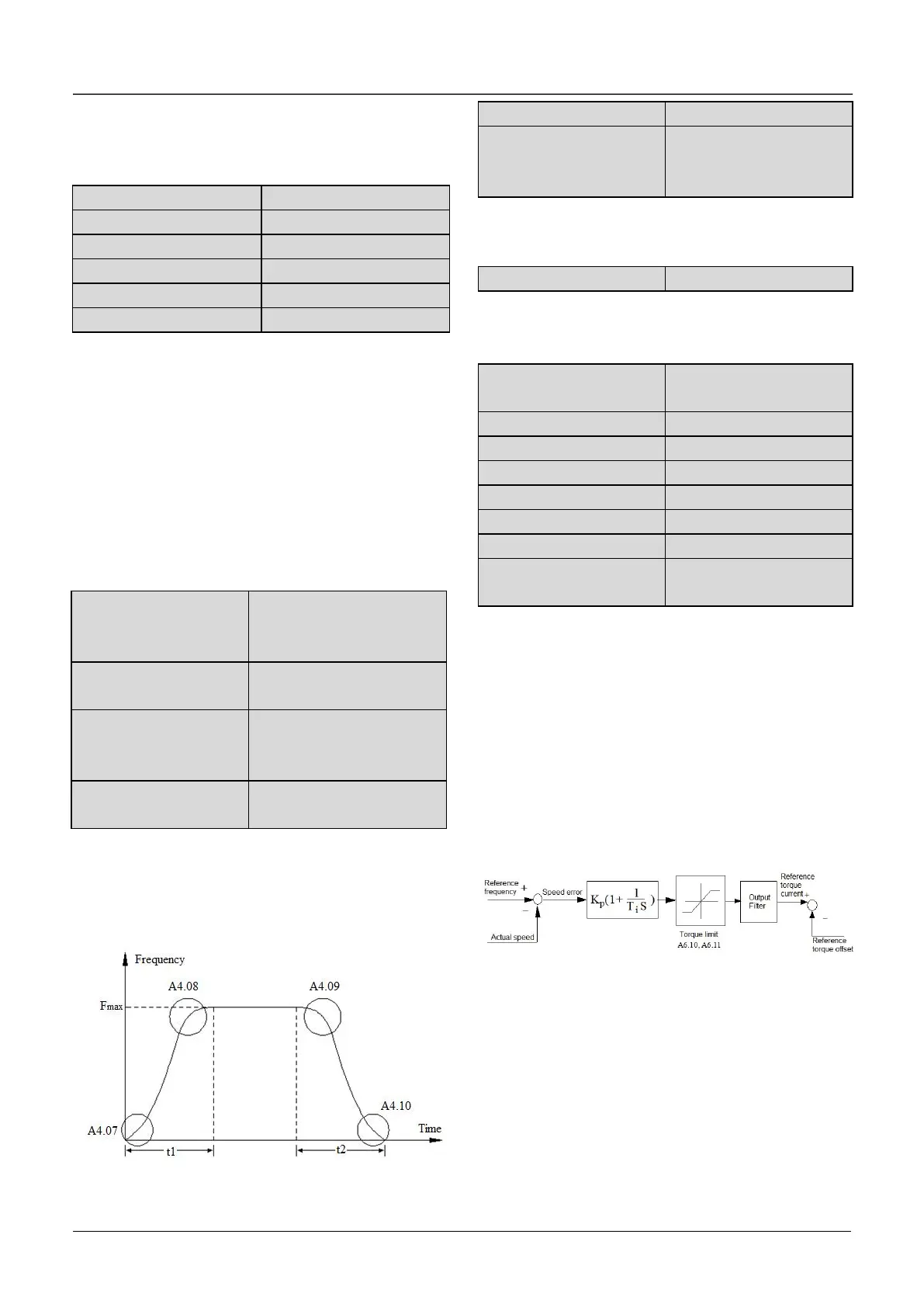

S curve Acc/Dec mode can smooth acceleration

and deceleration, suitable for application like lift,

conveyer belt.

Acc time is the time taken for the motor to

accelerate from 0Hz to the maximum frequency (as

set in A0.08), see t

2

in Fig.6-12. Dec time is the time

taken for the motor to decelerate from maximum

frequency (A0.08) to 0Hz, see t

2

in Fig.6-12.

CV100 define three kinds of Acc/Dec time, and the

drive’s Acc/Dec time 1~4 can be selected by

different combinations of control terminals, refer to

the introductions of A6.00~A6.04 for the definitions

of terminals used to select Acc/Dec time.

A4.07 S curve

acceleration starting

time

10.0%~50.0% (Acc time)

A4.07+ A4.08≤90【20.0%】

A4.08 S curve

acceleration ending time

10.0%~70.0% (Acc time)

A4.07+ A4.08≤90【20.0%】

A4.09 S curve

deceleration starting

time

10.0%~50.0% (Dec time)

A4.09+ A4.10≤90【20.0%】

A4.10 S curve

deceleration ending time

10.0%~70.0% (Dec time)

A4.09+ A4.10≤90【20.0%】

A4.07~A4.10 is only valid when A4.00 is set as 1 (S

curve Acc/Dec mode),and it must make sure

A4.07+A4.08≤90%, A4.09+ A4.10≤90%,as shown

in Fig.6-14.

