20479279

9-2010/Rev 02

5-1

SECTION 5

RECIRCULATION SYSTEM

5.1 Overview

The oil recirculation circuit is a cooling and filtration system that provides properly conditioned

oil to the main hydraulic system. Hydraulic oil is maintained at the proper operating temperature

and condition by continuous recirculation.

5.2 Operation (Oil-to-Water Models)

Cooling water is introduced through the 1/2-inch NPT connection on the bulkhead of the

machine. A water modulating valve in the outlet line regulates the cooling flow through the heat

exchanger. The valve is factory set, but may require adjustment to maintain the operating oil

temperature at 115 F (46 C). Oil temperature can be visually monitored from a dual scale

level/temperature sight gauge on the side of the hydraulic oil reservoir.

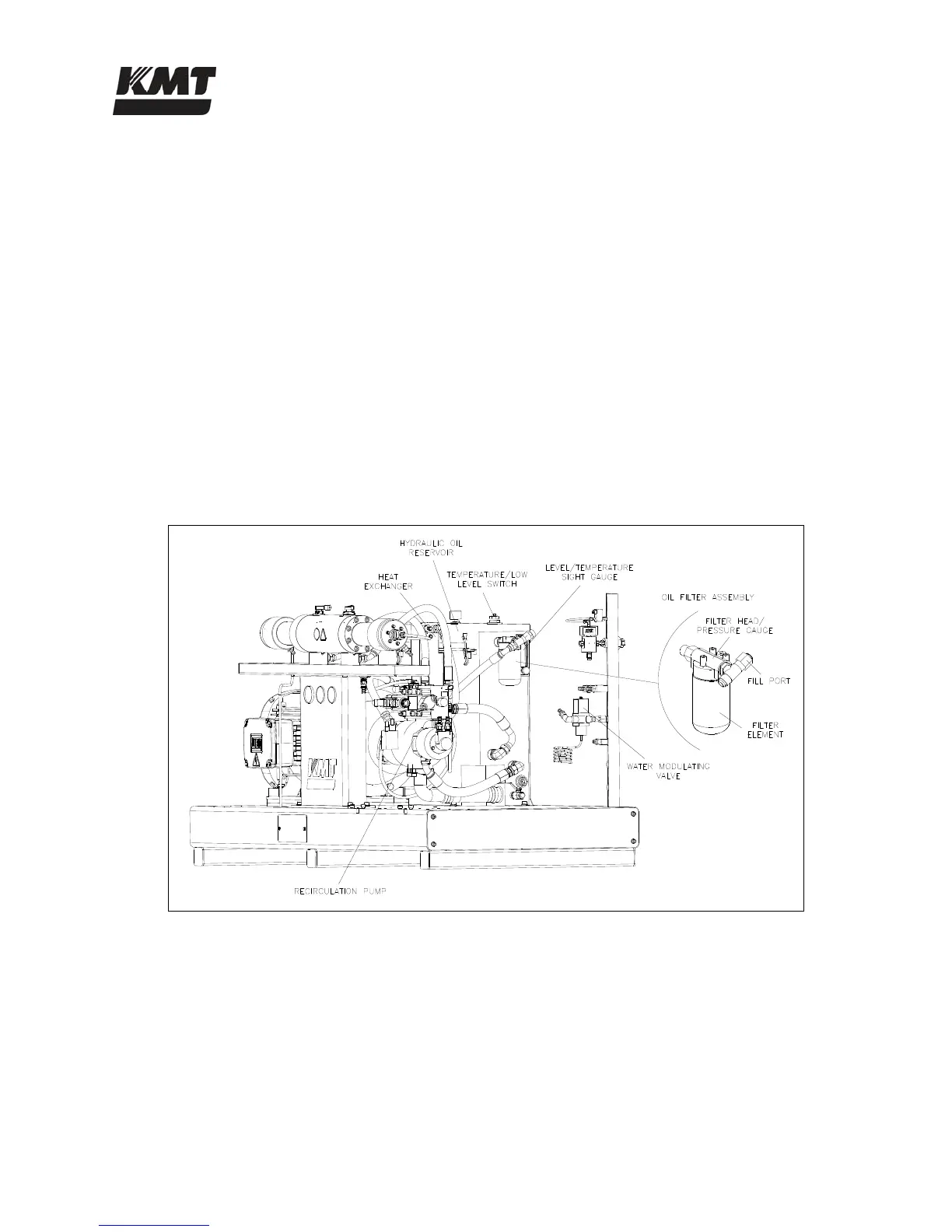

