Section 8

High Pressure Water System

20479291

2-2012/Rev 04

8-17

Prior to removing electrical power or any high or low pressure piping, start the machine and extend the

plunger on the end to be serviced to allow full exposure when the unit is disassembled.

1. Turn the machine off and observe the appropriate Lockout/Tagout procedures.

Severe injury can result if the machine is not properly locked out. Observe

electrical Lockout/Tagout procedures before proceeding.

Ensure all pressure is relieved or blocked from the hydraulic and high pressure

circuits before proceeding.

2. Disconnect the high and low pressure water piping, following the procedure, High and

Low Pressure Water Piping.

3. Remove the high pressure cylinder assembly, following the procedure, High Pressure

Cylinder Assembly Removal.

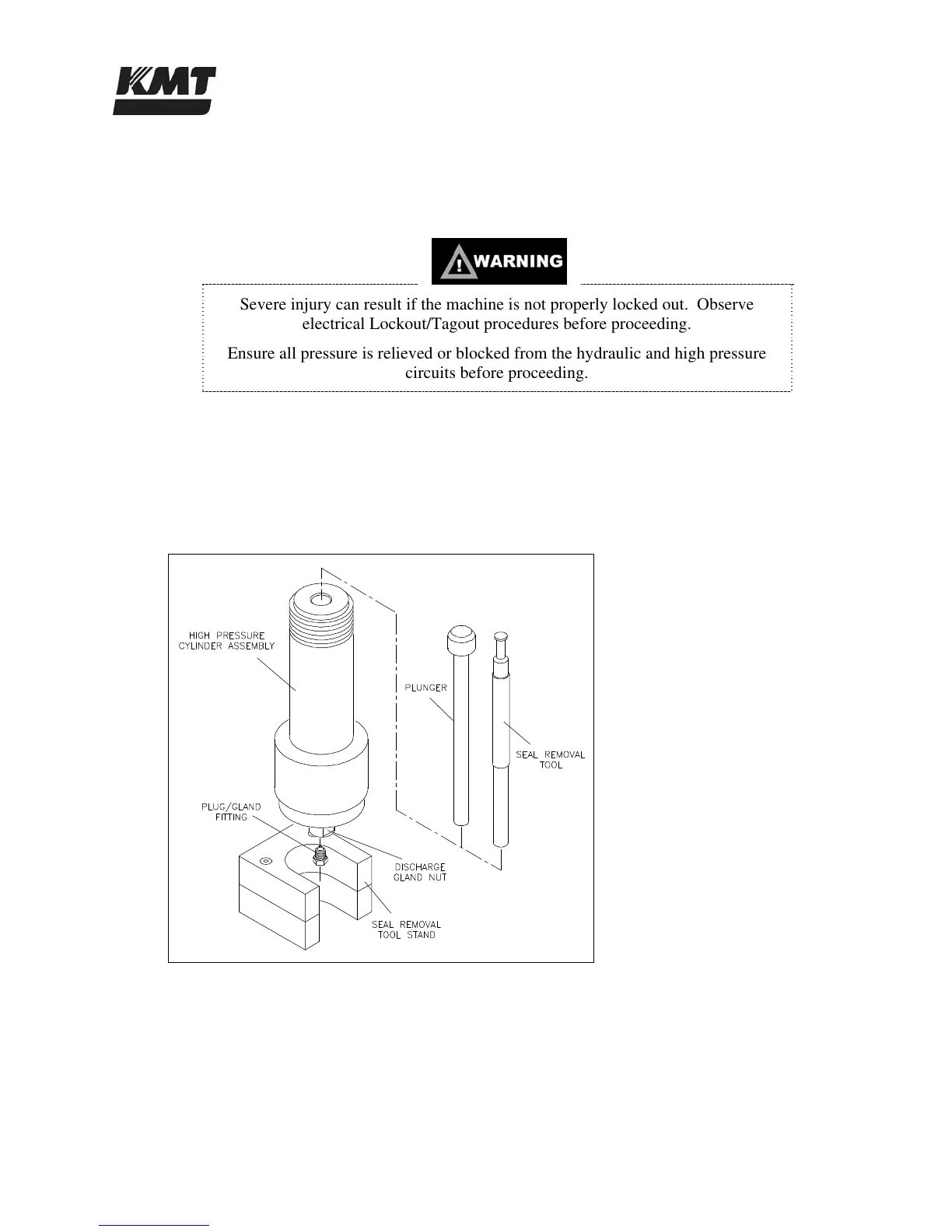

Figure 8-14: High Pressure Seal Removal

4. Apply Pure Goop to the threads on the high pressure plug and gland fitting. Thread the

plug and gland fitting into the discharge gland nut on the sealing head and hand tighten.

5. Position the cylinder assembly upright in the seal removal tool stand. If a tool stand is not

available, position the cylinder on a platform of wooden blocks with the jackbolts resting

on the platform.

Loading...

Loading...