106

The measuring position is shown as the

figure,

5. Assembling of the crankshaft connecting rod mechanism

5.1. Assembly of the piston and connecting rod

5.1.1. Use special tools to assemble the

piston, connecting rod and piston

pin in the following specified

procedures.

5.1.1.1. Smear lubricating oil to the

connecting rod pin hole, and make

the assembly according to the

marks for the same unit and in the

indicated direction.

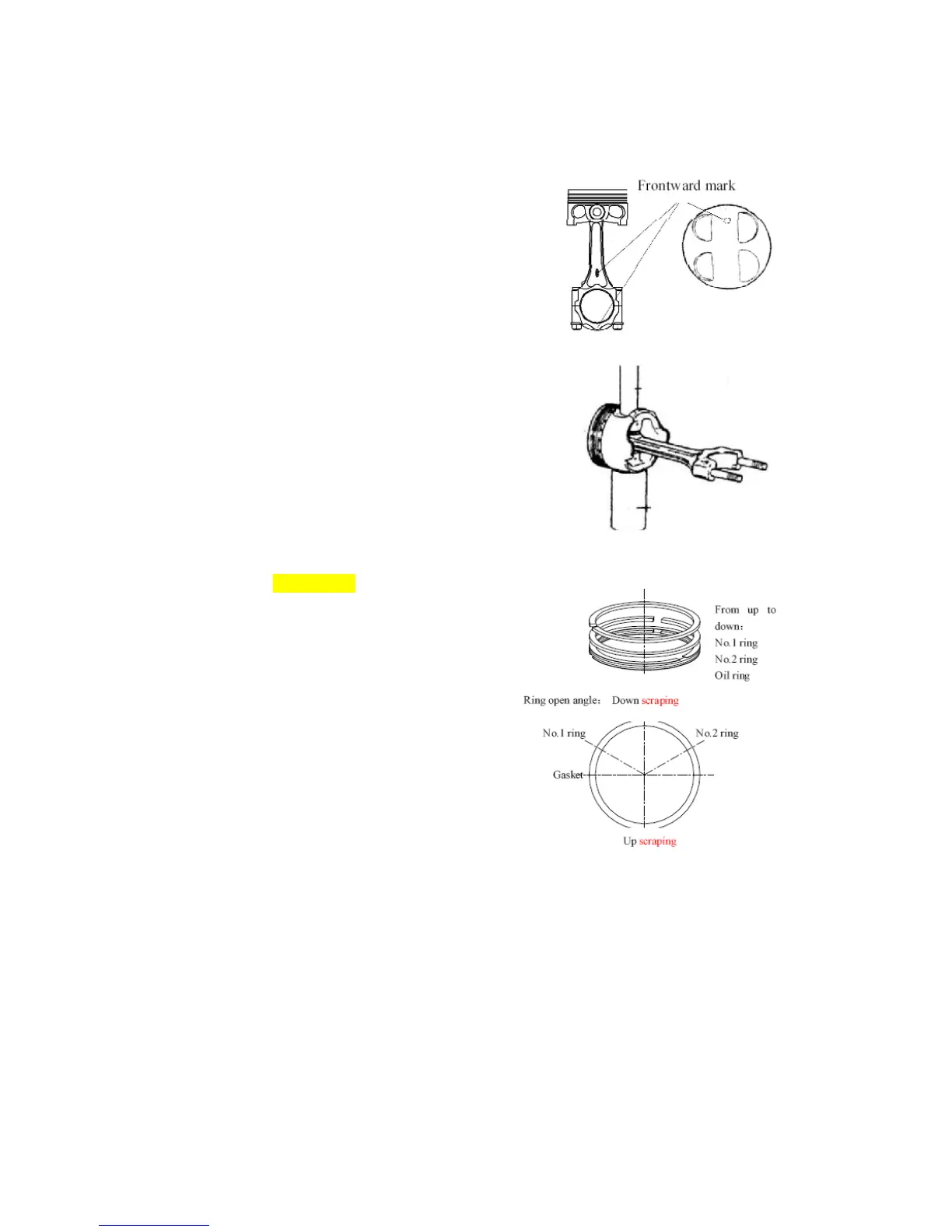

5.1.1.2. Make the installation shown as the

right figure.

5.1.1.3. Make adjustments and installation

of the piston and the connecting

rod shown as the right figure. After

smearing lubricating oil to the

piston pin, use pressurizing device

to assemble the piston and the

connecting rod.