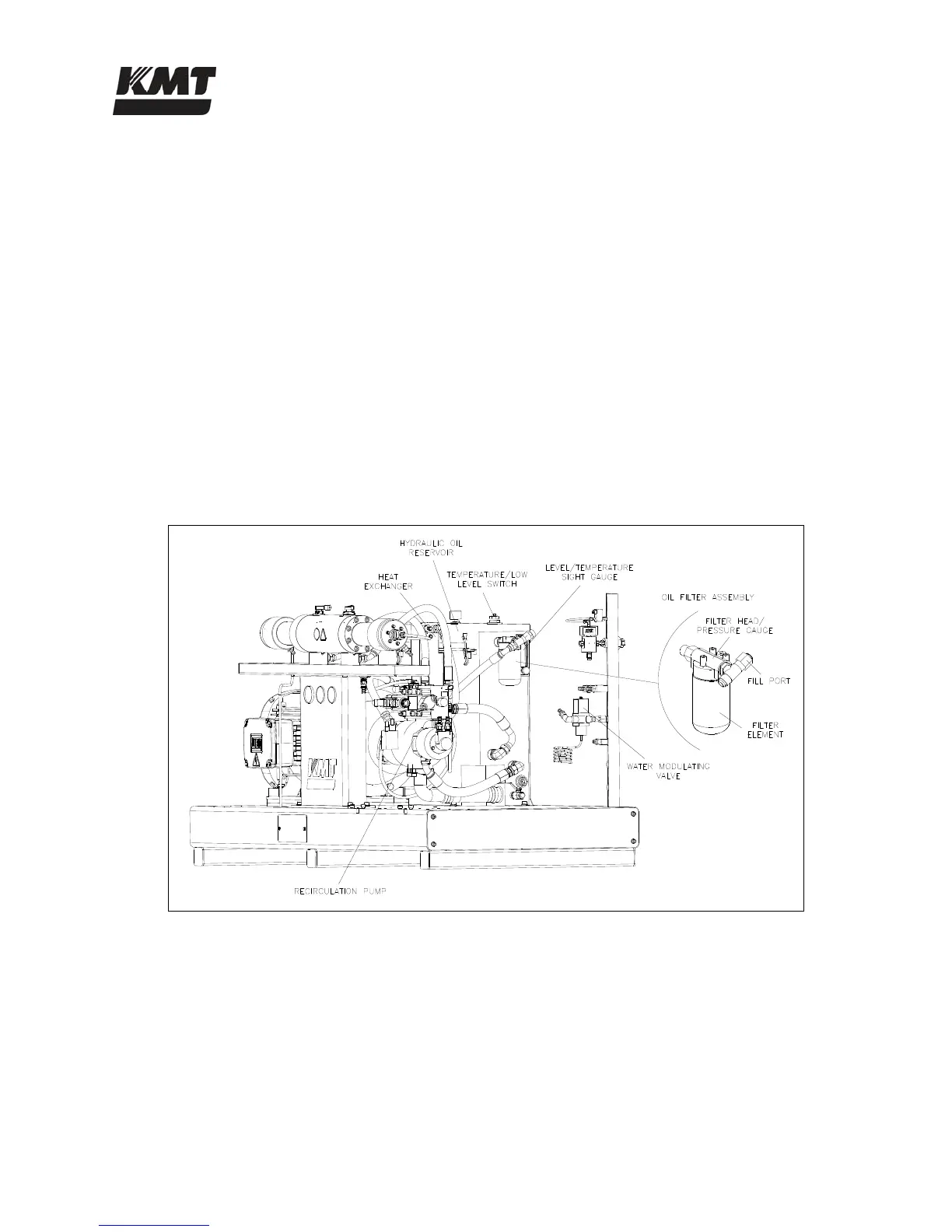

Figure 5-1: Recirculation System Components (Oil-to-Water)

The recirculation pump pulls oil from the reservoir and sends it to the heat exchanger. The oil-to-

water heat exchanger controls heat build-up in the hydraulic oil. The plate style design allows

cooling water and oil to flow side by side through alternating plates.

The cooled oil then passes through the filter element and returns to the reservoir. The cooling

water either is discharged to the 1/2-inch NPT drain on the bulkhead or is routed to a customer

supplied water chiller.

The hydraulic oil filter assembly consists of the filter head, a filter element, pressure gauge,

bypass relief valve and the oil fill port. The filter element should be changed when the gauge

reads 40 psi (2.8 bar) at normal operating temperature.

Loading...

Loading...