Section 2

Installation

20479262

9-2010/Rev 02

2-5

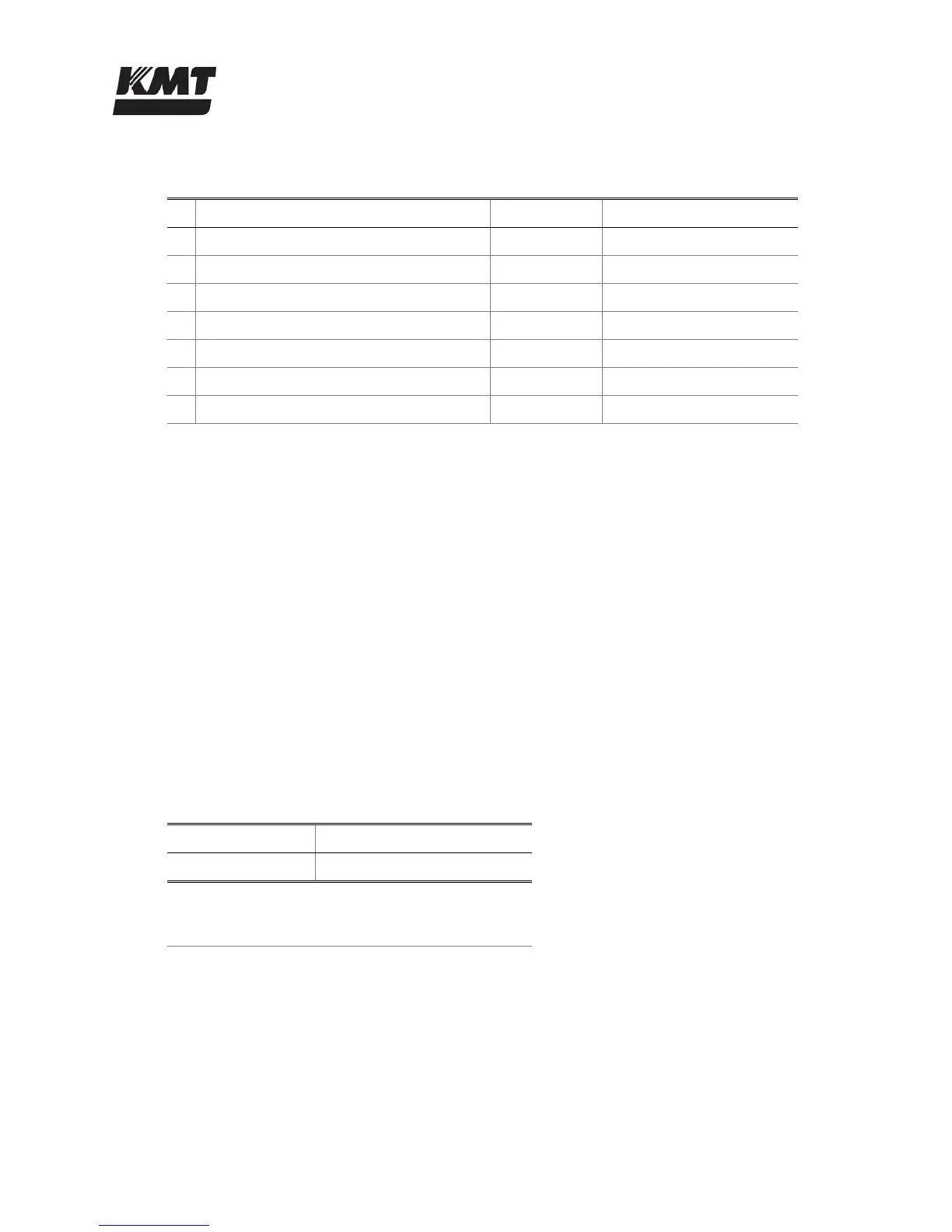

Table 2-3

Service Connections

Connection Height

A Drain 1/2” NPT 12.21” (310 mm)

B Cutting Water In 1/2” NPT 16.26” (413 mm)

G Contaminated Waste 1/2” NPT 20.26” (515 mm)

C Cooling Water In (oil-to-water models) 1/2” NPT 23.76” (604 mm)

D Cooling Water Out (oil-to-water models) 1/2” NPT 27.76” (705 mm)

F Cutting Water Out 9/16” HP 32.76” (832 mm)

E Plant Air In 1/4” NPT 36.76” (934 mm)

Cooling Water (Oil-to-Water Models)

Inlet cooling water flows through the oil-to-water heat exchanger in the hydraulic system to

control heat buildup in the hydraulic oil. The cooling water is then discharged through the

cooling water out port to either the drain or routed to a customer supplied water chiller.