Attention

· Pay attention to the assembling direction

when pressing in the piston pin;

The small bit of connecting rod should be

heated to 300℃/572℉ while pressing the

piston pin in the piston. Exert pressure in

the process of pressing to assure the

alignment of the pin.

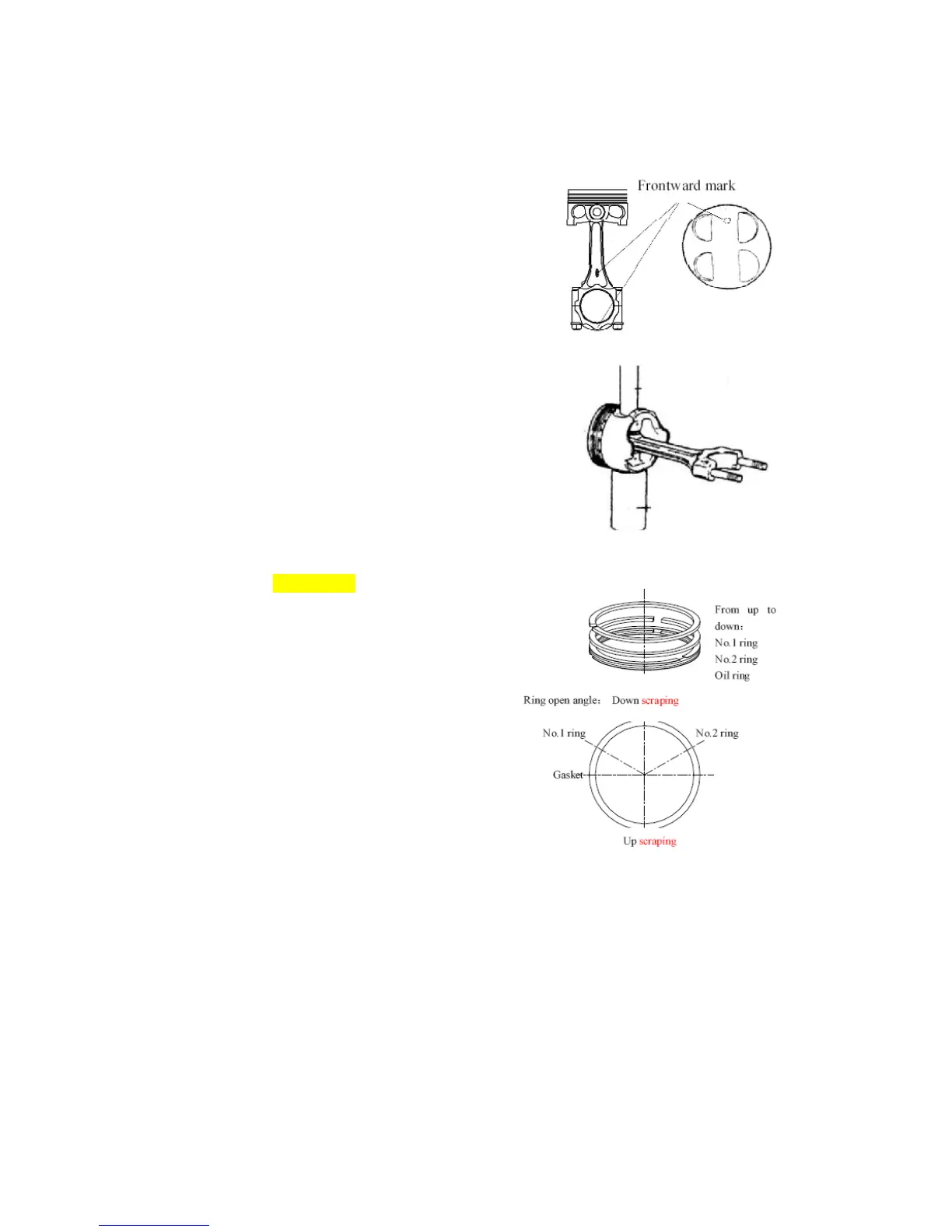

5.2. Install Primary ring, the secondary

ring and the oil ring in the following

specified procedures.

5.2.1. Install gas ring

Side face with marks should be upright,

install primary ring with piston ring tool.

5.2.2. Install oil ring (gasket ring, down

scraper and upper scraper) firstly,

then install the secondary ring, then

install the primary ring, Open

degree of every ring is shown as the

illustration:

Loading...

Loading...