– 65 –

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

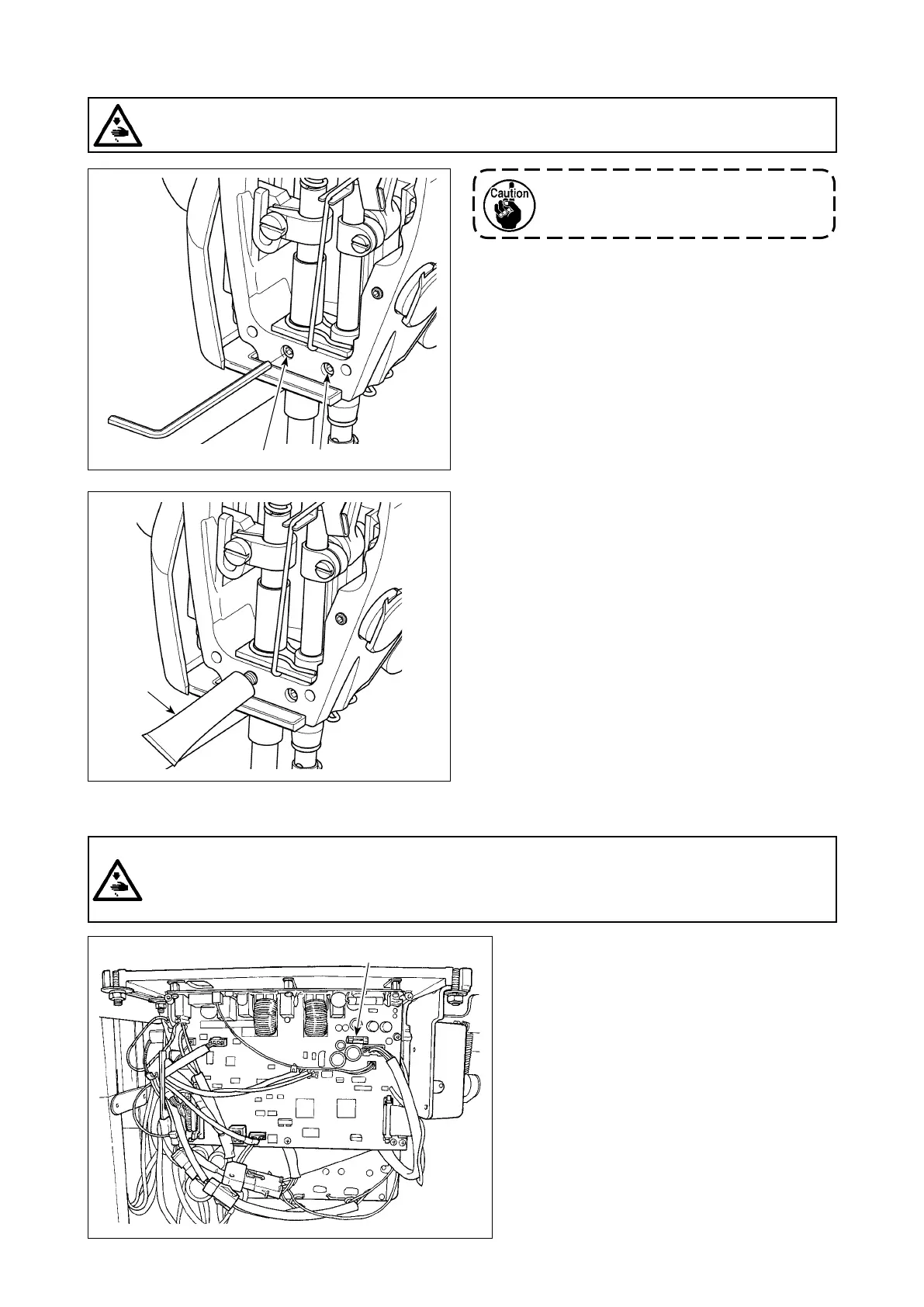

6-5. Applying grease to the needle bar lower bushing and the presser bar bushing

❶

❷

❸

Carry out greasing with the needle bar

installed.

1) Remove the face plate.

2) Remove presser bar bushing greasing screw ❷

and needle bar lower bushing greasing screw ❸

(only for the DDL-9000C-SMS) with a hexagonal

wrench.

3) Remove the cap of exclusive grease tube ❶.

Insert its tip into the oil hole and replenish grease

from exclusive grease tube ❶.

At this time, add grease until it overows the oil

hole.

