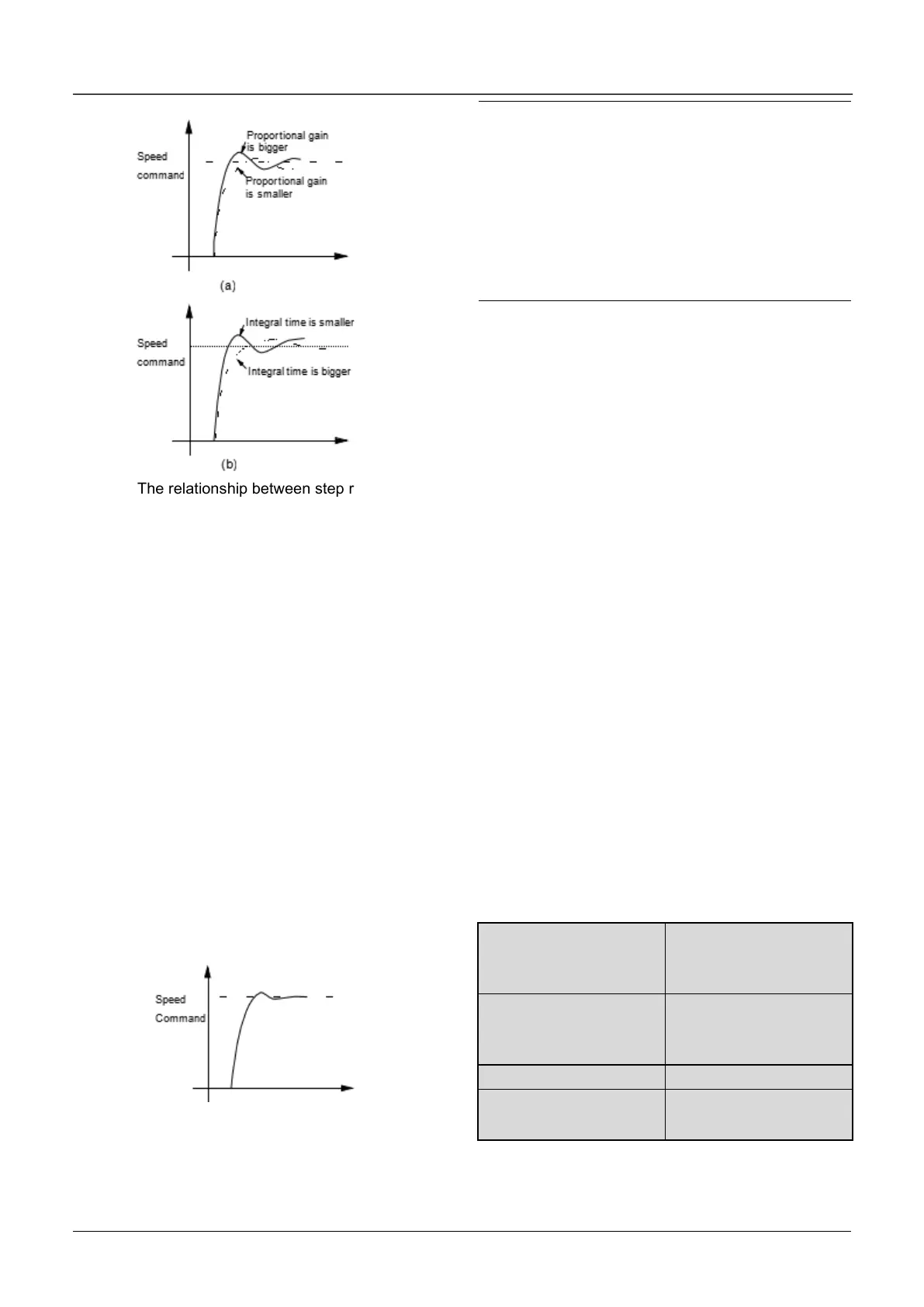

Fig.6-14 The relationship between step response and

PI parameters of speed regulator(ASR)

When increasing proportional gain P, it can speed

up the system’s dynamic response. But if P is too

big, the system will become oscillating.

When decreasing integral time I, it can speed up the

system’s dynamic response. But if I is too small, the

system will become overshoot and easily

oscillating.

