FORM 160.77-O2

ISSUE DATE: 11/15/2011

SECTION 1 - YKEP CHILLER OVERVIEW

JOHNSON CONTROLS

9

1

of the mass owing through the primary and in-

creasing chiller capacity. Upon unloading, when

the economizer compressor PRV closed switch is

activated, signifying the economizer compressor

is completely unloaded, or the economizer satu-

ration temperature is 0.5 Degrees F above what

the target saturation temperature would be for

economizing mode, the economizer compressor

switches back to economizing operation. Then

the primary compressor control returns to fol-

lowing the chiller programmed leaving chilled

liquid temperature and the economizer compres-

sor is following its target economizer pressure as

described in (2) above.

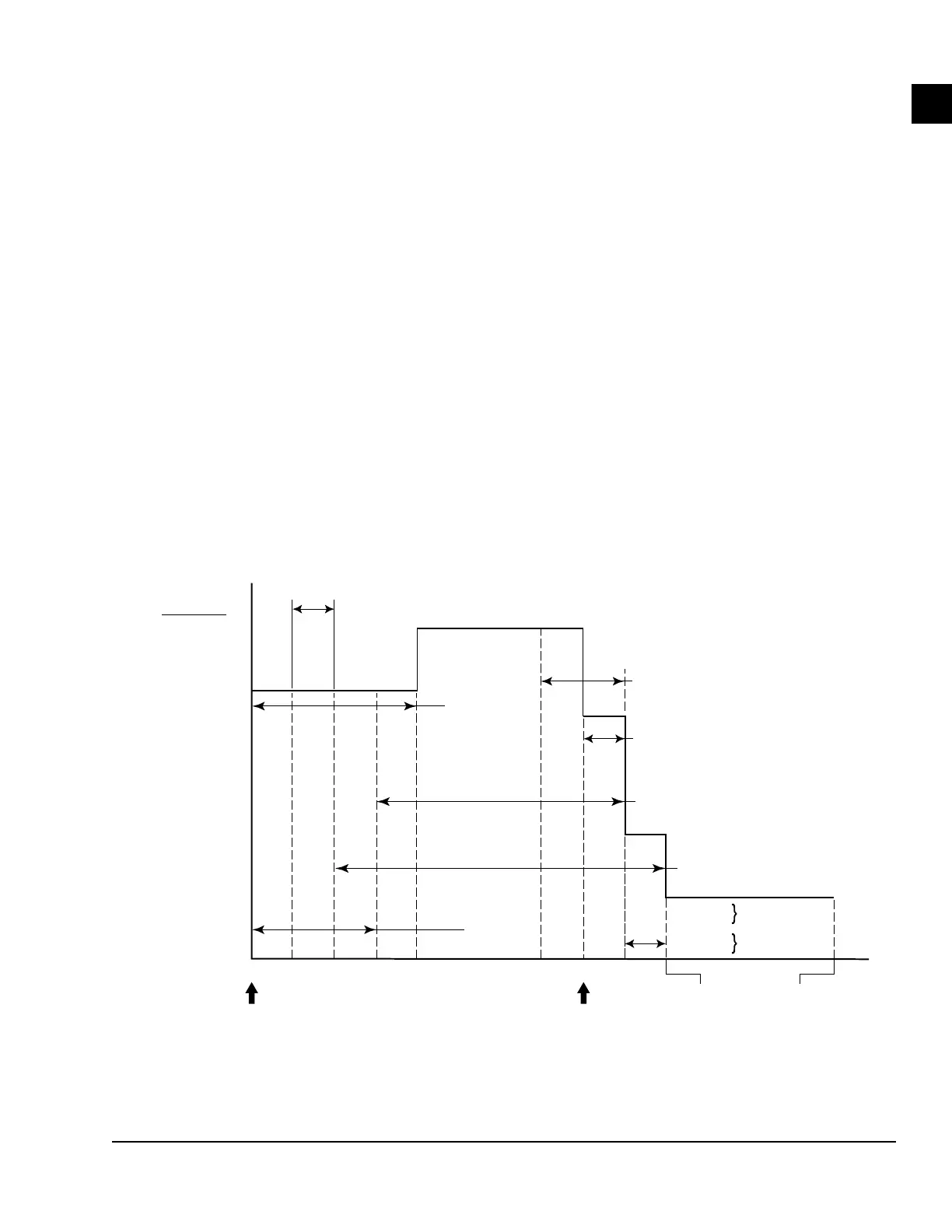

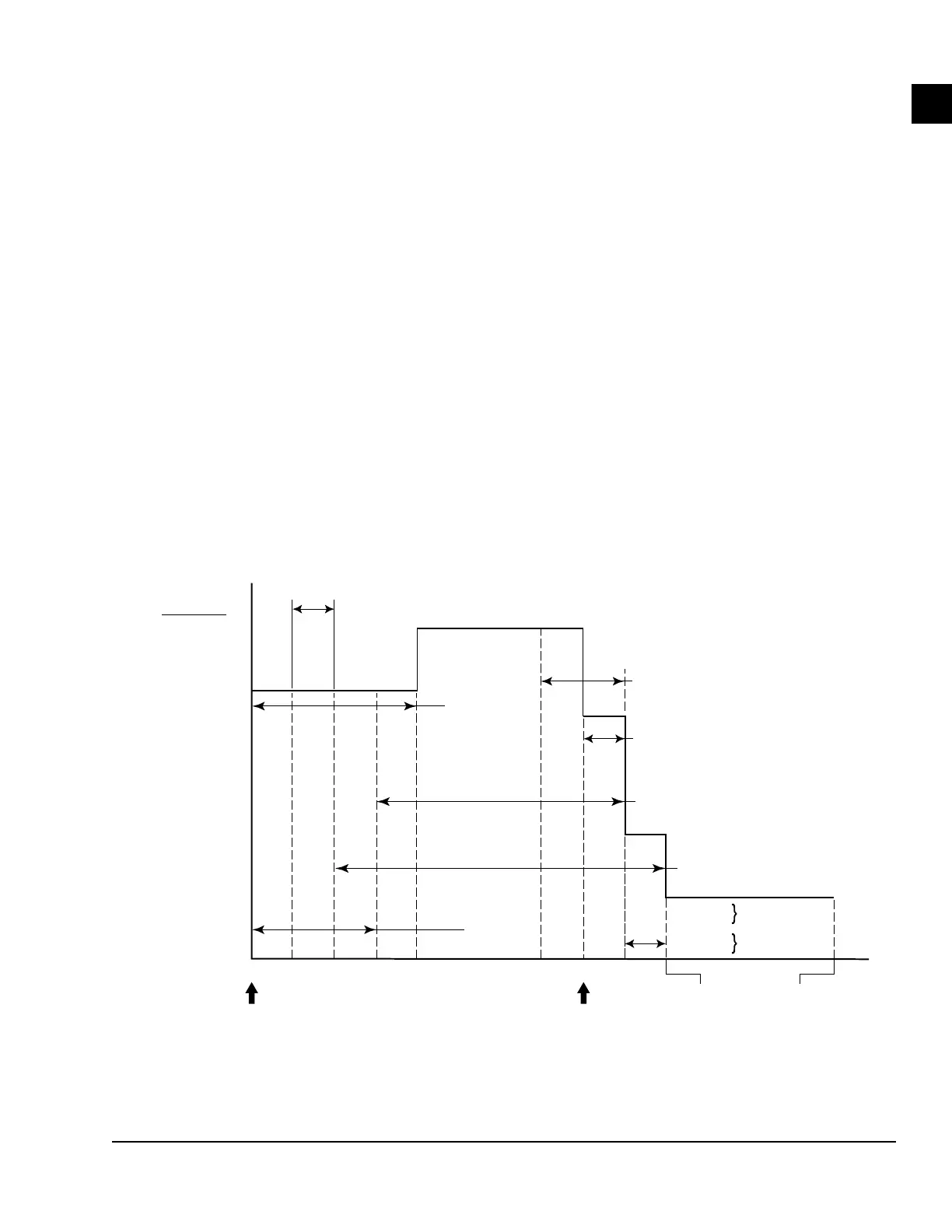