Cooling water supply piping must be sized to meet the flow and pressure requirements of the

equipment. If municipal or well water is used for cooling, ensure the supply flow and pressure

meet the requirements in Section 10, Specifications.

If a facility-wide chilled water system is used for cooling, ensure there is a minimum of 35 psi

(2.4 bar) pressure differential between the facility supply and discharge plumbing. Installation of

an in-line pressure boosting pump may be necessary to provide adequate cooling flow. Dedicated

chilled water systems should be sized according to pump horsepower as illustrated in Table 2-4,

Chilled Water Systems.

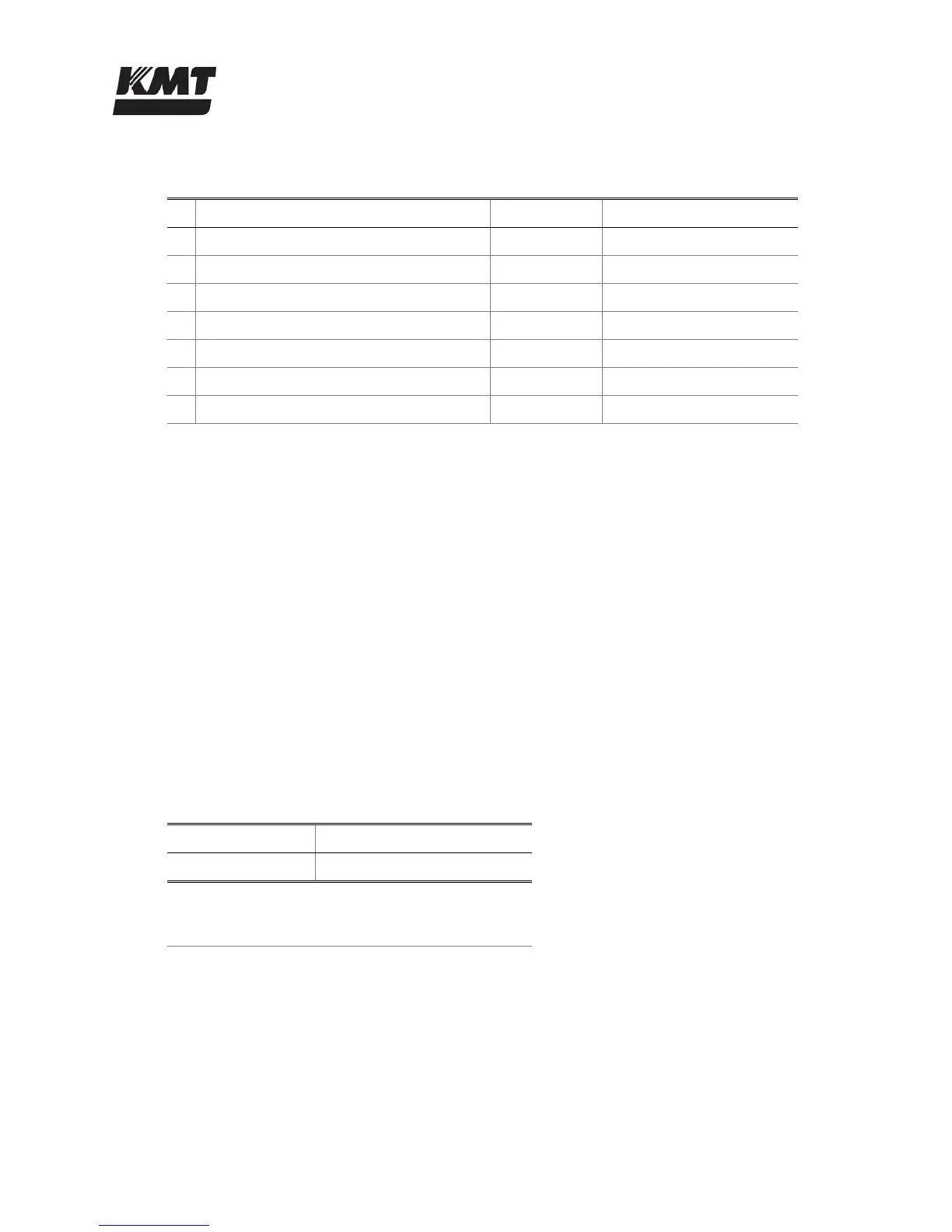

Table 2-4

Chilled Water Systems

Cooling Requirements at Full Capacity

Horsepower BTU/HR

50 22,000

Note: Coolant flow to the heat exchanger is regulated

by the temperature of the contents in the

hydraulic reservoir and will be shut off at times.

Cutting Water

Inlet cutting water is routed to the intensifier where it is pressurized and delivered to the cutting

head. The cutting water supply must meet the minimum water quality standards outlined in

Section 10, Specifications. Poor water quality will drastically shorten component life and void

the warranty.

Loading...

Loading...