4) Push overowing exclusive grease with the oil

lling screw into the oil hole.

5) Wipe the excess of grease off the area around the

oil hole.

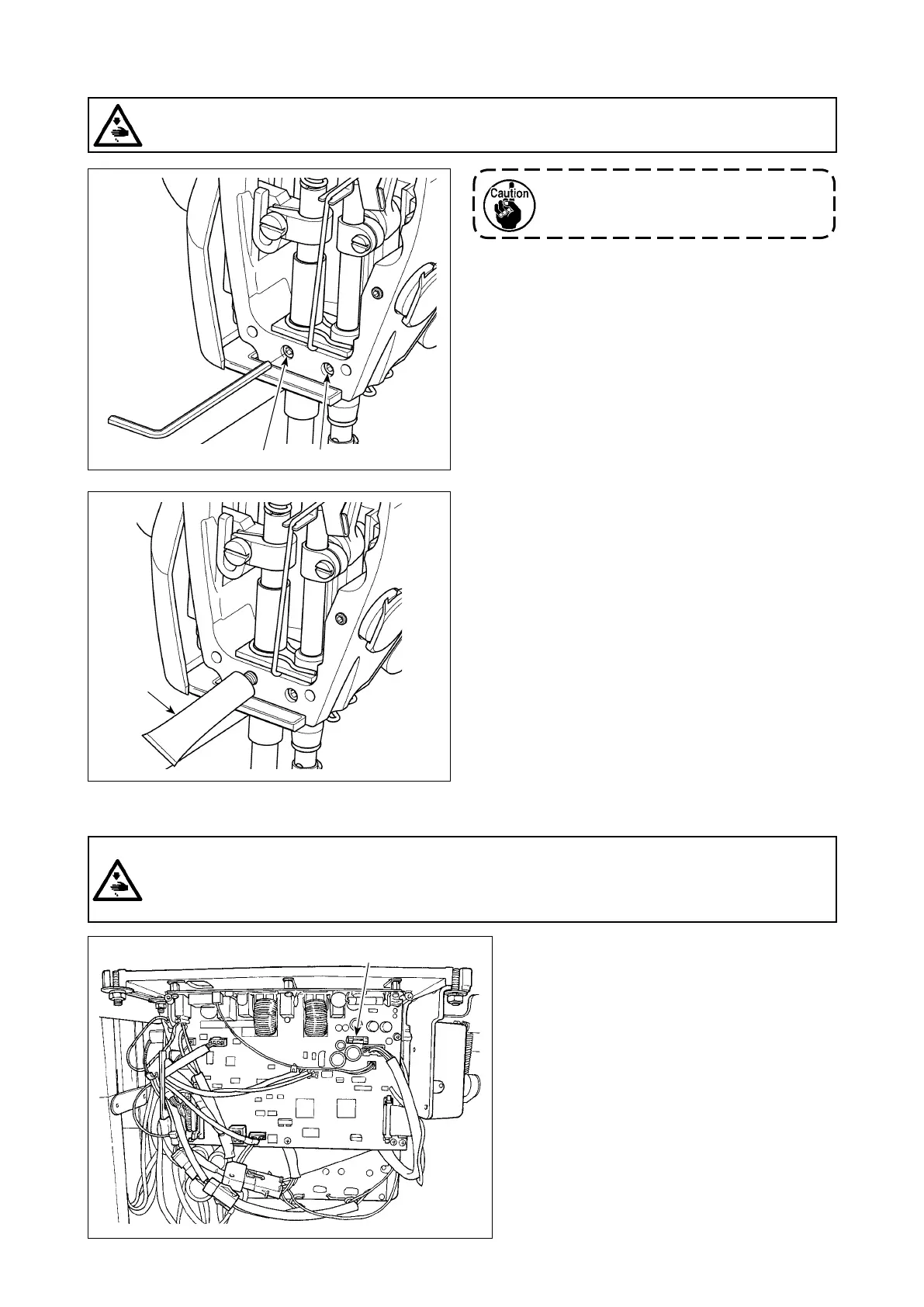

The machine uses the following one fuse :

MAIN PWB

❶ For 85V power supply protection

5A (time-lag fuse)

❶

DANGER :

1. To avoid electrical shock hazards, turn OFF the power and open the control box cover after about

ve minutes have passed.

2. Open the control box cover after turning OFF the power without fail. Then, replace with a new fuse

with the specied capacity.

6-6. Replacing the fuse

Loading...

Loading...