– 74 –

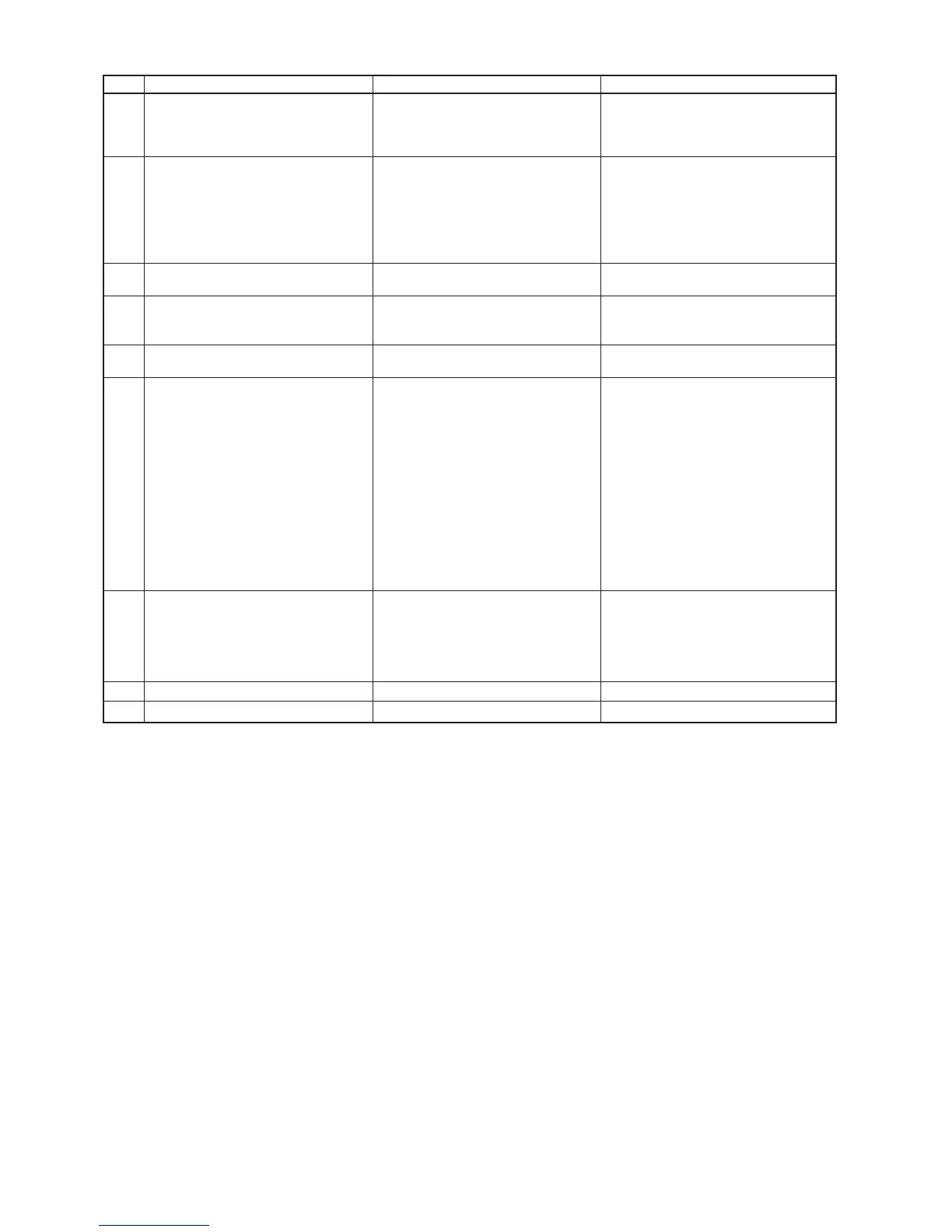

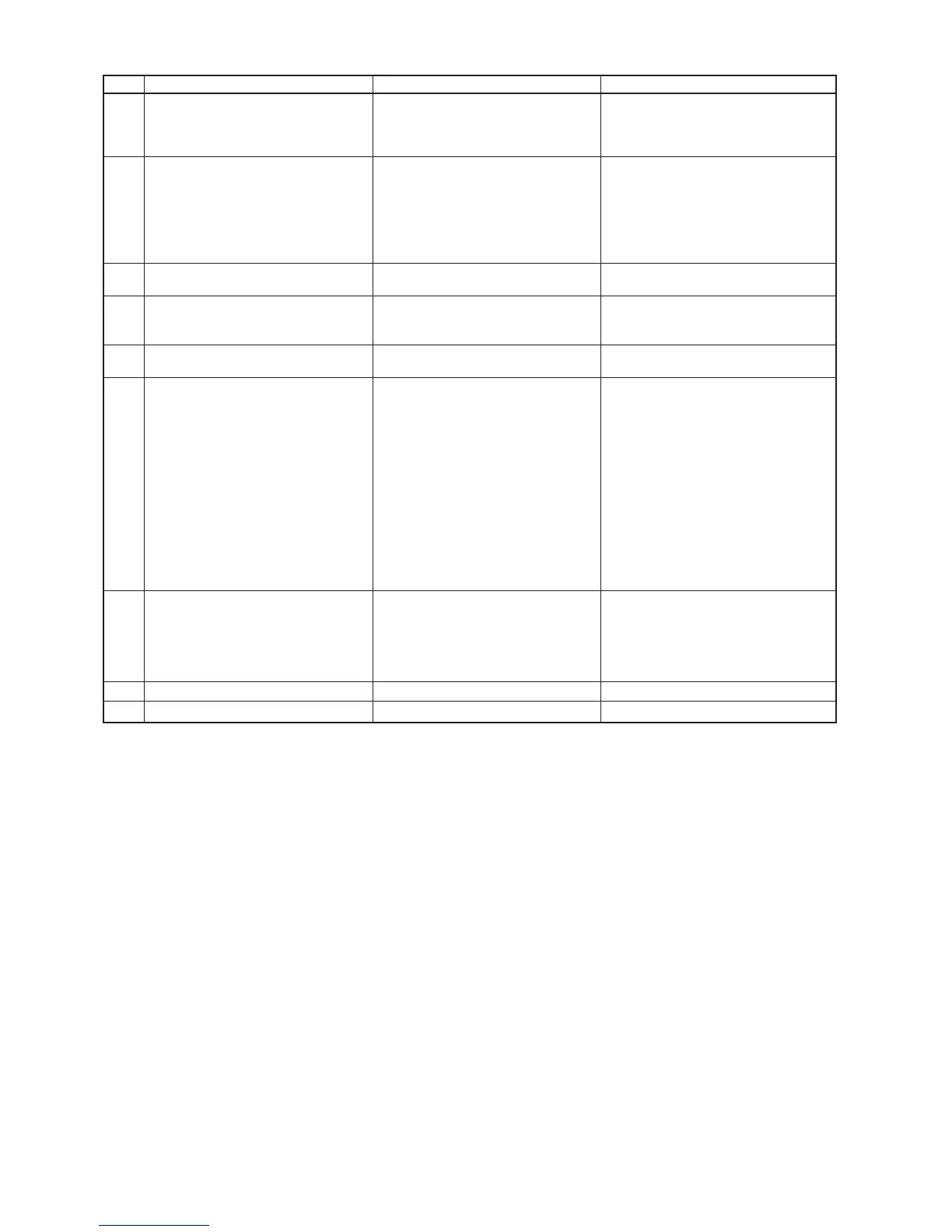

No. Description of error detected Cause of occurrence expected Items to be checked

E733 Inverse rotation of motor • This error occurs when the motor is • Connection of the encoder of main shaft

running at 500 sti/min or more in the motor is wrong.

opposite direction of that of rotation • Connection for the electric power of main

indication during motor is running. shaft motor is wrong.

E799 Predetermined time for thread trimming • Thread trimming sequence control is • Check whether the machine head actually

sequence is exceeded not completed within the predetermined installed is different from the machine head

time (three seconds). selection.

• Check whether the actual motor pulley

diameter is different from the motor pulley

setting (effective diameter).

• Check whether the belt has slackened.

E808 Solenoid short circuit • Solenoid power does not become • Check whether the machine head cord

normal voltage. is caught in the pulley cover or the like.

E809 Holding motion failure • Solenoid is not changed over to • Check whether the solenoid is abnormally

holding motion. heated. (CTL circuit board asm. Circuit

is broken)

E810 Solenoid short-circuit •

When the short-circuited solenoid is desired

• Check whether the solenoid is short-

to be driven. circuited.

E811 Abnormal voltage • When voltage higher than guaranteed • Check whether the applied power voltage

one is inputted. is higher than the rated voltage + (plus) 10%

• 200V has been inputted to SC-922 of or more.

100V specifications. • Check whether 100V/200V changeover

• JA : 220V is applied to 120V box. connector is improperly set.

• CE : 400V is applied to 230V box. In the aforementioned cases, POWER

p.c.b is broken.

• When voltage lower than guaranteed • Check whether the voltage is lower than

one is inputted. the rated voltage - (minus) 10% or less.

• 100V has been inputted to SC-922 of • Check whether 100V/200V changeover

200V specifications. connector is improperly set.

• JA : 120V is applied to 220V box.

•Inner circuit is broken by the applied • Check whether fuse or regenerative

overvoltage. resistance is broken.

E906 Operation panel transmission failure • Disconnection of operation panel cord. • Check the operation panel connector

• Operation panel has broken. (CN38) for loose connection and

disconnection.

•Check whether the operation panel cord

has broken since the cord is caught in

the machine head.

E924 Motor driver failure • Motor driver has broken.

E942 Faulty EEPROM • Data cannot be written on the EEPROM. •Turn the power OFF.

Loading...

Loading...