– 27 –

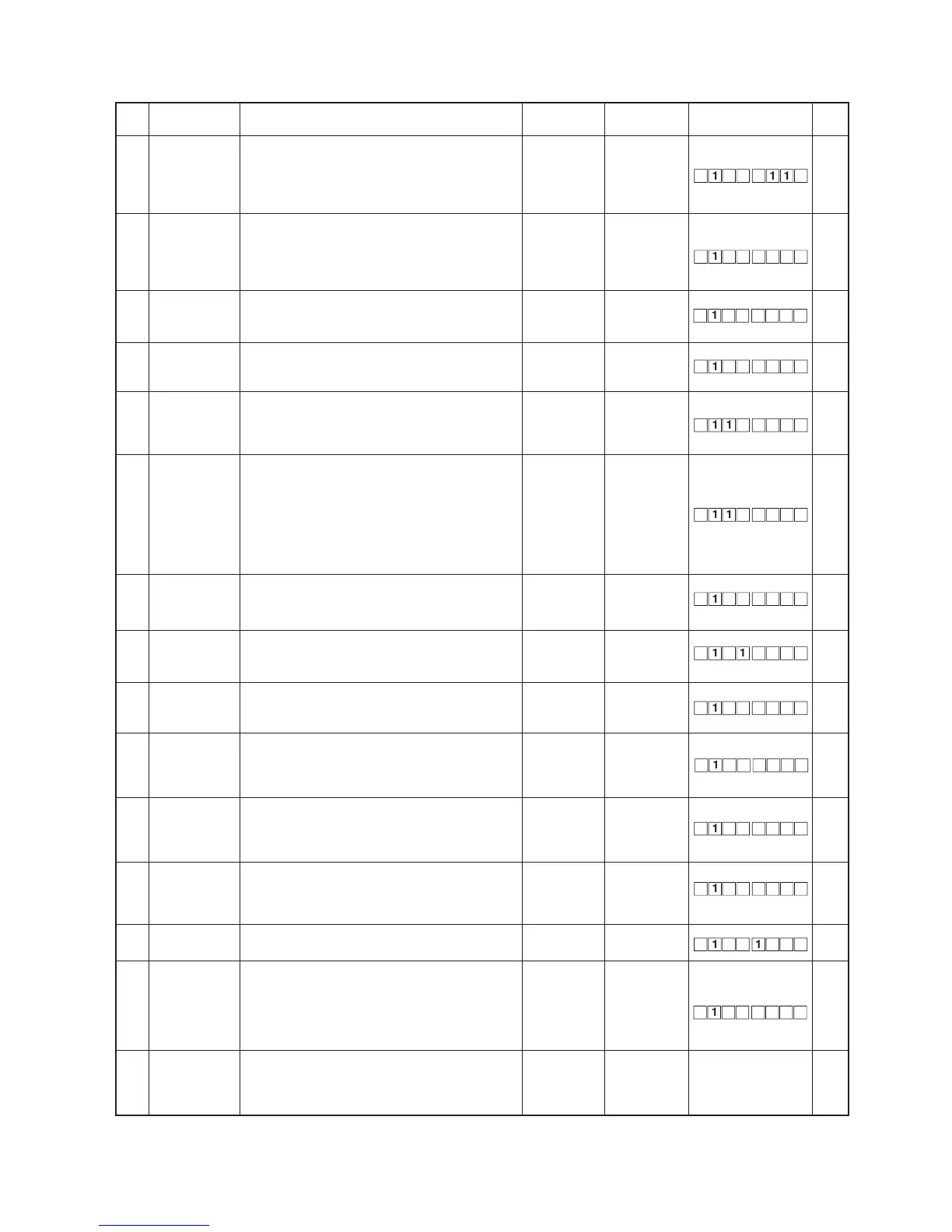

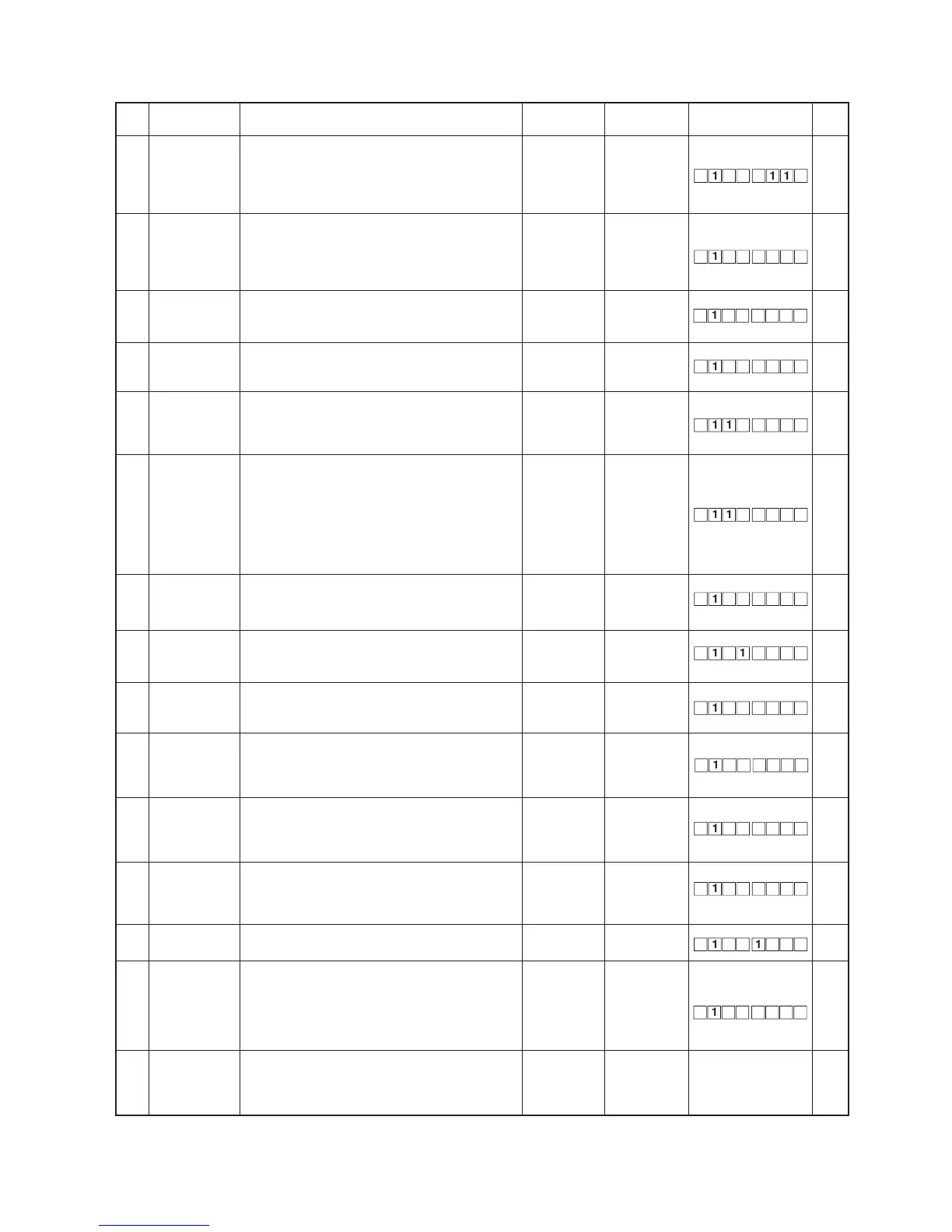

105 Back tack Back tack solenoid does not work during the movement 0 to 359 S

solenoid prohibition end point of view (No. 105) from a (°)

movement movement prohibition start angle (No. 106).

prohibition end

angle

106 Back tack Back tack solenoid does not work during the 0 to 359 S

solenoid movement prohibition end point of view (No. 105) (°)

movement from a movement prohibition start angle (No. 106).

prohibition

start angle

107 Reversing Stop brake start angle is set for reverse revolution 0 to 359 S 40

brake start to lift the needle. (°)

angle (0 : Up position end angle)

108 Reverse feed The output delay time at one shot of reverse feed 0 to 500 S

stitching one- stitching is specified. (10ms)

shot delay

110 Brake angle The brake start angle with the lowering needle 0 to 359 S

with lowering stopped at a given position is specified. (°)

needle stopped (0: Angle at end of up position detection)

* Activated when the setting value of No. 93 is 2 to 3

118 Grease up error In the case of grease-up error (E220, E221), this 0/1 S

reset error is cleared by setting the setup description at 1.

0 : Normal condition

1 : Grease-up error reset when the power is turned

on for the next time (After grease-up error has

been reset, this function is also canceled.)

* Prior to resetting the grease-up error, grease-up

