Section 8

High Pressure Water System

20479291

2-2012/Rev 04

8-16

5. Use the wrench or socket to tighten the poppet retainer screw. Tighten the poppet retainer

screw to the torque specifications in Table 8-1.

6. Inspect the assembled unit to ensure the poppet moves freely and the poppet retainer

screw is seated.

Sealing Head Maintenance

The sealing head should be inspected for scratches, excessive sealing damage or erosion marking

on the cone ring contact surface, and on the inlet poppet valve contact surface. If defects are

detected, the surfaces must be refinished. The sealing head can be returned to KMT Waterjet for

refinishing.

1. Clean the surface on the cone ring with 600-grit wet/dry sandpaper, using a radial motion.

It will not be possible to fully remove the main sealing marks.

2. Inspect the inlet poppet valve sealing surface for pits, scratches or jetting erosion. If

necessary, refinish the surface.

Place a piece of 1/4-1/2” thick plate glass, not window glass, on a sturdy table to provide

an absolutely flat surface. Place a piece of 400-grit wet/dry sandpaper on the glass. Use

even, deliberate strokes, rotating the sealing head approximately 10-15 degrees after each

stroke. Polish the sealing head until it is flat and smooth. Be careful not to cause

additional damage by tilting or tipping the part while polishing.

3. When the sealing head is flat and smooth, perform a final polish with 600-grit wet/dry

sandpaper.

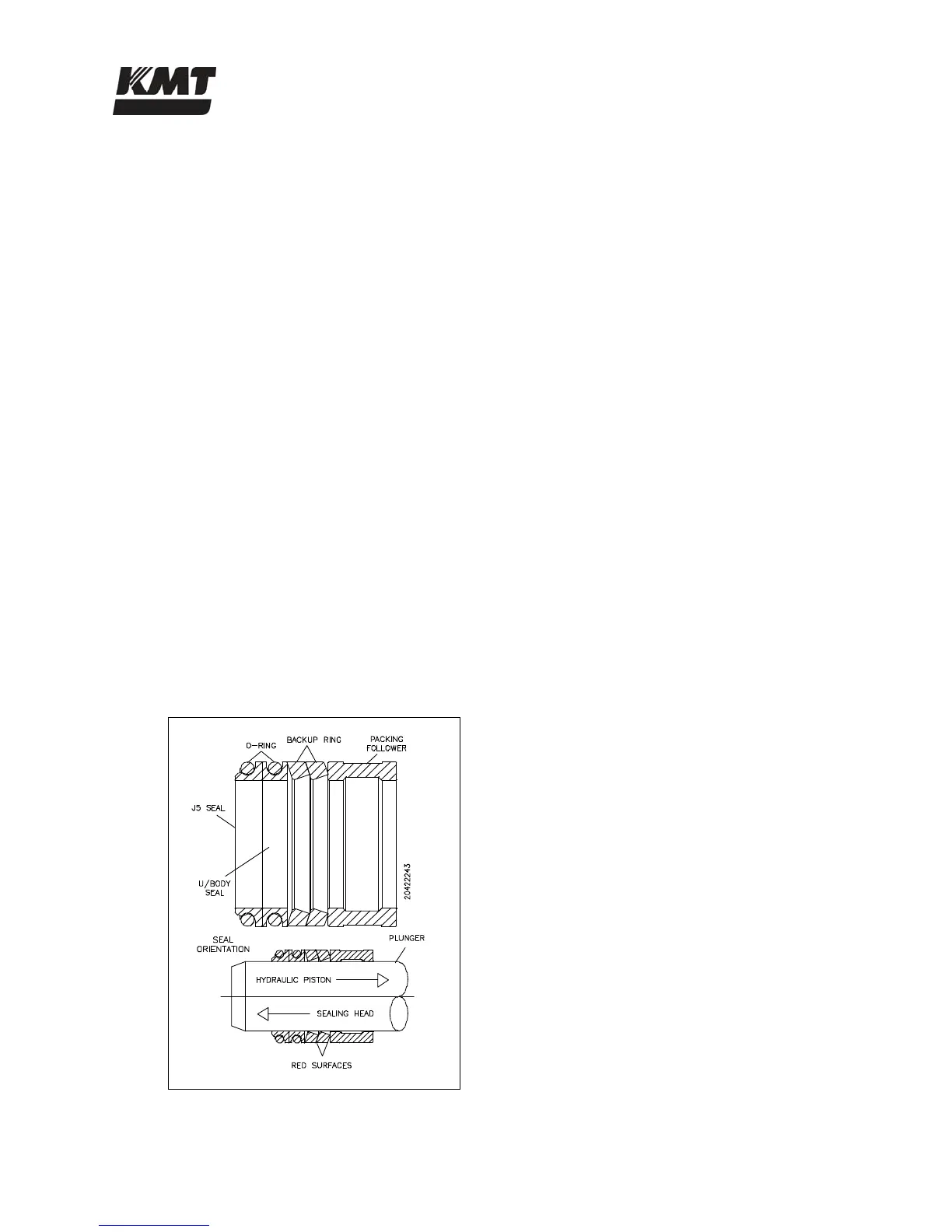

8.9 High Pressure Seal Assembly

The following procedure should be used to replace the high pressure seal assembly.

Figure 8-13: High Pressure Seal Assembly

Loading...

Loading...