Section 9

Troubleshooting

20479300

2-2012/Rev 01

9-4

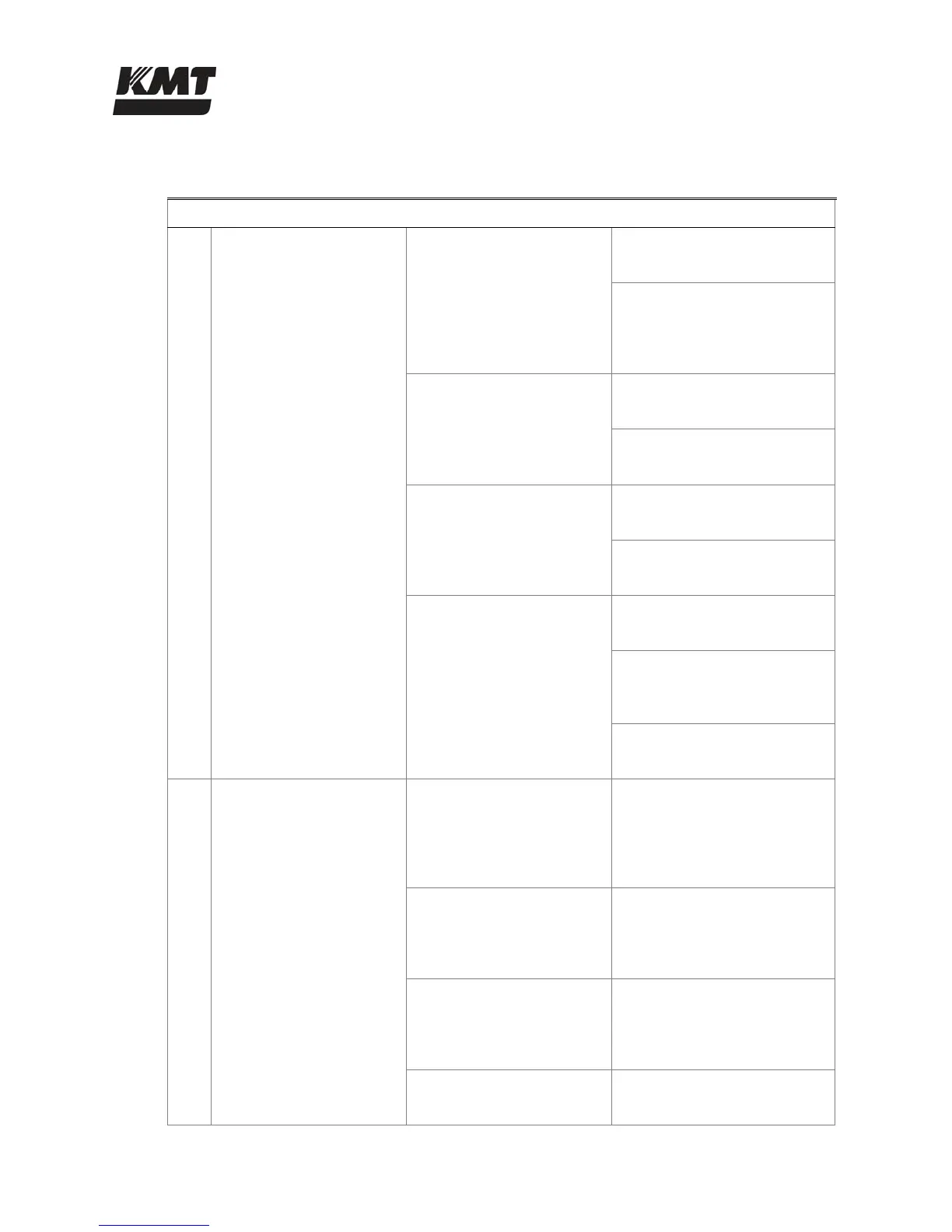

Table 9-1

S50 Troubleshooting Guide

Malfunction Indication Comments

9.

Abnormal fluctuations in

high pressure water signal

Large, worn or damaged

orifice

Make sure the orifice does not

exceed the capacity of the pump.

Make sure the orifice is in good

working condition. Verify that

the jewel is installed in the

orifice mount.

Check valve leakage Inspect the discharge check

valves in the sealing heads.

Inspect the inlet check valves in

the sealing heads.

Seal leakage Inspect the high pressure seal on

the plunger.

Inspect the sealing head-to-

cylinder sealing surfaces.