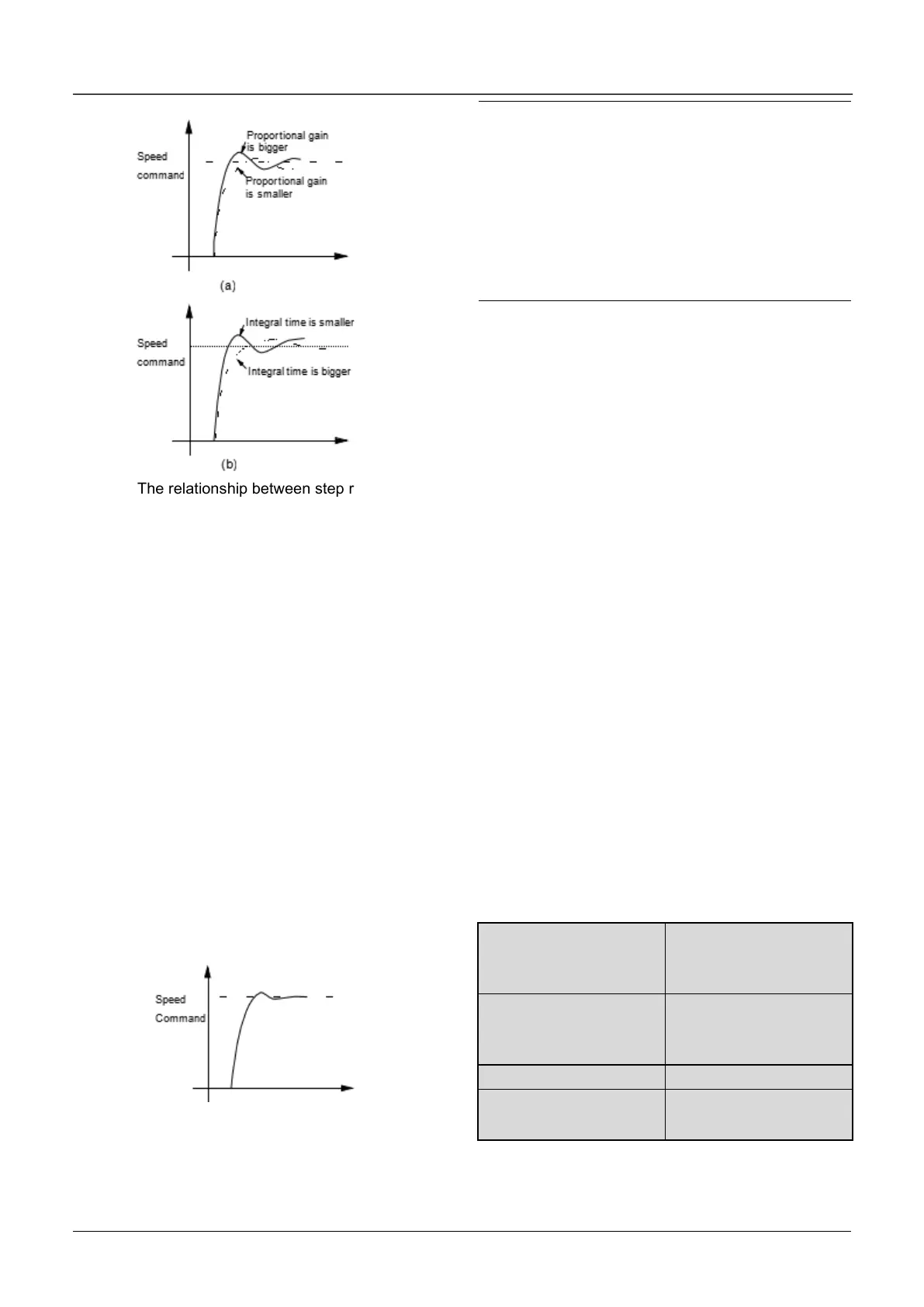

Generally, to adjust proportional gain P firstly. The

value of P can be increased as big as possible if the

system don’t become oscillating. Then adjust

integral time to make the system with fast response

but small overshoot. The speed step response

curve of speed, when set a better value to P and I

parameters, is shown in Fig.6-15. (The speed

response curve can be observed by analog output

terminal AO1 and AO2,please refer to Group A6)

Fig.6-15 The step response with better dynamic

performance

Note:

If the PI parameters are set incorrectly, it will cause

over-voltage fault when the system is accelerated to

high speed quickly(If the system doesn’t connect

external braking resistor or braking unit),that is

because the energy return under the system’s

regenerative braking when the system is dropping

after speed overshoot. It can be avoided by

adjusting PI parameters

3. The PI parameters’ adjustment for speed

regulator (ASR) in the high/low speed running

occasion

To set the switching frequency of ASR (A5.07) if the

system requires fast response in high and low

speed running with load. Generally when the

system is running at a low frequency, user can

increase proportional gain P and decrease integral

time I if user wants to enhance the dynamic

response. The sequence for adjusting the

parameters of speed regulator is as following:

1)Select a suitable switching frequency( A5.07).

2)Adjust the proportional gain (A5.01) and integral

time(A5.02) when running at high speed,ensure the

system doesn’t become oscillating and the dynamic

response is good.

3)Adjust the proportional gain (A5.04) and integral

time(A5.05) when running at low speed, ensure the

system doesn’t become oscillating and the dynamic

response is good.

4. Get the reference torque current through a delay

filter for the output of speed regulator.A5.03 and

A5.06 are the time constant of output filter for ASR1

and ASR2.

Loading...

Loading...