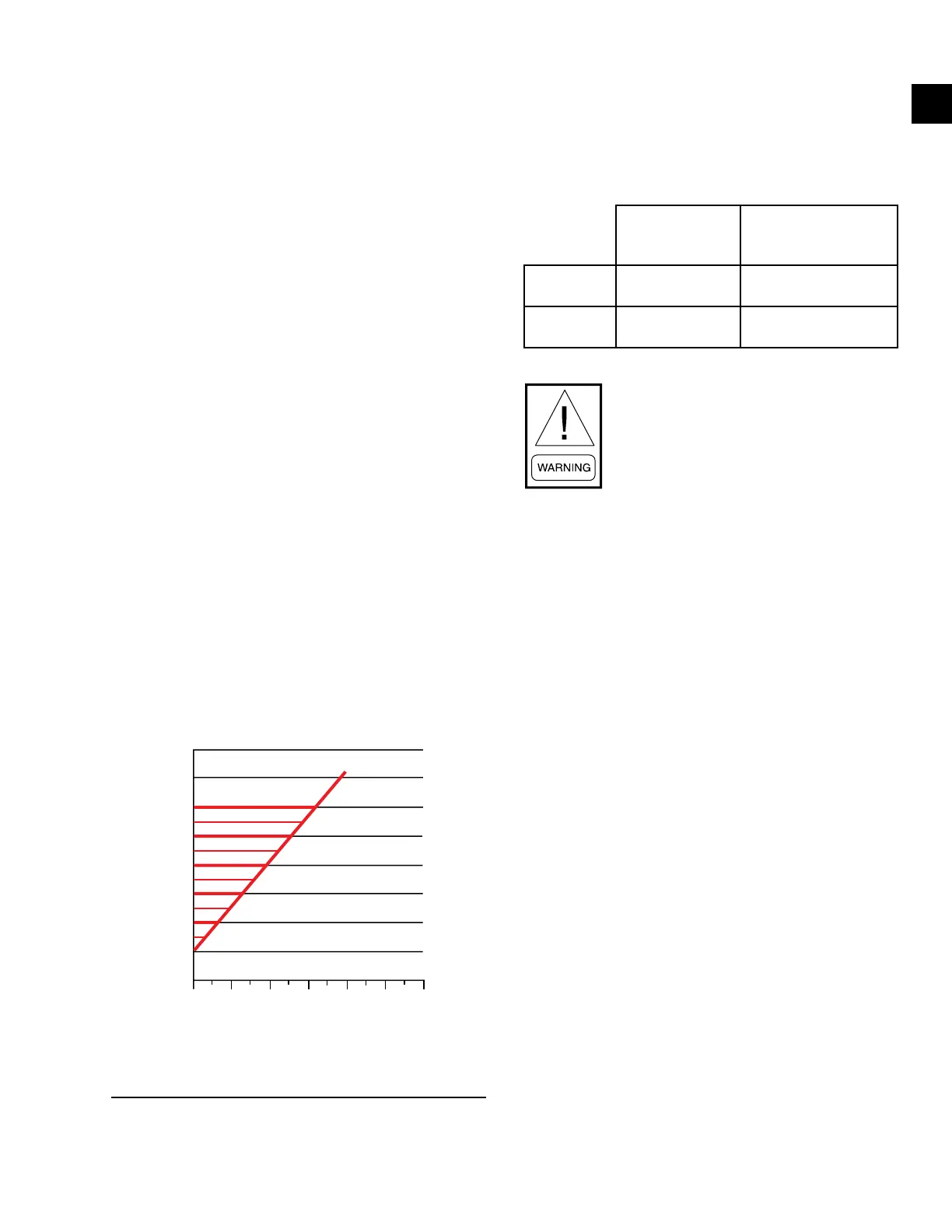

Keeping the compressor out of surge is the function

of the anti-surge subsystem. The anti-surge system is

based on a straight-line approximation of the compres-

sor surge curve (Figure 6 on Page 15).

The anti-surge line is biased to the right of the actual

surge line. When the compressor needs to move left on

the map, and move less mass flow, the vanes can only

be reduced so far, before a lack of mass flow causes

a surge condition. The anti-surge system supplements

mass flow to the compressor by using the Hot Gas By-

pass valve. This allows the chiller to be unloaded with-

out surge.

Once the anti-surge system has been set for the maxi-

mum head condition, and the minimum head condi-

tion, the compressor is restricted from surge. The point

represented by the intersection of VPD1 and MVP1 is

the worst case operating condition of the compressor,

with high head and low load. The other condition that

defines the anti-surge line is at low head and low load,

represented by the intersection of VPD2 and MVP2.

The shaded area of the left side of the map is the surge

area.

The vanes cannot close more than a given percentage

for a given head condition, defined by this line. As the

capacity control system unloads the chiller, the Hot

Gas Bypass valve is opened proportionally to maintain

stable operation and control the process.

H

E

A

D

200

150

100

50

0

0 25 50 75 100

MVP2 MVP1

% VANES

VPD1

x

VPD2

FIGURE 6 - SYSTEM ANTI-SURGE MAP

LD15231

Anti-Surge (PRV) Calculation

The anti-surge tuning values are based on estimated

part load conditions and minimum vane signals re-

quired at these conditions to prevent unstable opera-

tion (surging):

Compressor

Differential

(Head) Pressure

Minimum PRV Signal

Setpoint for

Stable Operation

High Head

(PD1)

70 psid MVP1 = 8% Open

Low Head

(PD2)

30 psid MVP2 = 2% Open

It is very important that this control be

adjusted to suit chiller operating condi-

tions to achieve maximum efciency of

operation.

Anti-Surge (PRV) Tuning

• With the chiller running in automatic, take the

condensing conditions to the highest inlet tem-

perature attainable in the system (without tripping

on high discharge pressure). Increase tower inlet

temperature or reduce tower ow.

• At the highest condensing temperature, start re-

ducing the load on the chiller, by reducing the

ow, or decreasing the inlet temperature. This

will cause the capacity control system to back the

vanes in an unload sequence.

• If the chiller surges before the Hot Gas valve be-

gins to open, then the anti-surge line must move

right on the map.

• If the chiller never surges down to minimum load,

then the anti-surge parameters are adequate for

protection, but may not be most efcient.

• During the unload sequence, record the operating

head as VPD1.

• Increasing and decreasing the parameter MVP1

will move the anti-surge line right and left on the

map. Listen for a surge, and move the anti-surge

line right several percent, to increase refrigerant

ow, by supplementing hot gas.

• Repeat the procedure for low head operation.

• At the lowest condensing temperature, start reduc-

Loading...

Loading...