treatment is always needed.

120 Main shaft Main shaft reference angle is compensated. -60 to 60 U 40

reference angle (°)

compensation

121 UP position Angle to detector UP position stating is compensa- -15 to 15 U 40

starting angle ted. (°)

compensation

122 DOWN position Angle to detect DOWN position stating is compen- -15 to 15 U 40

starting angle sated. (°)

compensation

123 Voltage change Improve start torque at the time of the low voltage. 0/1 S

torque (Only DDL-9000B Series)

improvement 0 : Normal movement

function 1 : Improve start torque

124 Setting of Setting to reduce the power consumption while the 0/1 U 40

energy-saving sewing machine is in standby state

function during 0 : Energy-saving mode is ineffective

standby 1 : Energy-saving mode is effective

125 Speed limit at Set a speed limit when back-tack solenoid works. 150 to MAX S

the time of the (MAX values are different by the head) (sti/min)

back-tack

solenoid

126 Motor lock Set time before detecting what the head locks. 500 to 2,000 S

detection time (ms)

127 Number of Set the number of stitches of the needles to sew 0 to 20 S

stitches of the with backstitch number of revolutions (No. 8) after (0.5 stitches)

low speed beginning backstitch was finished.

needles after

the beginning

backstitch

132 Movement Movement setting of back-tack solenoid S

to setting of

137 back-tack

solenoid

Loading...

Loading...