Hydraulic control

malfunction

Check the operation of the

hydraulic relief valve.

Verify that the directional

control valve is shifting

properly.

Check the operation of the

proximity switches.

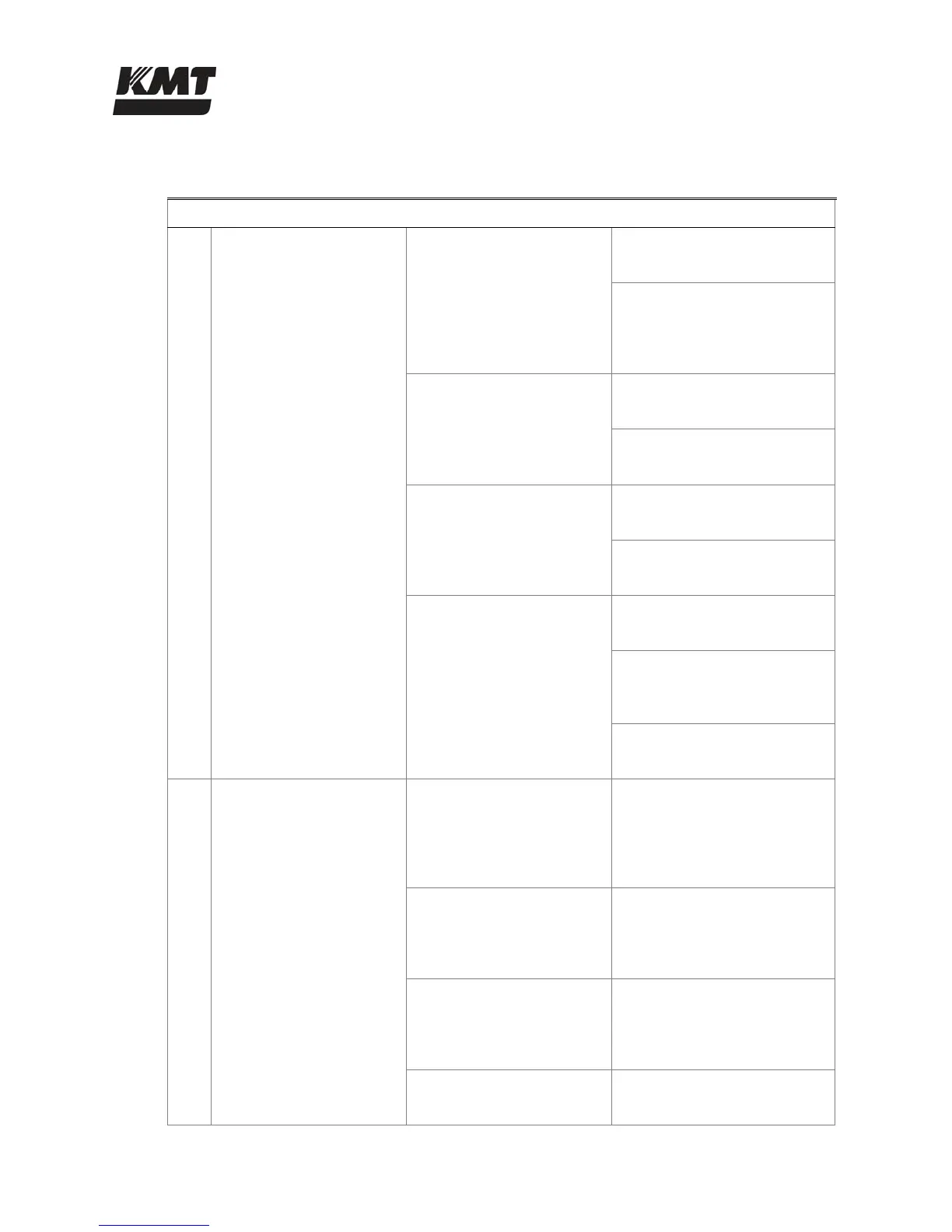

10.

Hot surfaces on the high

pressure cylinder

components

Leaking discharge check

valve

Inspect the condition of the seat,

poppet valve, spring, poppet pin

and sealing head surface on the

discharge end of the sealing

heads.

Leaking inlet check valve Inspect the condition of the

poppet valve and poppet retainer

on the inlet end of the sealing

heads.

Damaged sealing head Check the cone flange surface of

the sealing head for scratches or

mechanical damage and replace

if necessary.

Damaged high pressure

cylinder

Check the high pressure cylinder

for cracks.

Loading...

Loading...