Section 4

Low Pressure Water System

20479275

9-2010/Rev 02

4-3

Filter Assembly and Strainer Maintenance

The life of the filter element is directly related to the quality of the inlet water. The condition of

the filter element can be monitored by observing the Booster Pressure Gauge on the front of the

machine. Document the pressure reading when the filter element is new. The element should be

replaced when the pressure drops to 15 psi (1 bar) below the original value. When the filter

element is replaced, the strainer should also be cleaned.

The following procedure is used to replace the filter element and clean the strainer.

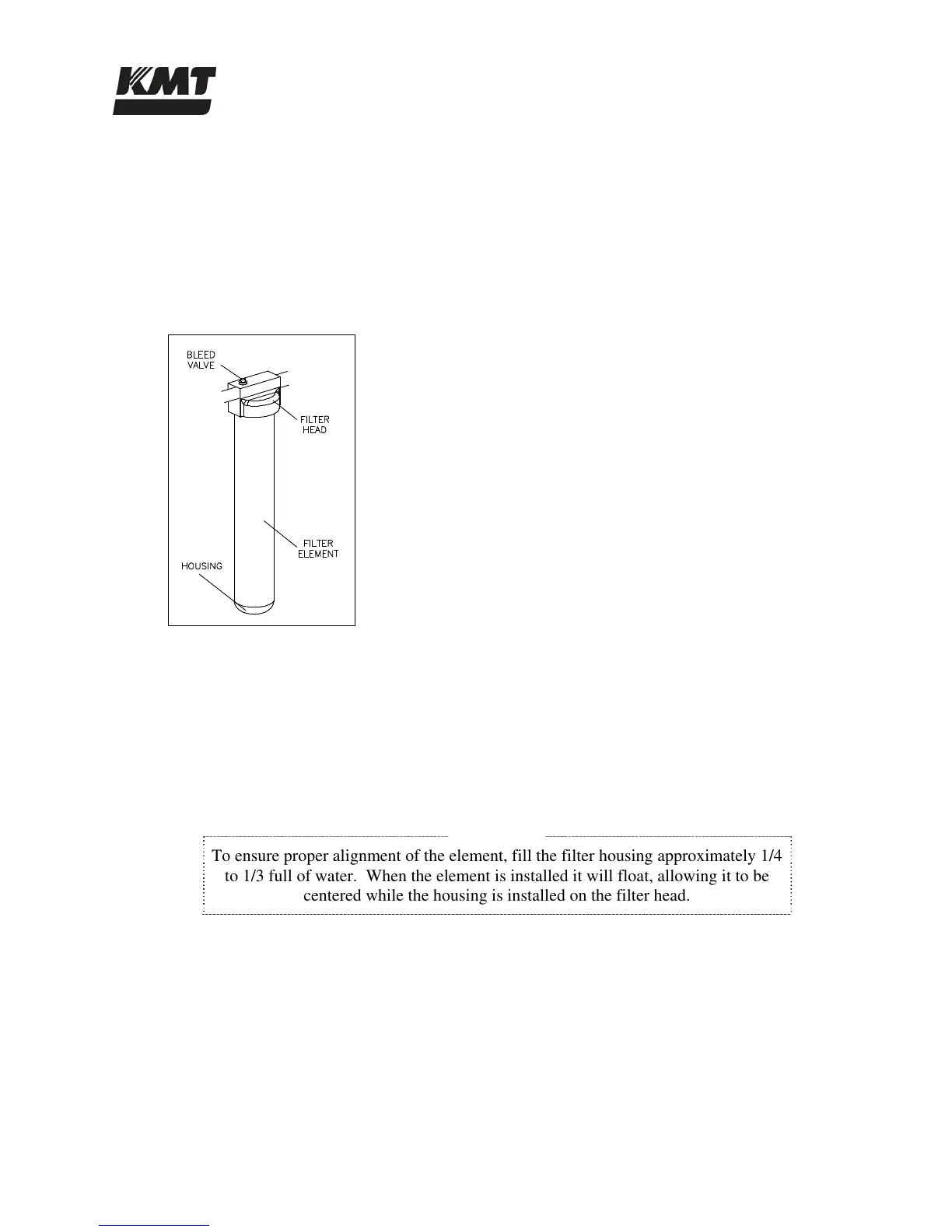

Figure 4-2: Filter Element

1. Turn the cutting water supply off.

2. Press the red bleed valve on the filter head to release any pressure trapped inside the

housing.

3. Use a filter wrench to unscrew the housing and remove the old element.

4. Install the new element. Apply FML-2 grease to the o-ring in the filter housing and use

the filter wrench to replace the housing.

NOTE

To ensure proper alignment of the element, fill the filter housing approximately 1/4

to 1/3 full of water. When the element is installed it will float, allowing it to be

centered while the housing is installed on the filter head.

Loading...

Loading...