Fig.6-14 Acc/Dec starting time and ending time

A4.22 Switch frequency

for Acc/Dec time 1 and

Acc/Dec time 2.

It will use Acc/Dec time 2 when output frequency is

lower than A4.22.

A5.00 Speed/Torque

control mode

0:Speed control mode

1:Torque control mode

A5.07 ASR1/2 switching

frequency

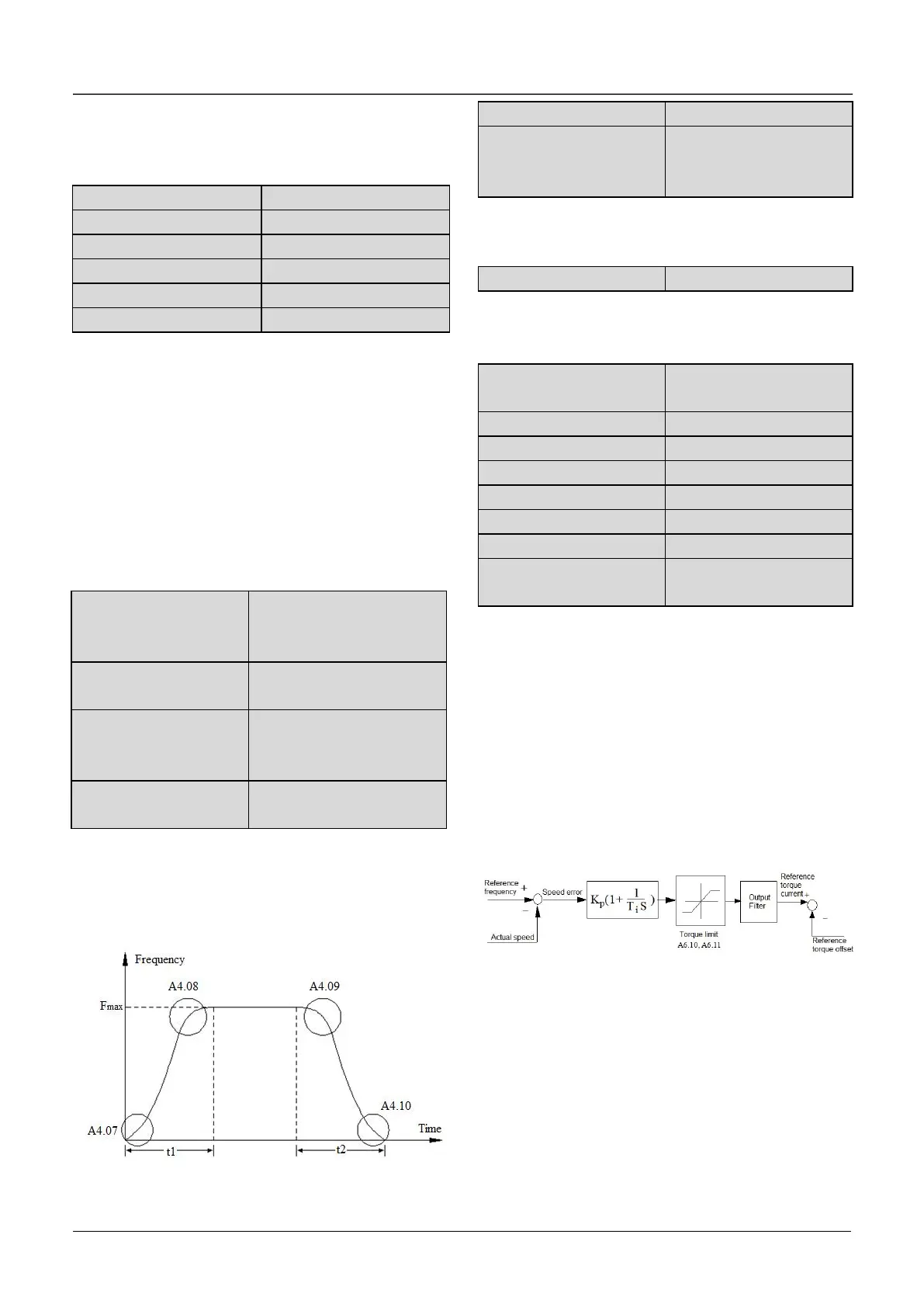

The parameters A5.00 ~ A5.07 are only valid for

vector control mode.

Under vector control mode,it can change the speed

response character of vector control through

adjusting the proportional gain P and integral time I

for speed regulator.

1.The structure of speed regulator (ASR) is shown

in Fig.6-13.In the figure, K

P

is proportional gain P. T

I

is integral time I.

Fig.6-13 Speed regulator

When integral time is set to 0 (A5.02=0,A5.05=0),

then the integral is invalid and the speed loop is just

aproportional regulator.

2. Tuning of proportional gain P and integral time I

for speed regulator(ASR).

Loading...

Loading...