Section 9

Troubleshooting

20479300

2-2012/Rev 01

9-8

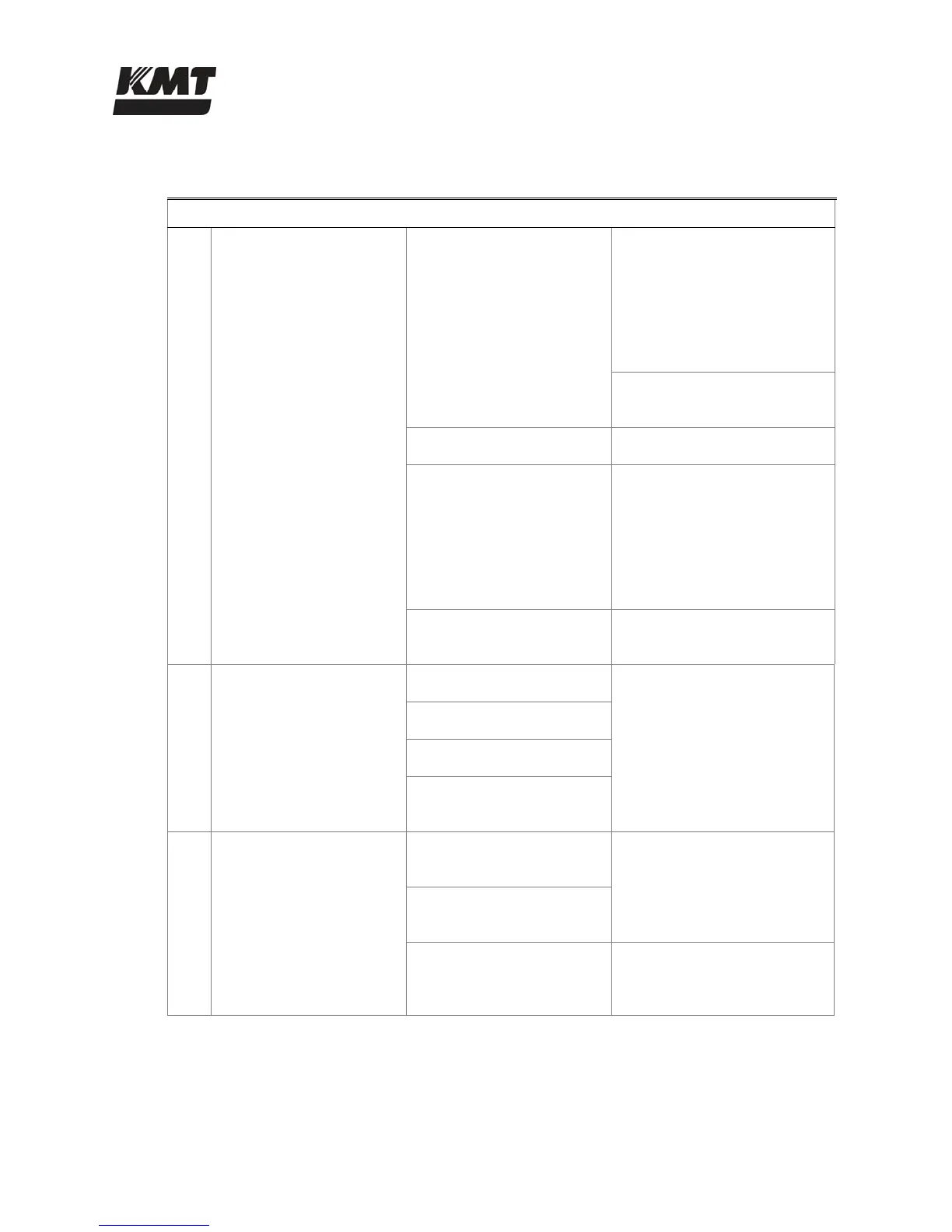

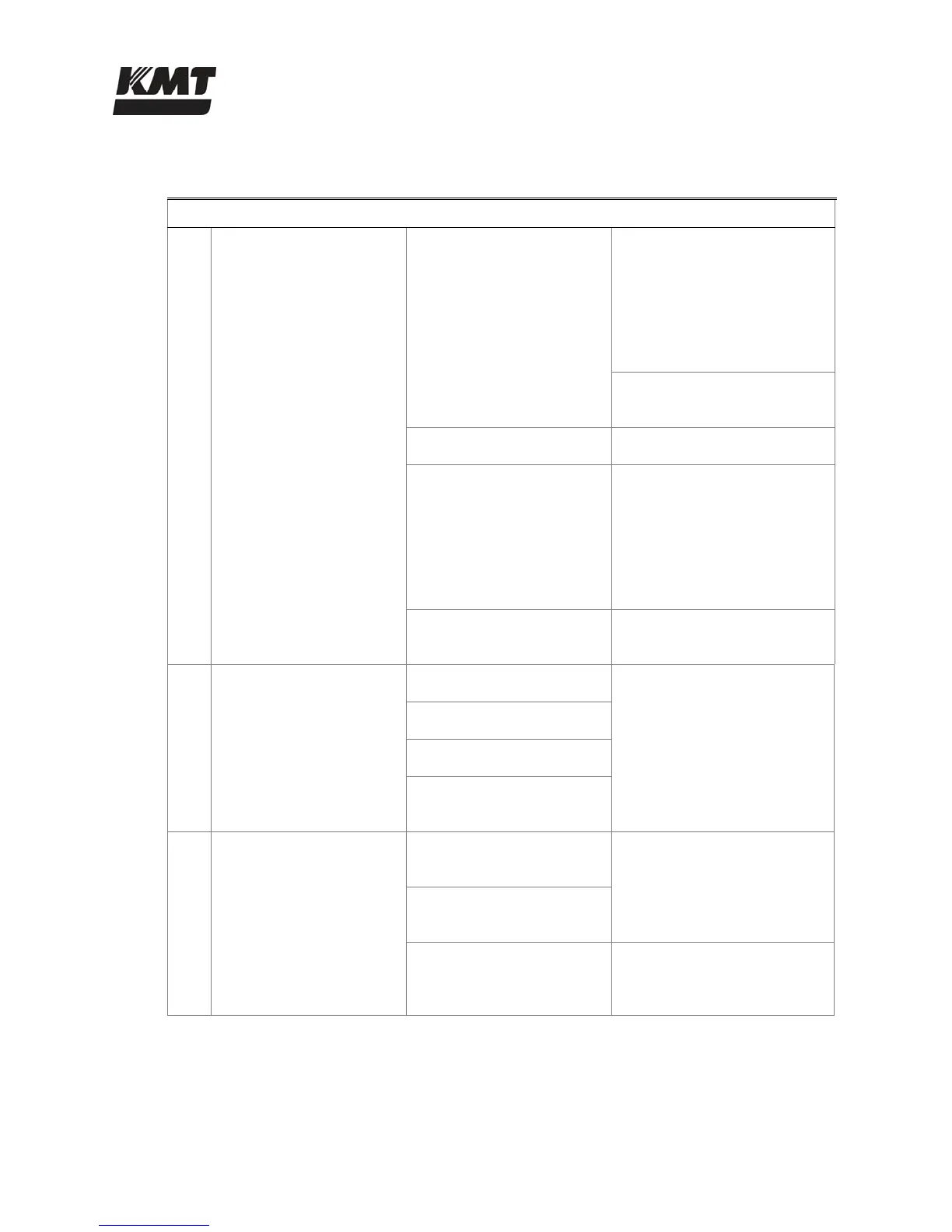

Table 9-1

S50 Troubleshooting Guide

Malfunction Indication Comments

17.

Water leaking from the

weep holes in the hard seal

end cap

Damaged high pressure

cylinder

Check for scratches or grooves

on the coned seal surface. If

detected, polish to remove

following the procedure, High

Pressure Cylinder Maintenance,

detailed in Section 8, High

Pressure Water System.

Replace the high pressure

cylinder.

External crack in sealing head Replace the sealing head.

Damaged sealing head Check for scratches or grooves

on the coned surface of the

sealing head. If detected, polish

the surface following the

procedure, Sealing Head

Maintenance, detailed in Section

8, High Pressure Water System.

Improper torque on jackbolts Re-torque the jackbolts to the

proper torque specification.

18.

High boosted water

temperature

Orifice is blocked with debris

Long deadhead condition

Insufficient water supply

Booster pump temperature

switch malfunction

19.

Booster pump pressure drop

is greater than 30 psi (2 bar)

during stroke condition

Inlet water pressure or flow is

low

Filter element is dirty and

needs to be replaced

Booster pump is starting to

fail

If the pressure consistently

drops below 60 psi (4 bar) the

pump will need to be replaced.

Loading...

Loading...