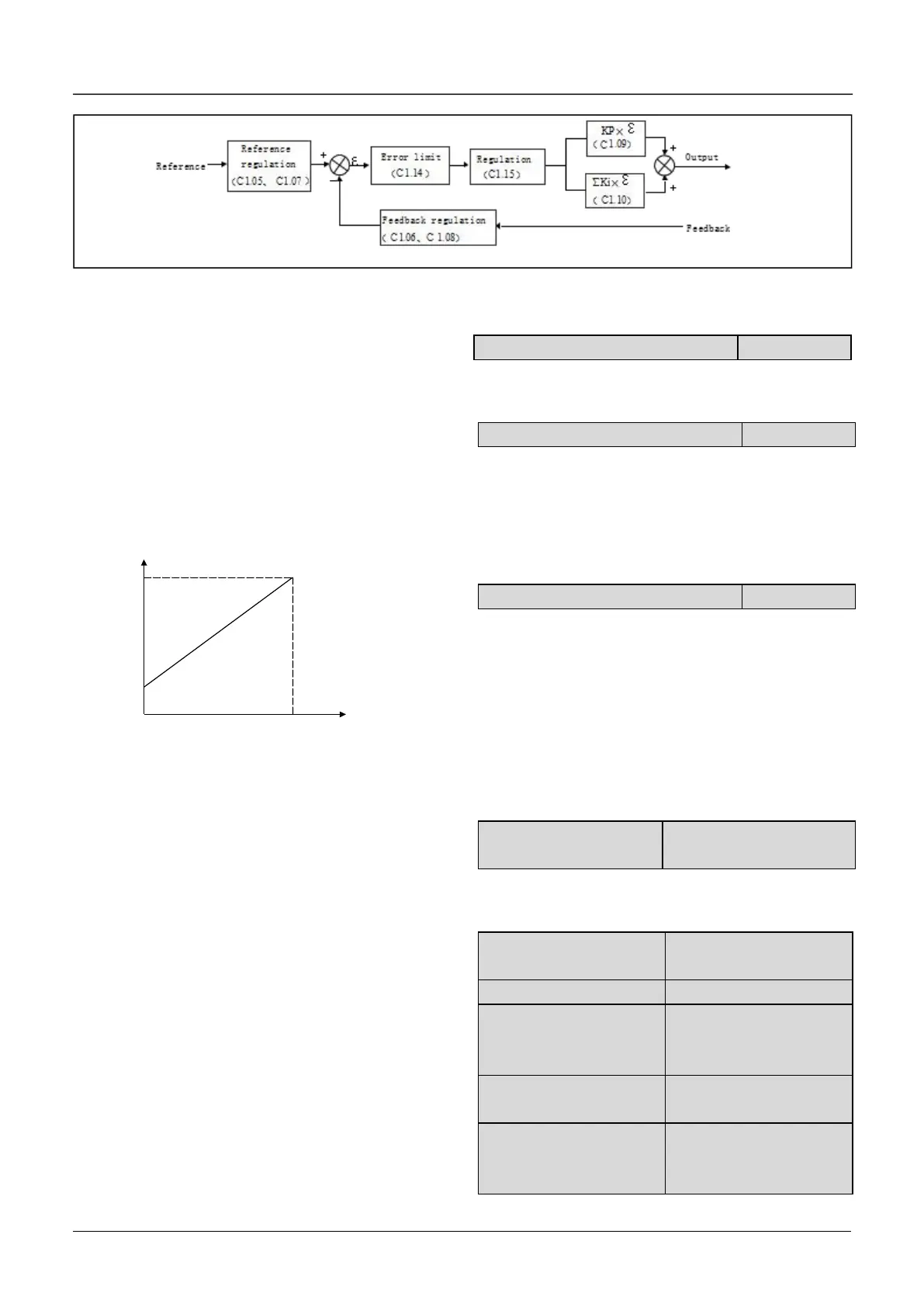

Fig.6-41 Principle diagram of process close-loop control

There are two features of internal close-loop of

FV20:

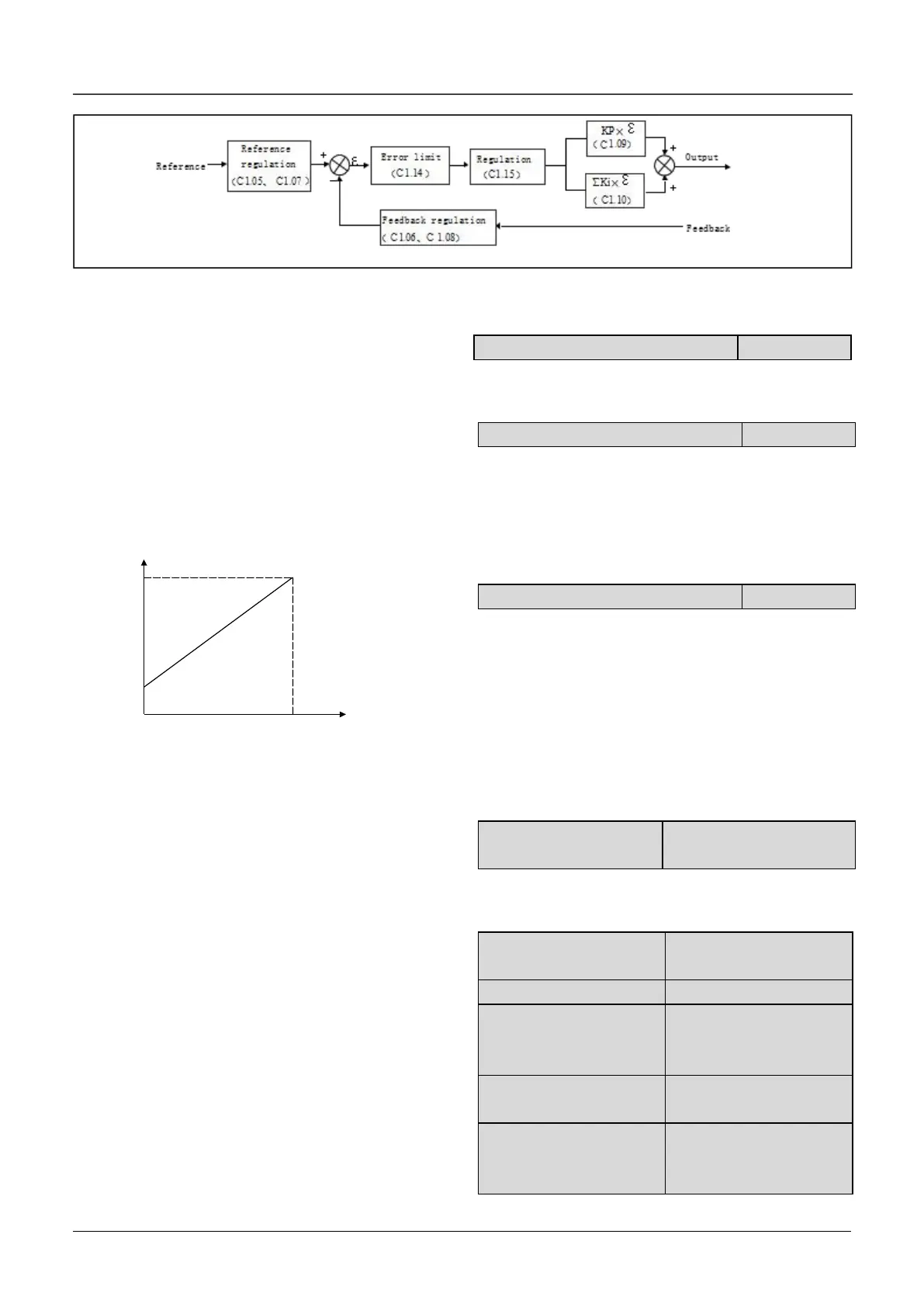

The relationship between reference and feedback

can be defined by C1.05~C1.08

For example: In Fig.6-40, if the reference is analog

signal of -10~10V, the controlled value is 0~1MP,

and the signal of pressure sensor is 4~20mA, then

the relationship between reference and feedback is

shown in Fig. 6-42.

Fig.6-42 Reference and feedback

After the control type is determined, follow the

procedures below to set close loop parameters.

1) Determine the close-loop reference and

feedback channel (C1.01 and C1.02);

2) The relationship between close-loop reference

and feedback value (C1.05 ~ C1.08) should be

defined for analog close-loop control;

3) Determine the close-loop regulation

characteristic, if the relationship between motor

speed and the reference is opposite, then set the

close-loop regulation characteristic as negative

characteristic(C1.15=1).

4) Set up the integral regulation function and

close-loop frequency presetting function (C1.16 ~

C1.18);

5) Adjust the close-loop filtering time, sampling

cycle, error limit and gain(C1.09~C1.14).

C1.00 Close-loop control function

C1.01 Reference channel selection

0: digital input

Take the value of C1.03 .

1: AI1 analog input.

2: AI2 analog input

3:Keyboard potentiometer analog voltage input.

C1.02 Feedback channel selection

0: AI1 analog input

1: AI2 analog input

2: AI1+ AI2

3: AI1-AI2

4: Min{ AI1,AI2}

5: Max{ AI1,AI2}

6: Pulse DI

Settings of AI are the same as above.

C1.03 Digital setting of

reference

This function can realize digital setting of reference

via panel or serial port.

C1.04 Close-loop speed

reference

C1.06 Feedback value

corresponding to the Min

reference

C1.08 Feedback value

corresponding to the Max

reference

Loading...

Loading...