A timing diagram of the compressors’ start sequence

and shutdown is shown in Figure 3 on Page 9.

FIGURE 3 - YKEP CHILLER OPERATION SEQUENCE TIMING DIAGRAM

LD16023

0 10 13 45 50 110

(0.17) (0.22) (0.75) (0.83) (1.83)

VANES

CLOSED

MAN. OIL

PUMP

DISABLED

AUTO ZEROING DIFFERENTIAL

OIL PRESSURE TRANSDUCERS

** VANES CLOSING - TIME

DEPENDENT ON INITIAL

VANE POSITION

OIL PRESSURE CHECK

OIL PUMP ON

"SYSTEM

COASTDOWN"

"SYSTEM

SHUTDOWN"

TIME IN SECONDS (MINUTES)

DISPLAY

MESSAGE

"SYSTEM RUN"

"SYSTEM PRELUBE"

** "VANES CLOSING

BEFORE

SHUTDOWN"

ENERGIZE (OPEN)

LIQUID GEAR COOLING

SOLENOID (PRIMARY COMPRESSOR)

RESTART AFTER

ANTI-RECYCLE

(FOR EM STARTERS, 30 MIN)

(FOR VSD STARTERS, 5 STARTS THEN 10 MIN)

240 SEC

(4 MIN)

K7

Q3

150 SEC

(2.5 MIN)

FLOW

SWITCH

BYPASS

START STOP

Loading...

Loading...